BLDC Motor, Advantages, Disadvantages, Applications, Working

Hello guys, welcome back to our blog. In this article, we will discuss BLDC motor, the advantages of BLDC motor, the disadvantages of BLDC_motor, the applications of BLDC motor, and the working of BLDC motor.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- DC Motor, Advantages, Disadvantages, Applications, Working.

- Universal Motor, Advantages, Disadvantages, Applications, Working.

- Stepper Motor, Advantages, Disadvantages, Applications, Working.

BLDC Motor

The main purpose of a motor is a conversion of electrical energy to mechanical energy. A mechanical force is experienced when a conductor is placed in a magnetic field. The direction of the conductor is given by Fleming’s left-hand rule.

BLDC Motor:- BLDC-Brushless DC motor. It is a synchronous motor that uses direct current as an electric power supply. It uses some electronic devices such as closed-loop controllers to switch the DC supply.

Construction Of BLDC Motor

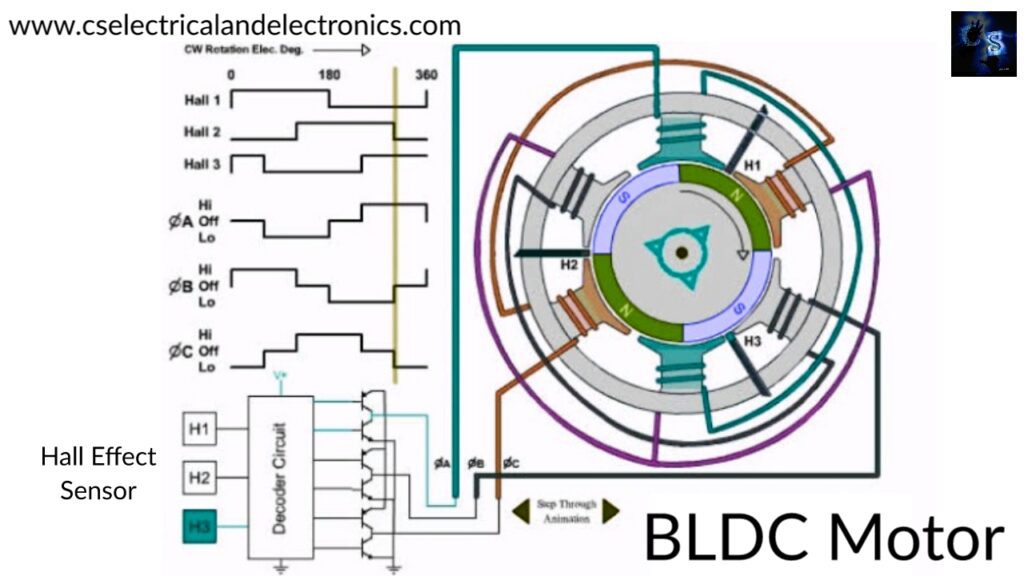

Semiconductor control is used for controlling the stator current in such a way that maximum torque is obtained at a given speed. The stator has three-phase winding while the rotor is in the form of a permanent magnet.

The rotor is the part of the machine that will rotate and the stator is the part of the machine that will remain constant in the stationary part of the machine.

Speed can be controlled by controlling the stator of the machine which can be achieved by controlling the dc input voltage of the inverter. The shaft is the rotating part that is connected to the different types of load driven by the motor.

BLDC motor also consists of rotor position sensors that produce electrical signals that indicate the current position of the rotor. The stator winding of the BLDC motor is driven by an electronic drive which is a three-phase inverter.

The permanent magnet brushless DC motors use Hall sensors with 60 degrees of electrical spacing. These sensors produce a logic 1 when exposed to the N-type of the rotor and logic 0 otherwise.

In the BLDC motor,

- The fields produced by the stator and rotor remain stationary with respect to each other.

- The driver circuit operates on a dc supply.

This motor does not have brushes.

Principle Of Operation Of BLDC Motor

When a stator winding is connected with three phases input supply is given to the winding then the current will be produced across the stator that the rotor will rotate in a particular direction.

When energizing one of the phases, stator poles south and north are created. Stator S poles repel rotor S pole and attract rotor north pole. Clockwise torque is produced since there is a field produced by the magnet and the magnet is rotated by the phase poles.

The magnitude of stator field flux is proportional to stator current and the rotor field is constant. The stator phase is energized in the sequence of R, Y, B, and R so as to have a clockwise rotation of the machine.

Advantages Of BLDC Motor

- 01. The absence of brushes reduces the frequent replacement of brushes which reduces the maintenance cost.

- 02. A Brushless DC motor has high-level control over the speed and position of the motor.

- 03. The lifespan of a Brushless DC motor is higher than the brushed DC motor.

- 04. Sparking is reduced due to the absence of brushes and there is a few chances of burnout due to sparking issues.

- 05. A Brushless DC motor provides high torque to speed ratio which is best suited for robotics and medical applications.

- 06. As there is no electromagnet in the Brushless DC motor hence the heating issue is being reduced.

- 07. It follows a feedback control system that has the ability to modify and control the speed and torque.

- 08. These motors are suitable to run either in a low load or no load.

- 09. As there are no brushes it produces less operating noise.

- 10. These motors are used in electrical applications where less noise is required.

Disadvantages Of BLDC Motor

- 01. Brushless DC motors are operated at relatively low speeds. Due to this low-speed vibrations occurs in the system.

- 02. The cost of these motors is high.

- 03. As these motors consist of a feedback loop the wiring and operation are not that simple.

- 04. It requires an electronic switching controller to switch the voltage to the motor coils.

- 05. As the Brushless DC motor doesn’t consist of the commutator, it will require some special electronic device.

- 06. It needs three hall effect sensors to measure rotor position.

Applications Of BLDC Motor

- 01. Brushless DC motors are used in hybrid vehicles, electric vehicles, and other electrical equipment.

- 02. These motors are used in robotics for robotic arms.

- 03. BLDC motors are used in computer hard drives and DVD players.

- 04. These motors are used in fans, washing machines, dryers, pumps, blowers, and compressors.

I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Automotive Interview Questions With Answers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

well explained the article in a simple way covering all the aspects. This is the finest articles.