Hello guys, welcome back to our blog. In this article, we will discuss what is an electric drive, working, its applications of electric drive, its advantages, disadvantages, and components used in electric drive.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- What Is Smart Grid, Working, Applications, Requirements Of Smart Grid?

- Cost Of Electric Cars In USD And Indian Rupees, Electric Car Price.

- How To Become An Electrical Contractor, Electrical Contractor License.

What Is Electric Drive

The electrical drive is the form of equipment that is used to control the motor efficiently based on requirements. The equipment which consists of controllers, and sensors used to control the motor is called the electrical drive. Mainly electrical drives are used for motion control. Electrical drives consist of different parts the electrical motor is the heart of the drive.

The motion control of the electrical load depends on the speed and torque. The motors used in the electrical drives will be chosen according to the load. The electrical drive is used as per the torque and speed requirement by controlling them using different parts in it.

Every time when the name electrical motor or electric generator is done, we intend to think that the speed of revolution of these machines is totally controlled just by the employed voltage and frequency of the source current.

However, the speed of rotation of an electrical machine can be controlled precisely also by performing the concept of the drive. The main benefit of the concept is the motion control is easily optimized with the help of the drive.

Well, guys, we can also state that the system which controls the motion or rotation of the electrical motor is called an electrical drive. A typical drive system is modeled with an electric motor and a sophisticated control system that controls the rotation of the motor shaft.

Nowadays, this control can be easy with the software, so the controlling becomes more and more realistic and this concept of drive also provides ease of use. In simple words means, the drive and system is a circuit that is designed to control the motor based on the requirements.

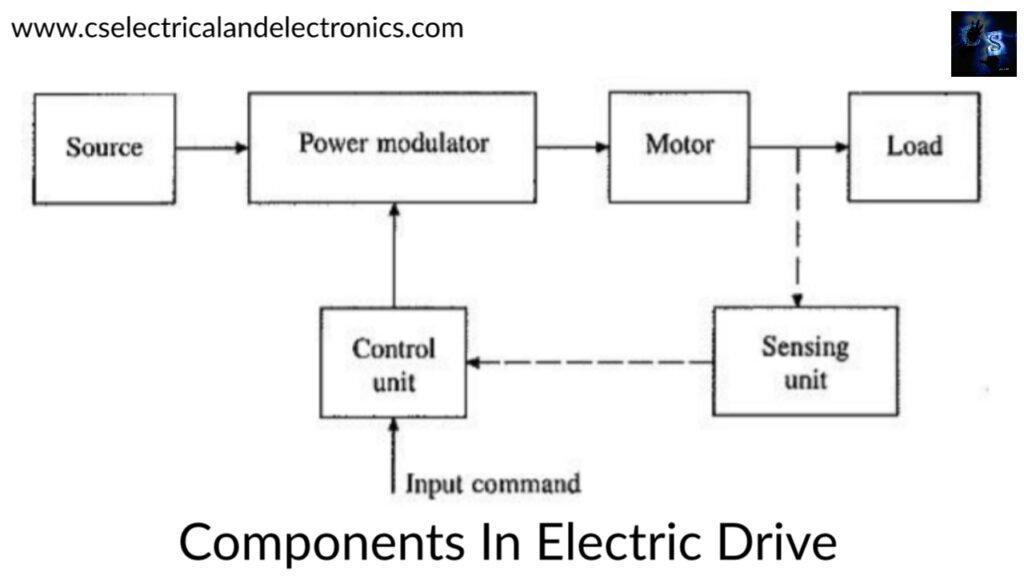

Components In Electric Drive

The power modulator, motor, sensing unit, and controlling units are the main components of the electrical drive. Every part has its own importance of work in the electrical drive.

01. Power Modulator

The key role of the power modulator is to control the input power source coming to the motor. The power modulator will control the input power source in such a way that the output will be the speed-torque characteristics required. The excessive current will be drawn for the motor during the braking and other operations. The power modulator will control this type of overload conditions and current to the motor.

The power modulator also works as the converter respective to the motor and the input source. For example, if the input is ac and the motor used is a Dc series motor then the power modulator will be operated and converts ac input into dc and send it to the input source for the motor. This is the role of the power modulator in the electrical drive.

02. Motor

The motors are used according to the application required. The various motors are used for electrical drives with reference to the load used. In the majority of cases, the electrical drives consist of the DC motors as the controlling process of these motors will be done with ease.

As the drives are majorly used in medium and large industries, three-phase induction motors are also used. The motor part is the main part of the electrical drive. So the motor is called the heart of the electrical drive.

03. Sensing Unit

The sensing unit is used for the protection and feedback for the closed-loop operation. It is used to sense the parameters required for the output. The motor speed and the torque are the main parameters that are sensed using the sensing unit. The sensed output will be given to the control unit hence the input will be controlled according to the feedback given. This is the main operation of the sensing unit.

04. Control Unit

The main operation of the control unit is to give feedback and control the power modulator to improve the efficiency of the electrical drive. The control unit helps to achieve the desired output by controlling the power modulator and the input power source. The commands are given to protect the system using the sensing system from the control unit. The electrical drive controls will be done by the control unit.

This is how the electrical drive operates using different types of components in the drive.

Advantages Of Electric Drive

- The driver possesses a high range of torque and speed.

- The losses are less hence the drive is of high efficiency.

- The starting of the drive is very easy and any of the resources are not used.

- The flexible control of the drive made the efficiency high.

- These are independent of weather conditions.

Disadvantages Of Electric Drive

- The applications of the drive are limited as the power supply required to drive is very high.

- The noise pollution is comparatively high.

- The initial cost is very high as the construction is somewhat complex.

- The braking system of the electrical drive can cause the wearing and tear of the rotating elements.

- The current drawn will be high in overload conditions.

Application Of Electric Drive

The applications of electrical drives are in different systems such as transport, domestic and industrial.

- In the transport system, the electrical drives are used in the traction and buses.

- Coming to domestic applications it is used in washing machines, air conditioners, and other appliances.

- In industries the spinning wheels, conveyor belts, extruders, trolleys, etc., there are so many different applications in the industrial sector using electrical drives.

This was about “What Is Electric Drive“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 100+ Indian Startups & What They Are Building

- 1000+ Automotive Interview Questions With Answers

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024