What Is Core Type And Shell Type Transformer, Difference Between

Hello Guys, welcome back to our blog. In this article, we will discuss what Is core type and shell type transformers, the construction of core & shell type transformer.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- Top 100 Electrical Companies In The World Where You Can Work

- What Is Unified Power Flow Controller (UPFC), Purpose, Applications

- Top 12 Electrical Switch Manufacturing Companies In The World

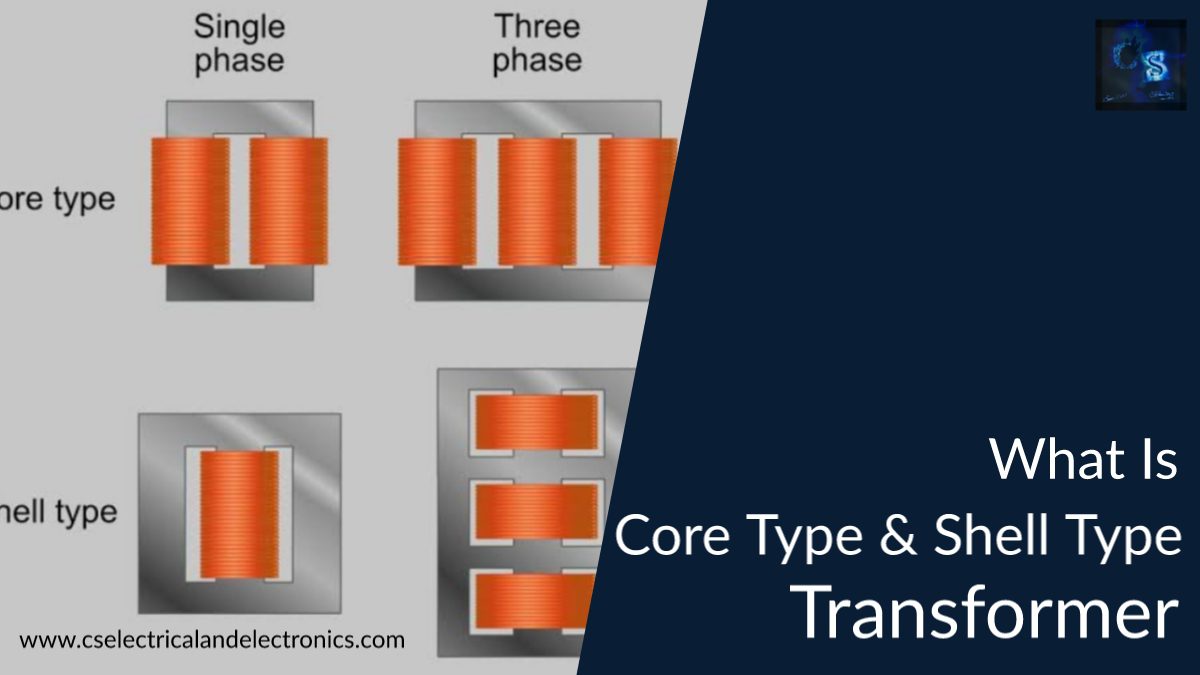

Core Type And Shell Type Transformer

Topics To Be covered?

- 01. What is the core type transformer?

- 02. What is the shell type transformer?

- 03. Construction of core type transformer?

- 04. Construction of shell-type transformer?

What Is Core Type Transformer?

A core type transformer is a type of transformer that consists of a single magnetic circuit and has two limbs (limbs mean a vertical portion of the core is called a limb). In this type of transformer two coils are placed separately on a different limb. For high voltage and low rating, core-type transformers are used. In the case of the core type, natural cooling is possible.

What Is A Shell Type Transformer?

A shell-type transformer is also a type of transformer that consists of a double magnetic circuit and it has three limbs. But coils are placed on one limb i.e., the central limb. For low voltage and high ratings, a shell-type transformer is used. Cooling is not effective in shell type.

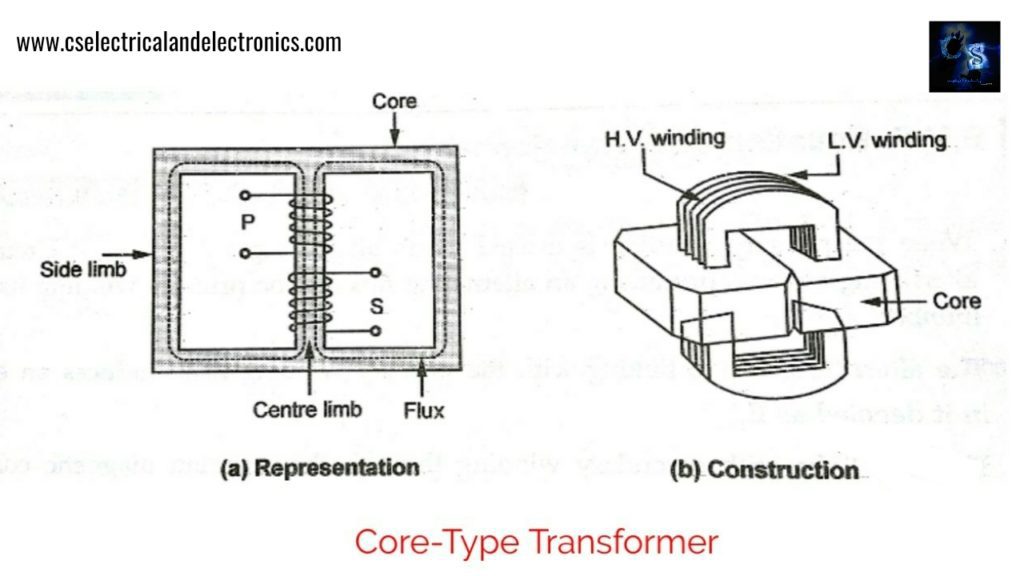

Construction Of Core Type Transformer

Now I will discuss step by step how core-type transformers are constructed.

- 01. The figure shows a schematic representation of the core-type transformer whereas figure b shows the actual view of the core-type transformer.

- 02. The coils used are of cylindrical type, wound in helical layers with different layers insulated from each other by using insulation like paper or mica.

- 03. Both the coil of cylindrical type are placed on both the limbs, the low voltage coil is placed near to the core whereas the high voltage coil is placed above the low voltage coil to reduce insulation cost. Now I will explain how it will reduce costs. Consider, two cases:

Case 01: Low voltage winding near to limb and a transformer of 110 kV / 33 kV.

Total insulation required to withstand voltage = Insulation required to withstand voltage near core + Insulation required to isolate high and low voltage winding

= 33 KV + (110 – 33)

= 33 + 77

= 110 KV

Therefore, if low voltage winding is placed on a limb first, then the insulation required is to withstand 110 kV voltage.

Case 02: High voltage winding near the limb.

Total insulation required to withstand voltage = Insulation required to withstand voltage near core + Insulation required to isolate high and low voltage winding

= 110 kV + (110 – 33)

= 110 + 77

= 187 kV

Therefore, if high voltage winding is placed on a limb, then the insulation required is to withstand 187 kV voltage.

So, always low voltage winding is placed near the core. If the voltage is more then more insulation is required which increases the cost.

- 04. The core in the transformer is made up of thin laminations.

- 05. By removing the top yoke (yoke means the horizontal portion of the core is called yoke) the coil can be removed easily for maintenance.

- 06. Interleaved connections of coils are made. Interleaved connected means part of the primary winding is placed on the first limb and also on the second limb & the part of the secondary winding is placed on the second limb and also on the first limb to avoid leakage flux. If the primary coil is placed only on one limb then leakage flux will be more to avoid leakage flux interleaved connections being made.

- 07. Concentrated winding means both the coils(low voltage winding and high voltage winding) of the transformer are placed one over the other by providing proper insulation.

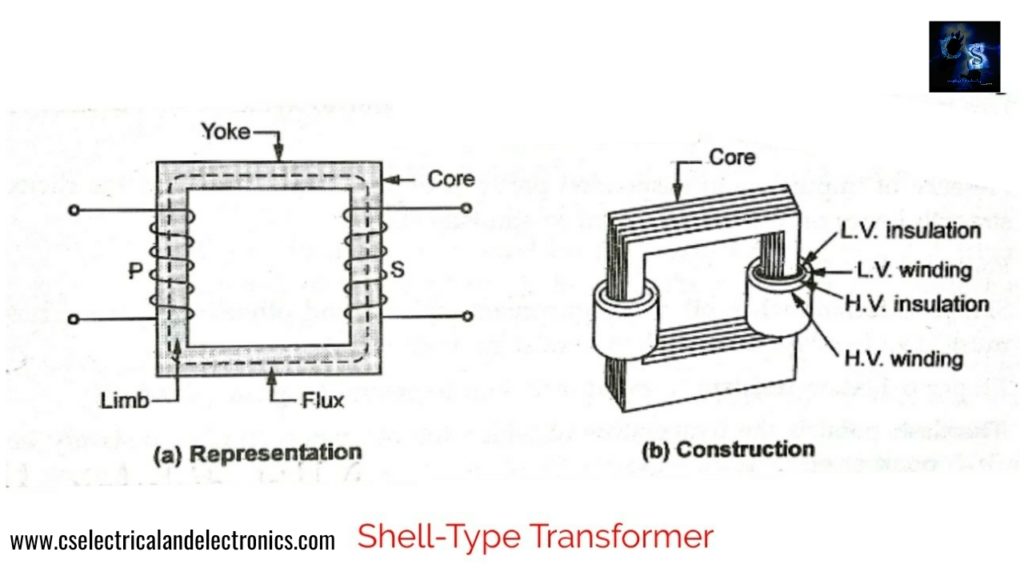

Construction Of Shell Type Transformer

- 01. In this type of transformer, both coils are placed in the central limb. This type of transformer consists of 3 limbs.

- 02. In this type of transformer, sandwich coils or multilayer disc type coils are used. sandwich coils mean that in the middle limb, some part of the primary winding is wounded and then some part of the secondary winding is wounded then after secondary winding again some part of the primary winding is wounded then again secondary winding is wounded this method is called a sandwich winding or we can also say alternate layers of primary and secondary coils wound on the central limb.

- 03. In the case of the sandwich type of winding, the insulation requirement is more compared to the core type of winding.

- 04. For high voltage transformers, the shell type of transformer is most preferred.

- 05. If you want to remove the coil for maintenance then a large number of laminations you need to remove.

- 06. Figure (a) shows representation and figure(b) shows an actual view of a transformer.

This was about “Core Type And Shell Type Transformer“. I hope this article may help you all a lot.

Tags: What Is Core Type And Shell Type Transformer, Construction.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Automotive Interview Questions With Answers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students