Types Of Insulators Used From Service Mains To Transmission

Hello Guys, welcome back to our blog. Here in this article, we will discuss different types of insulators used from service mains to transmission lines or different types of insulators used in the overhead line.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read the following:

- Scientists Develop An AI Model That Can Read The Human Mind

- What Is Python Scripting, Purpose, Applications Of Python Script

- Top 20 Ocean Technologies That Will Blow Your Mind

Different Types Of Insulators

The insulators which are used from service mains to transmission lines are as follows :

- Reel Insulators

- Break Insulators

- Disc Insulators

- Pin Insulators

- Guy Insulators

- Suspension Insulators

- Strain Insulators

1. Reel Insulators

Reel insulators are used in overhead service mains, it is made up of porcelain material and the diameter of the reel insulator is 12.5 mm. The function of reel insulators is to maintain distance between cables that are used in service mains.

If the service cables are drawn without providing reel insulators after some time the insulation may damage due to the heat of the sun or rain and then the conductors will come in contact with each other and the fault will occur. So if we provide reel insulators even though the insulation may get damaged there will not be any fault or short circuit in service mains.

2. Break Insulators

Break insulators are also used in overhead service mains, it is also made up of porcelain material. In overhead service mains, only two break insulators are used of the 1.1 KV class. The break insulator is used in overhead service mains at the pole side and at the service pipe side. The purpose of the break insulator is to isolate the messenger wire from the pole and from the service pipe.

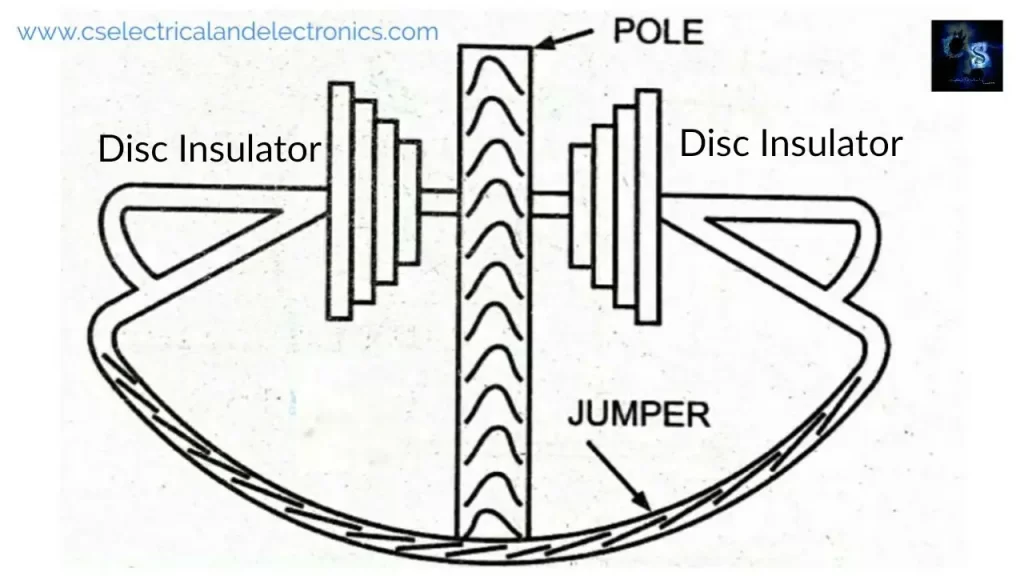

3. Disc Insulators

Disc Insulators are used in low-tension (HT) lines and high-tension (HT) lines. It is also made up of porcelain material. The disc insulators are only used at starting pole, dead-end pole, and anchoring pole. It is also used to make suspension and strain insulators.

Salient Features of Disc Insulators

- The head portion of the ball pin and cap is suitably designed so that when the insulator is under tension the stresses are uniformly distributed as compression over the pinhole portion of the shell.

4. Pin Insulators

This is the first developed insulator and is being used for overhead lines for voltage grades up to 33 kV. The live conductor is placed on the top of the insulator and the bottom of the insulator is connected to the earth. The insulator should withstand the potential stress between the earth and the conductor. when the insulator is wet due to rain, its outer surface becomes almost conducting like a conductor.

Hence, the flashover distance of the insulator is decreased. The electrical insulator is designed such that the decrease of flashover distance is minimum when the insulator is wet.

That is why the uppermost petticoat of a pin insulator has an umbrella type designed so that it can protect the rest lower part of the insulator from rain.

The upper surface of the topmost petticoat as shown in the above figure is inclined as little as possible to maintain maximum flash over high voltage during rain.

5. Guy Insulator

The guy insulator is also made up of porcelain material. The type of insulator is used in LT lines and in Guy set. Guy insulators are used in the LT line only at starting pole and dead-end pole and the guy insulator used in the guy set is to isolate the GI wire from the pole and from the ground.

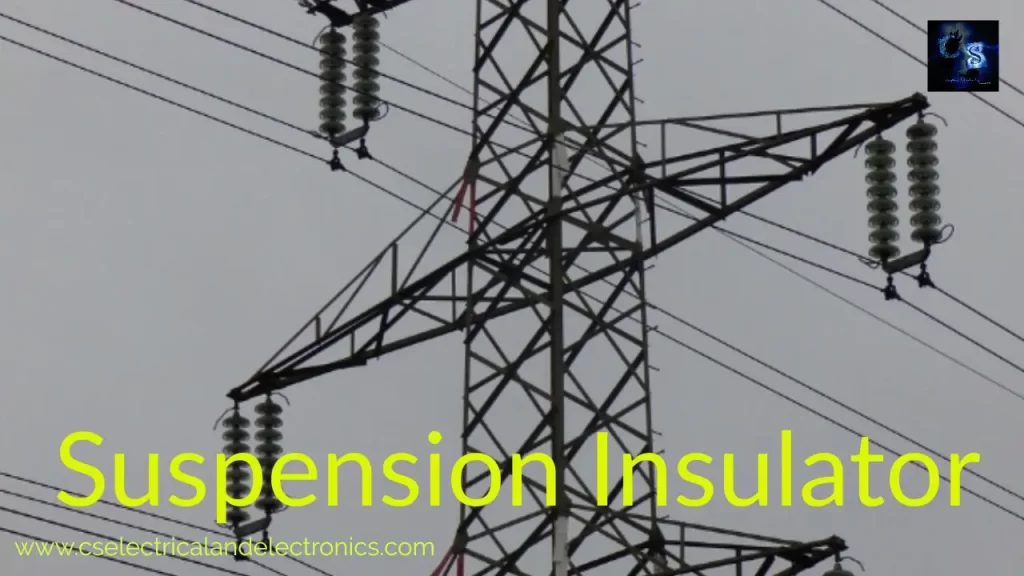

6. Suspension Insulators

The suspension insulators are made up of a number of disc insulators. If the number of disc insulators is connected in series then it will become suspension insulator and strain insulator.

Both suspension insulator and strain insulator looks the same but the use of insulators is different. The suspension insulator is used in every tower. The suspension insulator is always parallel to the tower and perpendicular to the ground. The number of disc insulators to make a suspension insulator depends upon the line voltage.

If the line voltage is 33 kV then 3 disc insulators are used to make suspension insulators, if the line voltage is 66 kV then 6 disc insulators are used to make suspension insulators, and so on.

7. Strain Insulators

The strain insulators are also made up of a number of disc insulators. The strain insulator is always parallel to the ground and perpendicular to the tower. The number of disc insulators to make a strain insulator depends upon the line voltage.

If the line voltage is 33 kV then 3 disc insulators are used to make a strain insulator, if the line voltage is 66 kV then 6 disc insulators are used to make strain insulators, and so on.

I hope this article may help you all a lot. Thank you for reading. If you have any doubts regarding this article “Different types of insulators” then comment below.

Tag: Different types of insulators.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024