Safety Standards For Battery Management (BMS) In Electric Vehicle

Hello guys, welcome back to our blog. In this article, I will discuss the types of safety standards for battery management systems (BMS) in electric vehicles and how they affect the system.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

Also, read:

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- No Electric Vehicles For The Next 10 To 15 Years In India?

- What Are MAAB Guidelines, Important For MBD Engineer

Safety Standards For Battery Management (BMS)

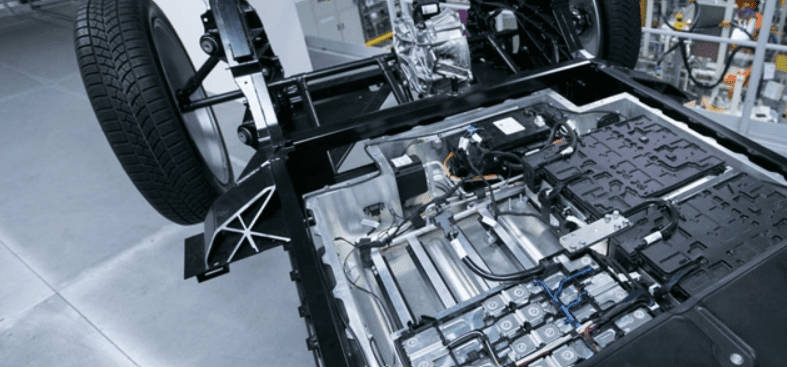

Battery Management Systems (BMS) are at the heart of electric vehicle (EV) safety, ensuring the efficient and reliable operation of lithium-ion batteries. As batteries become more powerful and complex, maintaining their safety, performance, and longevity is critical. Various safety standards have been established to address these challenges, focusing on aspects such as functional safety, electrical and thermal safety, cybersecurity, and environmental reliability. By adhering to these standards, manufacturers can mitigate risks, prevent failures, and enhance consumer trust in electric vehicles.

Each safety standard plays a vital role in safeguarding battery systems and the broader electric vehicle ecosystem. From ISO 26262’s focus on functional safety to ISO/SAE 21434’s emphasis on cybersecurity, these guidelines ensure that BMS solutions meet the highest levels of safety and performance. This comprehensive approach not only protects the vehicle and its occupants but also supports the global shift toward sustainable and electrified mobility.

01. Functional Safety Standards (ISO 26262)

Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle, mitigating risks that could compromise the system’s reliability and safety.

ISO 26262 is a key standard for automotive functional safety, focusing on electrical and electronic systems, including BMS. It outlines safety requirements to manage risks associated with the design, implementation, and operation of BMS.

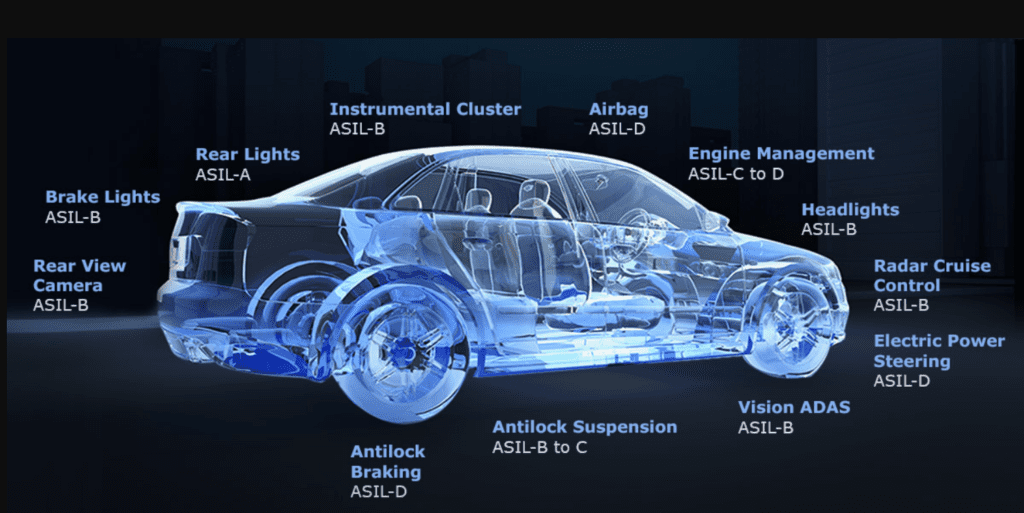

Automotive Safety Integrity Levels (ASIL) are defined within ISO 26262 to categorize the degree of risk associated with each system function. Higher ASIL levels demand more stringent safety measures.

Hazard analysis and risk assessment processes form the core of ISO 26262, identifying potential hazards and determining appropriate safety measures.

IEC 61508 provides a generic framework for functional safety, applicable to various industries. It serves as the foundation for automotive-specific standards like ISO 26262, ensuring consistency across sectors.

Safety requirements for the BMS are also defined by these standards, encompassing aspects such as fault tolerance, fail-safe operation, and risk mitigation strategies to ensure safe system functionality.

These standards are critical to ensuring that any faults within the BMS do not lead to catastrophic failures, protecting both users and the vehicle from hazards. Compliance with these guidelines assures that a system can function safely under normal and fault conditions, minimizing risks.

02. Electrical Safety Standards

Electrical safety standards focus on preventing electrical hazards in BMS by ensuring proper design, testing, and operation of electrical components to reduce the risk of electrical failures.

UL 1973 outlines safety standards for stationary and motive applications, including BMS in electric vehicles (EVs). It emphasizes the importance of safe design and construction practices to prevent electrical failures.

IEC 62619 focuses on safety requirements for secondary lithium batteries used in industrial applications, including EVs. It defines electrical safety protocols necessary for the BMS to ensure proper operation and protection of battery cells.

IEC 60950 applies to the electrical safety of equipment such as BMS in electrical products. It establishes criteria for the safe design and construction of electronic equipment.

IEC 62368 is an alternative to IEC 60950, focusing on the safety of audio/video, information, and communication technology equipment, including BMS. It sets safety standards for electrical and thermal hazards.

These standards ensure that the electrical systems within a BMS are safe to use, reducing the risks of electrical fires, short circuits, and other hazards that could arise from improper electrical handling.

Electrical safety standards are vital to ensuring that the battery system functions without causing harm to users, infrastructure, or the environment. A BMS adhering to these standards will be able to prevent unsafe conditions related to overvoltage, undervoltage, or short circuits.

03. Thermal Safety Standards

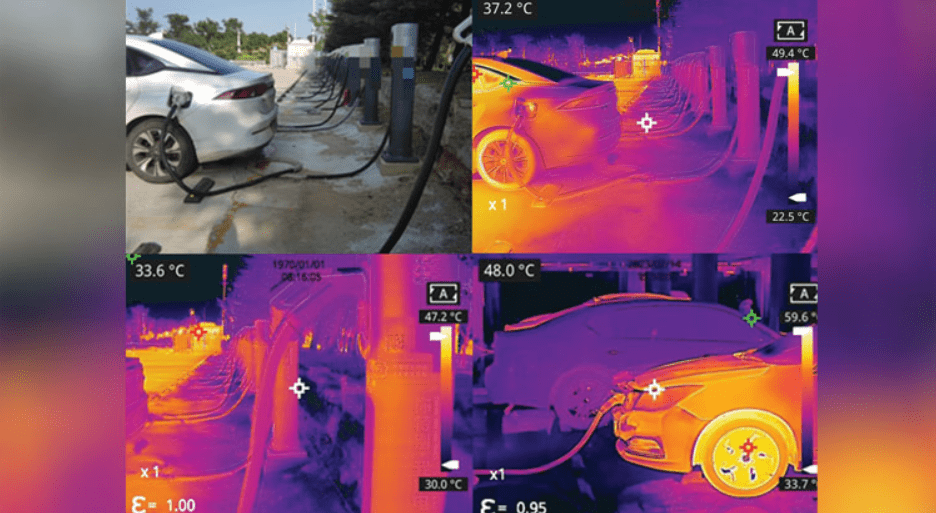

Thermal safety standards are crucial for maintaining optimal battery temperatures, preventing thermal runaway, and ensuring the longevity and safety of batteries.

IEC 62660-2 defines performance and testing standards for lithium-ion cells, emphasizing the need for effective thermal management. This ensures that the BMS can monitor and control battery temperature effectively.

ISO 18243 outlines safety standards for lithium-ion batteries, focusing on thermal and chemical hazards that may arise during battery operation, charging, or failure.

Battery temperature management is crucial to avoid overheating, which could lead to thermal runaway. The BMS must be capable of managing temperature extremes within safe limits.

Thermal testing ensures the BMS and battery are capable of performing under a wide range of temperature conditions without risking damage or failure.

Design requirements for thermal management include the incorporation of cooling systems, heat sinks, and temperature sensors to prevent the battery from reaching unsafe temperatures.

By following these standards, BMS manufacturers ensure that their systems can safely regulate temperature, thereby preventing overheating or cooling failures that could lead to significant hazards such as fires or explosions.

04. Battery-Specific Standards

Battery-specific standards address the design, testing, and safety requirements of battery systems, which directly influence the functionality and safety of the BMS.

UN 38.3 governs the transport of lithium batteries and mandates specific safety tests to ensure safe handling during shipping. The BMS must comply with these standards to prevent hazardous incidents during transport.

ISO 12405 specifies test requirements for lithium-ion battery systems used in EVs, detailing how the BMS should operate under various conditions such as temperature fluctuations and charging cycles.

SAE J2464 sets standards for abuse testing, including thermal, electrical, and mechanical abuse. This ensures that the BMS can detect and respond to abusive conditions, preventing catastrophic failures.

Cell protection mechanisms include overcharge, over-discharge, and temperature monitoring, which are integrated into the BMS design to safeguard against battery failure.

Performance under extreme conditions is also tested under these standards to ensure the BMS can function properly, even in challenging environments like deep discharges or rapid charging.

These standards are essential for ensuring that the BMS can manage and monitor battery safety effectively, ensuring the system’s longevity and minimizing the risks associated with battery failures in electric vehicles.

05. Cybersecurity Standards

As BMS systems increasingly integrate with vehicle control systems and IoT, ensuring their cybersecurity is paramount to prevent malicious attacks that could compromise battery safety.

ISO/SAE 21434 is a key standard for cybersecurity in road vehicles, focusing on risk management for electronic and electrical systems, including BMS. It defines processes for identifying and mitigating cyber threats.

Cybersecurity threat modeling is a key aspect, identifying potential attack vectors and ensuring the BMS can defend against unauthorized access or tampering.

Encryption and data protection are essential to safeguard communication between the BMS and other vehicle control systems, preventing data breaches and system compromises.

Regular software updates are necessary to patch vulnerabilities, ensuring the BMS can remain secure over its lifecycle.

Testing and validation ensure that cybersecurity measures are robust and can handle evolving threats, such as hacking or malware targeting critical systems like the BMS.

The integration of these standards in the design and operation of BMS helps to protect sensitive vehicle and battery data, ensuring that external threats do not disrupt the system’s safety functions, potentially leading to dangerous outcomes.

06. Environmental and Reliability Standards

Environmental and reliability standards ensure that the BMS operates effectively under harsh environmental conditions, ensuring long-term reliability and performance in diverse operating environments.

ISO 16750 addresses environmental conditions such as vibration, temperature extremes, and humidity that electrical/electronic equipment like BMS may encounter in vehicles. It provides testing requirements to ensure durability.

IEC 60068 defines environmental testing methods for electronic systems, ensuring the BMS can withstand environmental challenges and continue to operate safely and effectively.

Thermal cycling tests help determine if the BMS can handle the effects of temperature fluctuations without failure.

Shock and vibration tests ensure that the BMS can withstand the rough conditions encountered in vehicles, such as during bumpy drives or sudden impacts.

Long-term reliability is validated by subjecting the BMS to continuous operation tests under extreme conditions, ensuring it continues to function as expected throughout the vehicle’s lifecycle.

Adherence to these standards ensures that the BMS is not only capable of operating safely in a variety of conditions but can also offer reliable performance over the long term, minimizing the likelihood of failures.

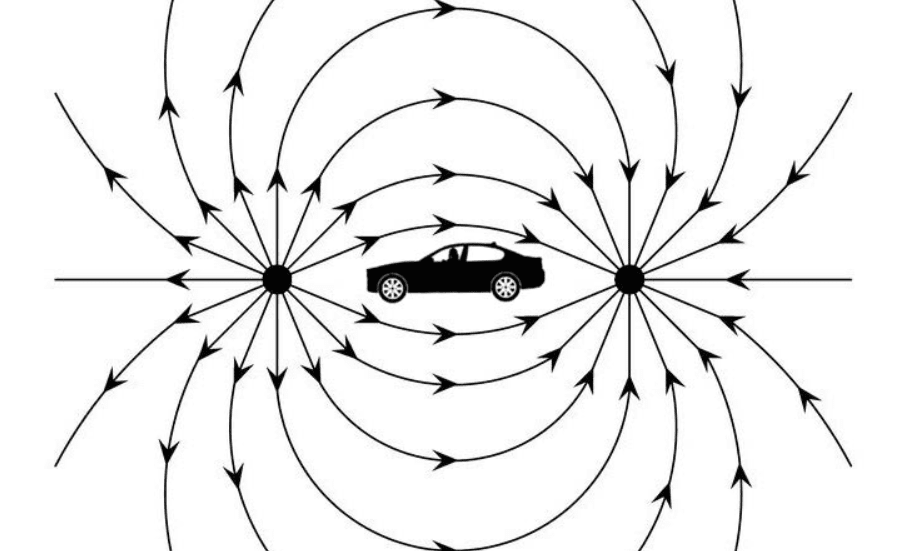

07. Electromagnetic Compatibility (EMC) Standards

Electromagnetic compatibility (EMC) standards ensure that the BMS does not interfere with other vehicle systems and that it can function properly despite external electromagnetic noise.

ISO 7637 outlines EMC standards for road vehicles, focusing on conducted transients. It ensures that the BMS can handle electrical noise and spikes without malfunctioning.

CISPR 25 sets the EMC requirements for automotive electronics, including BMS. It defines limits for electromagnetic emissions and immunity, ensuring that the BMS does not interfere with other electronic systems.

Shielding and filtering techniques are used in BMS design to minimize electromagnetic interference (EMI) and ensure compliance with these standards.

Grounding and proper circuit layout are essential to reduce the risk of electrical noise affecting the BMS.

Testing for EMC performance ensures that the BMS can operate without interference from other systems like the vehicle’s infotainment or safety systems.

By meeting these EMC standards, the BMS will function without causing harmful electromagnetic interference, contributing to the overall safety and reliability of the vehicle’s electrical systems.

08. Standards for Hazardous Materials

Hazardous material standards regulate the handling and containment of dangerous substances within batteries, ensuring the safety of both users and the environment.

IEC 62485 provides safety requirements for the installation and containment of hazardous materials in battery systems, ensuring the safe handling of potentially dangerous chemicals within the BMS.

ISO 14100 addresses the safe handling and management of lithium-ion batteries, specifically focusing on chemical safety and the potential risks posed by hazardous substances in the battery.

Chemical containment systems must be incorporated into the BMS to prevent leaks or spills of hazardous materials such as lithium or electrolyte.

Safety protocols include protective measures to ensure safe battery disposal, recycling, and transportation to minimize environmental impact.

Training and certification for personnel handling these batteries ensure they are well-prepared to manage hazardous materials safely.

These standards help reduce the risks associated with hazardous materials, ensuring the safe use, storage, and disposal of batteries used in electric vehicles. Compliance is crucial to prevent chemical exposure or environmental contamination.

This was about “Safety Standards For Battery Management (BMS)“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?

- Advanced Driver Assistance Systems (ADAS): How To Become An Expert In This Growing Field