Comparing Embedded Coder, Simulink Coder, And MATLAB Coder In Automotive Applications

Hello guys, welcome back to our blog. Here in this article, I will discuss the difference between an embedded coder, Simulink coder, and MATLAB coder in Automotive applications, and the purpose of each coder.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Every Automotive Engineer Must Have Expertise In These Domains

- Essential Tools For Embedded System Development And Testing

- Advantages Of Digital Twins In Automotive Manufacturing And Vehicle Development

Comparing Embedded Coder, Simulink Coder, And MATLAB Coder

With the increasing complexity of automotive systems, software development has become a crucial aspect of modern vehicle design. MATLAB, Simulink, and their associated coders provide powerful tools for developing, simulating, and deploying embedded software for automotive applications. Among these tools, Embedded Coder, Simulink Coder, and MATLAB Coder are widely used for automatic code generation. This article provides an in-depth comparison of these coders, focusing on their applications, strengths, limitations, and suitability for various automotive scenarios.

Overview of MATLAB, Simulink, and Their Coders

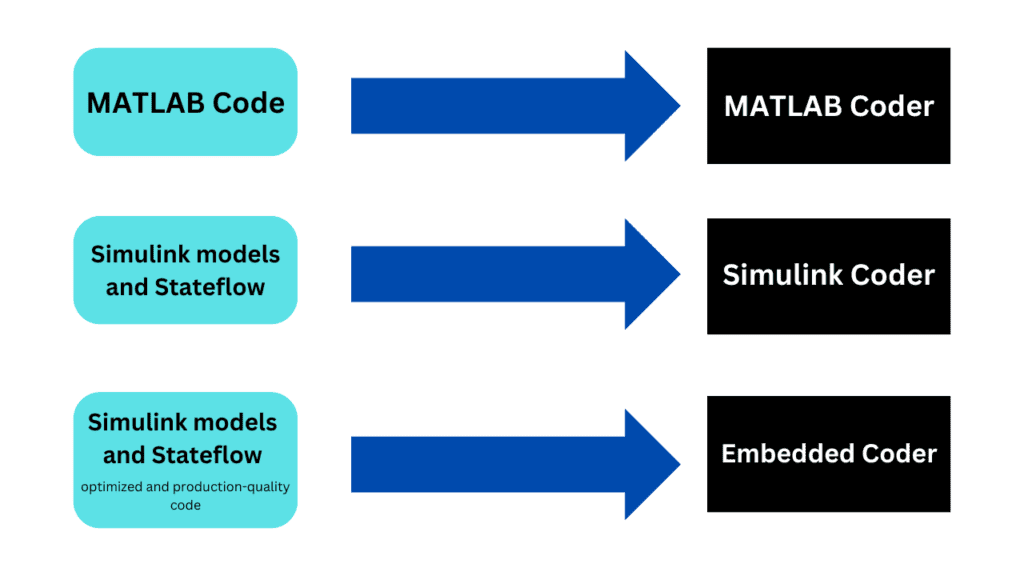

MATLAB Coder:

MATLAB Coder generates C and C++ code from MATLAB code, enabling its deployment on embedded systems. It is suitable for algorithm development and rapid prototyping.

Simulink Coder:

Simulink Coder generates C and C++ code from Simulink models and Stateflow charts. It is widely used in model-based design (MBD) for automotive applications, allowing engineers to integrate simulation models into real-time systems.

Embedded Coder:

Embedded Coder extends Simulink Coder by providing optimized and production-quality code for embedded systems. It is designed to meet stringent automotive standards, such as MISRA-C and AUTOSAR, making it the preferred choice for automotive applications.

Key Comparisons

| Feature | MATLAB Coder | Simulink Coder | Embedded Coder |

| Input | MATLAB scripts | Simulink models, Stateflow charts | Simulink models, Stateflow charts |

| Output | C/C++ code | C/C++ code | Optimized embedded C/C++ code |

| Optimization | Limited | Moderate | High (Memory, Execution Speed) |

| Embedded System Support | Basic | Moderate | Advanced (MISRA, AUTOSAR, Processor-Specific Optimization) |

| Automotive Standard Compliance | No | Partial | Full (ISO 26262, MISRA-C, AUTOSAR) |

| Use Case | Algorithm prototyping | Model-based design | Production-grade embedded software |

01. Code Optimization

- MATLAB Coder: Generates readable C code but lacks deep optimization.

- Simulink Coder: Provides moderate optimization by leveraging model configurations.

- Embedded Coder: Generates highly optimized code with low memory footprint and improved execution speed.

02. Embedded System Support

- MATLAB Coder: Suitable for basic embedded applications but lacks processor-specific optimization.

- Simulink Coder: Supports embedded deployment but lacks compliance with stringent automotive standards.

- Embedded Coder: Includes advanced features like fixed-point conversion, memory optimization, and AUTOSAR compliance.

03. Compliance with Automotive Standards

- MATLAB Coder: Does not comply with automotive coding standards.

- Simulink Coder: Partially supports standards like MISRA but is not tailored for full compliance.

- Embedded Coder: Fully supports ISO 26262, MISRA-C, and AUTOSAR, making it ideal for safety-critical automotive applications.

Use Cases in Automotive Applications

MATLAB Coder

- Rapid prototyping of control algorithms.

- Developing mathematical models and simulations.

- Implementing basic embedded system applications.

Simulink Coder

- Model-based design and simulation of automotive control systems.

- Hardware-in-the-loop (HIL) testing.

- Generating code for real-time embedded applications.

Embedded Coder

- Developing production-grade automotive ECUs.

- Generating highly optimized code for powertrain, ADAS, and safety systems.

- Supporting AUTOSAR-compliant software development.

Advantages and Disadvantages

01. MATLAB Coder

Pros:

- Easy to use for MATLAB users.

- Supports a wide range of algorithms.

- Useful for rapid prototyping.

Cons:

- Not optimized for real-time automotive applications.

- Limited hardware support.

- No compliance with automotive safety standards.

02. Simulink Coder

Pros:

- Facilitates model-based design.

- Supports real-time simulation and testing.

- Good integration with embedded systems.

Cons:

- The code is not highly optimized for production use.

- Partial compliance with automotive standards.

03. Embedded Coder

Pros:

- Highly optimized code for embedded applications.

- Compliance with automotive safety standards.

- Supports AUTOSAR and fixed-point conversion.

Cons:

- Steeper learning curve.

- Higher computational requirements.

Conclusion

Choosing the right coder depends on the specific requirements of the automotive application. MATLAB Coder is best for algorithm development and rapid prototyping, Simulink Coder excels in model-based design, and Embedded Coder is ideal for production-quality embedded software. By understanding their differences, automotive engineers can make informed decisions to optimize their development workflow.

This was about “Comparing Embedded Coder, Simulink Coder, And MATLAB Coder In Automotive Applications”. Thank you for reading.

Also, read:

- Testing Techniques For Test Case Writing in the Automotive Domain

- Different Storage Classes In MATLAB Simulink

- Mini Project / Hands-on Demo for Software-Defined Vehicles (SDVs): Part 08

- Challenges And Opportunities In Software Defined Vehicles (SDVs): Part 07

- Case Study: Real-World Software-Defined Vehicle Examples: Part 06

- Software-Defined Vehicles Development Lifecycle: Part 05

- Software-Defined Vehicles Enabling Technologies: Part 04

- Core Software Layers In Software Defined Vehicles: Part 03