Types Of Errors Found In MiL, SiL, And HiL Testing

Hello guys, welcome back to our blog. In this article, we will discuss the types of errors found in MiL, SiL, and HiL testing.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Automotive Ethernet: The Future Of In-Vehicle Communication

- Top 100 C Coding-based “Predict The Output” Interview Questions With Explanations

- Top 100 Advanced Level ADAS Interview Questions With Answers

Errors Found In MiL, SiL, And HiL Testing

In the modern automotive development process, ensuring the reliability, safety, and performance of embedded systems is paramount. Model-based design (MBD) plays a pivotal role in achieving these objectives through iterative testing and validation phases known as Model-in-the-Loop (MiL), Software-in-the-Loop (SiL), and Hardware-in-the-Loop (HiL). Each of these stages helps detect specific classes of errors that could compromise the vehicle’s safety or performance. In this article, we will explore the kinds of errors uncovered during MiL, SiL, and HiL testing, providing a comprehensive guide for automotive software engineers, validation teams, and system integrators.

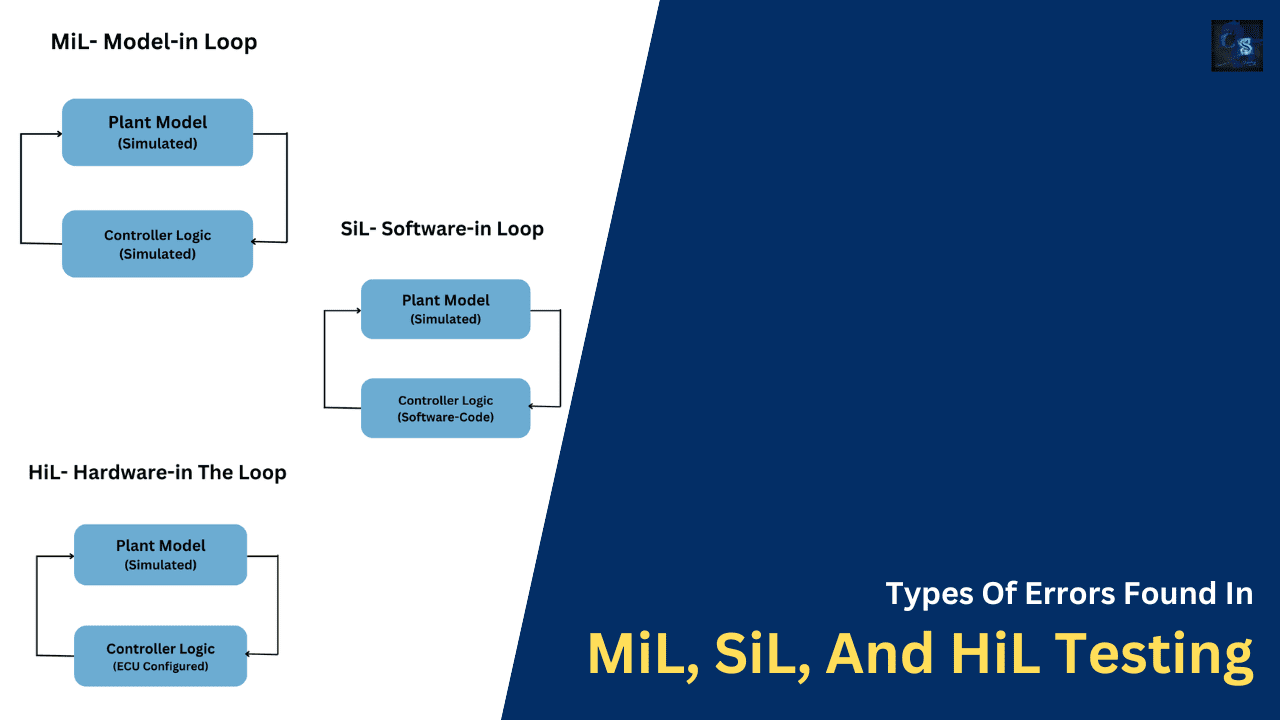

Model-in-the-Loop (MiL) Testing

MiL is the initial simulation phase where the control algorithms are tested using models, typically in environments like MATLAB/Simulink. The goal is to validate the system’s logic, mathematical formulation, and dynamic behavior before software implementation.

Types of Errors in MiL (Model-in Loop)

a) Logical Errors

- Misimplementation of control logic

- Incorrect transition conditions in Stateflow charts

- Faulty use of logic gates

b) Modeling Errors

- Incorrect mathematical representation

- Feedback loops without delays causing algebraic loops

- Usage of continuous blocks in fixed-step simulations

c) Interface Errors

- Mismatch in input/output signal dimensions

- Incorrect port connections

d) Parameterization Errors

- Wrong parameter values for gains, constants

- Unit mismatches (e.g., using m/s instead of km/h)

e) Numerical Errors

- Division by zero

- Overflow or underflow conditions

- Poor conditioning of mathematical operations

f) Algorithm Design Issues

- Oversimplified or overly complex models

- Poor scalability of models

- Lack of modularity, making debugging difficult

g) Requirement Mismatch

- Incomplete traceability from requirements to model

- Uncovered test scenarios

Benefits of MiL Error Detection

- Early-stage debugging reduces downstream costs

- Allows easy changes before software generation

- Ensures algorithms align with functional requirements

Software-in-the-loop (SiL) Testing

In SiL, the model is converted into C code and executed in a simulation environment to ensure the generated code maintains the same behavior as the original model. It bridges the gap between theoretical models and practical implementation.

Types of Errors in SiL

a) Code Generation Errors

- Loss of precision due to data type conversions

- Misinterpretation of algorithm logic in generated code

b) Data Type Mismatch

- Float to integer conversions causing truncation

- Incorrect fixed-point scaling

c) Functionality Errors

- Differences in execution results between model and generated code

- Behavioral deviations due to compiler optimizations

d) Memory Management Errors

- Stack overflow

- Heap misallocation

- Static vs dynamic memory usage mismatch

e) Compiler Issues

- Compiler-specific warnings or errors

- Portability issues across compilers

f) Timing Issues

- Task overruns due to inefficient code

- Incorrect scheduling in multitask environments

g) Interface Errors

- Incorrect I/O definitions in the code

- Communication stack errors during message simulation

Benefits of SiL Error Detection

- Ensures code fidelity with the model

- Enables tuning for optimization before actual deployment

- Catches early software-level bugs without hardware involvement

Hardware-in-the-loop (HiL) Testing

HiL simulates real-world operating conditions by connecting the ECU to a real-time system that mimics vehicle sensors and actuators. It provides the closest possible environment to in-vehicle testing.

Types of Errors in HiL

a) Real-Time Execution Errors

- Missed deadlines in real-time task execution

- Latency in sensor response simulation

b) Hardware Integration Issues

- Incorrect ECU pin mapping

- Poor power supply or grounding

- Short circuits and connector faults

c) Communication Interface Errors

- CAN/LIN/FlexRay misconfigurations

- Protocol timing violations

- Bus load issues

d) Sensor/Actuator Simulation Issues

- Incorrect signal conditioning

- Sensor signal drift or noise simulation errors

e) DTC Logging and Diagnostic Issues

- Incorrect DTC storage and retrieval

- Failure in executing UDS services like Read/Write Data By Identifier

f) Environmental Condition Testing Errors

- Failure under simulated voltage variations (e.g., cranking tests)

- Thermal behavior mismatches not captured

g) Timing and Synchronization Errors

- Delay in ECU and HiL tool communication

- Clock drift issues

h) Safety Feature Validation Failures

- Failsafe or degraded mode not triggered properly

- Emergency braking or fallback strategies not activated

Benefits of HiL Error Detection

- Verifies complete system integration

- Tests edge-case scenarios difficult to reproduce in-vehicle

- Reduces need for expensive and risky road testing

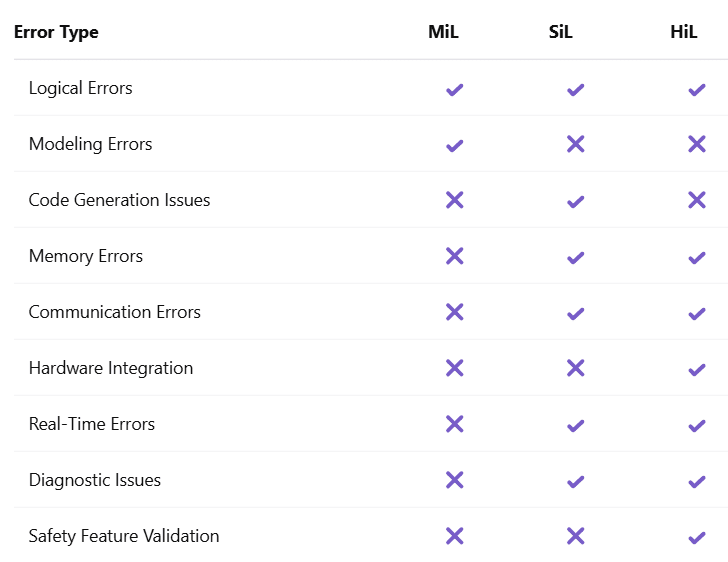

Comparison Table: Errors in MiL, SiL, and HiL

Best Practices for Error Mitigation Across MiL, SiL, and HiL

- Maintain strict version control for models and code

- Implement continuous integration pipelines for MiL/SiL/HiL

- Use requirement-based testing

- Perform static and dynamic analysis

- Use model and code coverage tools

- Create automated test suites with traceability to requirements

- Maintain consistent interface definitions across all phases

- Document errors and fixes with traceability

Conclusion: The progressive testing approach through MiL, SiL, and HiL is foundational in modern automotive embedded system development. Each phase plays a crucial role in uncovering distinct types of errors. A deep understanding of these errors enables developers and testers to implement effective mitigation strategies, ensuring the delivery of high-quality, reliable, and safe automotive systems. As automotive systems grow more complex with the advent of ADAS, electrification, and autonomous vehicles, robust validation across these testing levels is more critical than ever.

By identifying errors early and across multiple simulation environments, teams can reduce time-to-market, lower development costs, and, most importantly, build safer vehicles for the road.

This was about “Types Of Errors Found In MiL, SiL, And HiL Testing“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?

- Advanced Driver Assistance Systems (ADAS): How To Become An Expert In This Growing Field