Hello guys, welcome back to our blog. Here in this article, we will discuss the advantages of digital twins in automotive manufacturing and vehicle development.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Cloud-Based HiL Testing: Benefits And Challenges

- List Of Automotive Companies: OEMs, Product-Based, And Service-Based Firms

- A Complete Guide To FlexRay Automotive Protocol

Advantages Of Digital Twins In Automotive

The automotive industry is undergoing a digital transformation, leveraging advanced technologies to improve manufacturing efficiency, vehicle design, and customer experiences. One such innovation that has gained widespread adoption is the concept of digital twins. A digital twin is a virtual representation of a physical asset, process, or system that allows real-time monitoring, analysis, and simulation.

In the automotive sector, digital twins are revolutionizing manufacturing and vehicle development by enabling predictive maintenance, enhancing design precision, and optimizing performance. This article explores the numerous advantages of digital twins in automotive manufacturing and vehicle development.

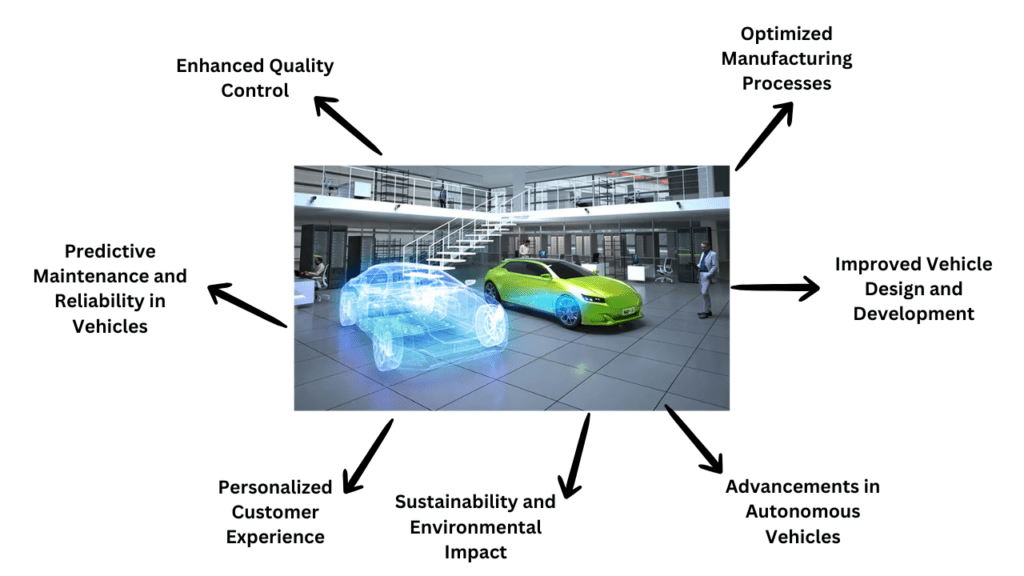

01. Improved Vehicle Design and Development

Digital twins play a crucial role in the design and development phase of vehicles. They allow automotive engineers to create detailed virtual models of vehicles and components, enabling:

Enhanced Prototyping: Traditional prototyping is time-consuming and expensive. With digital twins, manufacturers can simulate different designs and configurations before producing physical prototypes, significantly reducing costs and development time.

Realistic Simulations: Engineers can test aerodynamics, crashworthiness, and other performance factors using digital simulations, ensuring the vehicle meets safety and efficiency standards.

Rapid Iteration: Design flaws can be identified and rectified early in the development process, leading to faster iterations and better final products.

02. Optimized Manufacturing Processes

In automotive manufacturing, digital twins provide a digital replica of production lines, machinery, and assembly processes. The benefits include:

Predictive Maintenance: Sensors embedded in manufacturing equipment collect data in real time, allowing predictive analytics to forecast potential failures before they occur, minimizing downtime and maintenance costs.

Process Optimization: Digital twins enable manufacturers to analyze production workflows and identify inefficiencies, ensuring optimal resource allocation and productivity.

Supply Chain Management: By integrating digital twins with supply chain data, manufacturers can anticipate disruptions, manage inventory efficiently, and reduce material waste.

03. Enhanced Quality Control

Digital twins help maintain high-quality standards in automotive manufacturing by enabling:

Defect Detection: Machine learning algorithms analyze sensor data to detect defects and anomalies in real-time, ensuring only high-quality components reach the production line.

Automated Testing: Virtual simulations of manufacturing processes allow continuous testing of products and machinery, leading to fewer errors and improved quality assurance.

Root Cause Analysis: When defects arise, digital twins provide detailed insights into their root causes, allowing manufacturers to implement corrective actions promptly.

04. Predictive Maintenance and Reliability in Vehicles

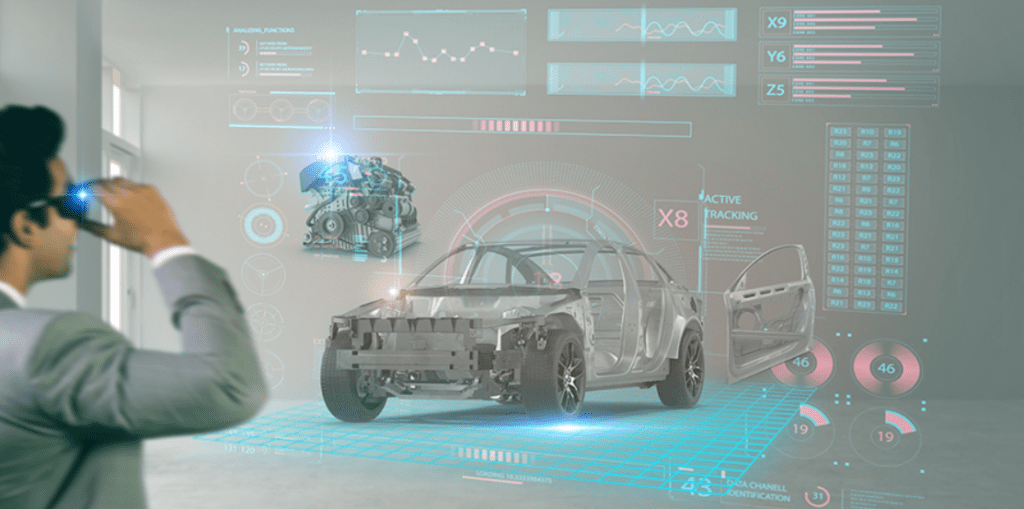

For automotive manufacturers and fleet operators, digital twins offer significant advantages in predictive maintenance:

Real-Time Monitoring: Vehicles equipped with IoT sensors can transmit data to digital twins, allowing remote monitoring of critical components such as engines, brakes, and battery systems.

Failure Prediction: AI-driven analytics detect patterns in vehicle performance data, predicting potential failures before they occur, reducing unexpected breakdowns and repair costs.

Extended Vehicle Lifespan: By optimizing maintenance schedules and ensuring timely interventions, digital twins contribute to increased vehicle longevity and reliability.

05. Personalized Customer Experience

Automotive manufacturers are leveraging digital twins to enhance customer experience and satisfaction:

Customized Vehicle Configurations: Digital twins allow customers to visualize and personalize their vehicles with different configurations, such as color, interior features, and performance specifications.

Usage-Based Insurance Models: Insurance companies can use digital twin data to offer personalized insurance plans based on driving behavior and vehicle condition.

Remote Diagnostics: Car owners can receive real-time updates on vehicle health, reducing the need for frequent service center visits and improving overall user experience.

06. Advancements in Autonomous Vehicles

Digital twins play a critical role in the development and deployment of autonomous vehicles:

Training AI Models: Autonomous vehicle systems require extensive testing and validation. Digital twins provide a safe virtual environment to train AI models under various driving conditions.

Simulating Traffic Scenarios: Developers can simulate real-world traffic conditions, weather changes, and road obstacles, ensuring self-driving algorithms perform reliably.

Regulatory Compliance: Virtual testing of autonomous vehicles helps meet regulatory safety standards before real-world deployment.

07. Sustainability and Environmental Impact

The adoption of digital twins contributes to sustainability efforts in the automotive industry:

Reducing Material Waste: Virtual simulations minimize the need for physical prototypes, reducing material consumption and waste.

Energy Efficiency: Digital twins help optimize energy usage in both manufacturing plants and vehicles, lowering carbon footprints.

Lifecycle Management: By analyzing vehicle performance data, manufacturers can design longer-lasting, energy-efficient models with reduced environmental impact.

Conclusion

Digital twins are revolutionizing the automotive industry by transforming how vehicles are designed, manufactured, and maintained. From enhancing product quality and optimizing manufacturing processes to improving vehicle reliability and enabling autonomous driving, digital twins offer a wide range of benefits.

As technology continues to evolve, digital twins will play an even greater role in shaping the future of automotive innovation, ensuring efficiency, sustainability, and superior customer experiences. Embracing this technology is essential for automakers to stay competitive and drive the industry toward a smarter, more connected future.

This was about “Advantages Of Digital Twins In Automotive Manufacturing And Vehicle Development“. Thank you for reading.

Also, read:

- “Mother of All Deals”: How The EU–India Free Trade Agreement Can Reshape India’s Economic Future

- 10 Free ADAS Projects With Source Code And Documentation – Learn & Build Today

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 2026 Hackathons That Can Change Your Tech Career Forever

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway