Hello guys, welcome back to my blog. In this article, I will discuss automotive-grade microcontrollers Vs general-purpose MCUs, what sets them apart, and applications of automotive grade MCUs.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Upcoming Technologies To Learn In The Automotive Industry To Get High-Paying Jobs

- How Is DoIP Different From CAN-based Diagnostics?

- Difference Between Domain And Zonal Architecture in Automotive: A Complete Guide

Automotive-Grade Microcontrollers

In today’s automotive industry, microcontrollers (MCUs) are at the heart of nearly every critical function—from controlling engines and transmissions to enabling advanced driver-assistance systems (ADAS), infotainment, and battery management. However, not all microcontrollers are created equal. The automotive environment demands components that are significantly more robust, reliable, and long-lasting than their general-purpose counterparts.

In this article, we’ll take an in-depth look at automotive-grade microcontrollers, explore how they differ from general-purpose MCUs, and understand why these differences matter in safety-critical environments like automobiles.

What Is a Microcontroller?

A microcontroller is a compact integrated circuit designed to govern a specific operation in an embedded system. It usually includes:

- A CPU (central processing unit)

- Memory (RAM and ROM/Flash)

- Peripherals (e.g., timers, UART, SPI, I2C, ADCs, etc.)

MCUs are widely used in home appliances, medical equipment, industrial machines, and especially vehicles.

What Are Automotive-Grade Microcontrollers?

Automotive-grade microcontrollers are specially designed MCUs tailored to meet the rigorous requirements of automotive applications. These requirements are dictated by functional safety, extreme environmental conditions, reliability, and compliance with industry standards.

Key uses include:

- Engine control units (ECUs)

- Advanced driver-assistance systems (ADAS)

- Infotainment systems

- Electric vehicle (EV) battery management

- Chassis and braking systems

Key Standards Defining Automotive-Grade MCUs

Automotive MCUs must comply with a host of standards that ensure safety and performance, including:

? ISO 26262 (Functional Safety): Defines the requirements for functional safety in road vehicles. It introduces ASIL (Automotive Safety Integrity Level) classifications ranging from A (lowest) to D (highest), and MCUs must meet ASIL requirements based on their application.

?️ AEC-Q100: This is a qualification standard for ICs used in automotive environments. It categorizes devices based on operating temperature and stress testing, such as:

- Grade 0: –40°C to +150°C

- Grade 1: –40°C to +125°C

- Grade 2: –40°C to +105°C

? ASIL Ready Design Tools: Automotive MCUs often come with toolchains that are certified or qualified under ISO 26262 to support safety-critical design.

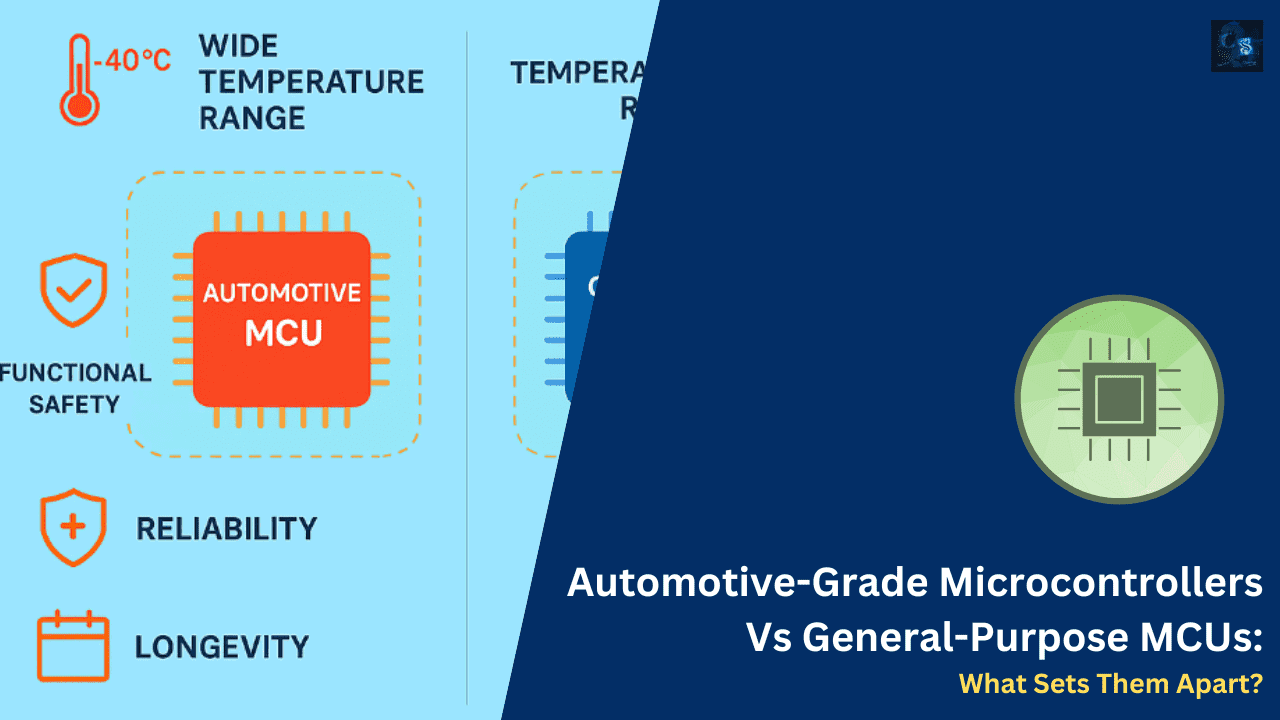

Core Differences: Automotive Vs General-Purpose MCUs

Let’s break down the key differences between automotive-grade MCUs and general-purpose MCUs.

| Feature | Automotive-Grade MCU | General-Purpose MCU |

| Temperature Range | –40°C to +150°C | 0°C to +85°C (typically) |

| Functional Safety | ISO 26262 compliance, ASIL levels | Not usually safety-certified |

| Reliability | High EMI/EMC tolerance, low failure rate (FIT) | Basic reliability for consumer use |

| Longevity | 10–15 years support and availability | 10–15 years of support and availability |

| Test and Validation | Burn-in testing, AEC-Q100, full traceability | Standard manufacturing tests only |

| Redundancy & Diagnostics | Dual-core lockstep, ECC memory, BIST | Rarely supported |

| Development Ecosystem | Safety-certified tools, AUTOSAR support | Generic IDEs and debuggers |

| Quality Standards | PPAP, APQP, IATF 16949 | None or ISO 9001 |

| Packaging | Designed for harsh environments (vibration, moisture) | Standard plastic packaging |

Why Are These Differences Crucial?

? Safety-Critical Applications: In applications like braking, steering, or airbags, failure is not an option. Automotive MCUs are designed to detect faults, perform self-checks, and fail safely when necessary.

? Long Lifecycle: Automotive products are expected to be in use for over a decade. MCU vendors must guarantee long-term supply, firmware update support, and quality consistency.

? Environmental Toughness: General-purpose MCUs are not built for the automotive environment, which is full of:

- Temperature extremes

- Vibration and mechanical stress

- Electromagnetic interference

Automotive-grade MCUs are robust enough to withstand all of the above.

Features Unique to Automotive MCUs

? Redundancy (Dual Core Lockstep): To support ASIL-D levels of safety, some MCUs use two cores executing the same instructions simultaneously. A mismatch triggers a safe state.

? ECC Memory: Error Correction Code (ECC) protects both Flash and RAM memory, crucial for avoiding random bit flips caused by radiation.

? Built-In Self-Test (BIST): Startup and runtime checks ensure that critical MCU components (CPU, memory, peripherals) are functioning correctly.

? CAN, LIN, FlexRay, and Ethernet Support: Automotive MCUs often have multiple automotive-specific communication interfaces built in, optimized for real-time and fault-tolerant data transfer.

? AUTOSAR Compatibility: Most automotive MCUs are designed to work seamlessly with AUTOSAR (Automotive Open System Architecture) software stacks.

Applications of Automotive-Grade MCUs

| System | Function |

| Powertrain | Engine and transmission control |

| Chassis & Safety | ABS, ESP, electric steering |

| Body Electronics | Window lifters, climate control, lighting |

| Infotainment | Audio/video, display, voice recognition |

| ADAS | Sensor fusion, radar/lidar processing |

| EV Systems | Battery management, charging, motor control |

Leading Automotive MCU Families

? NXP S32 Series: Highly scalable family for ADAS, body, powertrain, and radar. Supports ISO 26262 up to ASIL D.

? Infineon AURIX™: Designed for safety and real-time applications. Triple-core architecture with lockstep and high-speed comms.

? Renesas RH850: Wide range for body, powertrain, and ADAS. Features ECC, CAN-FD, and safety mechanisms.

? STMicroelectronics SPC5 Series: Powerful automotive MCUs with support for FlexRay, CAN, and Ethernet. ISO 26262 qualified.

? Texas Instruments Hercules: MCUs with lockstep architecture and comprehensive diagnostics for functional safety.

Challenges in Automotive MCU Development

Developers working with automotive MCUs face several hurdles:

⏳ Stringent Development Cycles: Designing for automotive safety standards like ISO 26262 significantly lengthens development time.

? Verification & Validation: Exhaustive testing—unit testing, HIL simulation, safety checks—makes the process complex and expensive.

⚙️ AUTOSAR Integration: Ensuring proper software architecture for interoperability and reusability across ECUs is challenging.

? Firmware Updates (OTA): Modern vehicles require secure, fail-safe over-the-air updates, adding another layer of complexity to MCU software.

The Future of Automotive MCUs

? Integration with AI and ML: MCUs are beginning to integrate AI accelerators to support intelligent decision-making in ADAS and autonomous vehicles.

? Shift to SoCs: The line between MCUs and SoCs is blurring as more functions are integrated into single-chip solutions.

? Electrification: As EVs rise, automotive MCUs are playing a critical role in BMS, inverter control, and power conversion.

? Enhanced Cybersecurity: Security modules are becoming mandatory for protection against ECU hacking and ensuring secure communication.

Conclusion

Automotive-grade microcontrollers are engineered to meet some of the strictest requirements in the embedded world. Their key strengths lie in reliability, safety compliance, environmental toughness, and long-term availability. While general-purpose MCUs may be suitable for everyday electronics, they fall short in the demanding environment of automotive systems.

For engineers and developers, understanding the critical differences is essential when designing or working with systems where human lives, safety, and mission-critical performance are on the line.

This was about “Automotive-Grade Microcontrollers“. Thank you for reading.

Also, read:

- “Mother of All Deals”: How The EU–India Free Trade Agreement Can Reshape India’s Economic Future

- 10 Free ADAS Projects With Source Code And Documentation – Learn & Build Today

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 2026 Hackathons That Can Change Your Tech Career Forever

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway