Automotive System Engineering From The ASPICE Perspective

Hello guys, welcome back to our blog. In this article, I will discuss automotive system engineering from the ASPICE perspective, the ASPICE V-Model, and system engineering.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- How to Perform Hardware-in-the-Loop (HiL) Testing with Simulink

- PREEvision: A Comprehensive Guide To Model-Based Automotive E/E Engineering

- Top 100 Automotive Companies And Their Career Portal Link

Automotive System Engineering From The ASPICE Perspective

Automotive System Engineering is a structured approach to designing, developing, and validating vehicle systems. It ensures that vehicles meet safety, performance, and compliance requirements. In recent years, ASPICE (Automotive Software Process Improvement and Capability dEtermination) has become the industry standard for defining best practices in system and software development.

This article explores Automotive System Engineering from an ASPICE perspective, covering its process framework, development methodologies, compliance requirements, and implementation strategies.

What is ASPICE?

ASPICE is a process assessment model developed for the automotive industry to improve software and system development processes. It defines structured capability levels that help organizations measure and enhance their engineering practices.

ASPICE Capability Levels:

- Level 0 (Incomplete Process) – No structured process exists.

- Level 1 (Performed Process) – Basic tasks are performed but lack standardization.

- Level 2 (Managed Process) – Defined processes exist with proper monitoring and control.

- Level 3 (Established Process) – The process is standardized across the organization.

- Level 4 (Predictable Process) – Quantitative analysis and data-driven decision-making occur.

- Level 5 (Innovating Process) – Continuous process optimization and innovation are implemented.

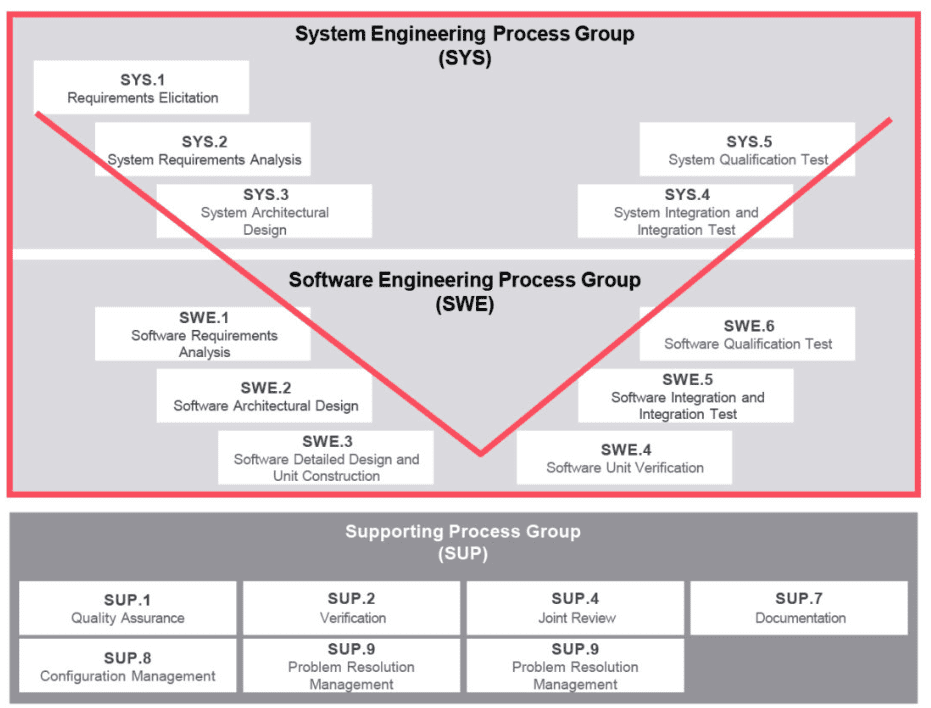

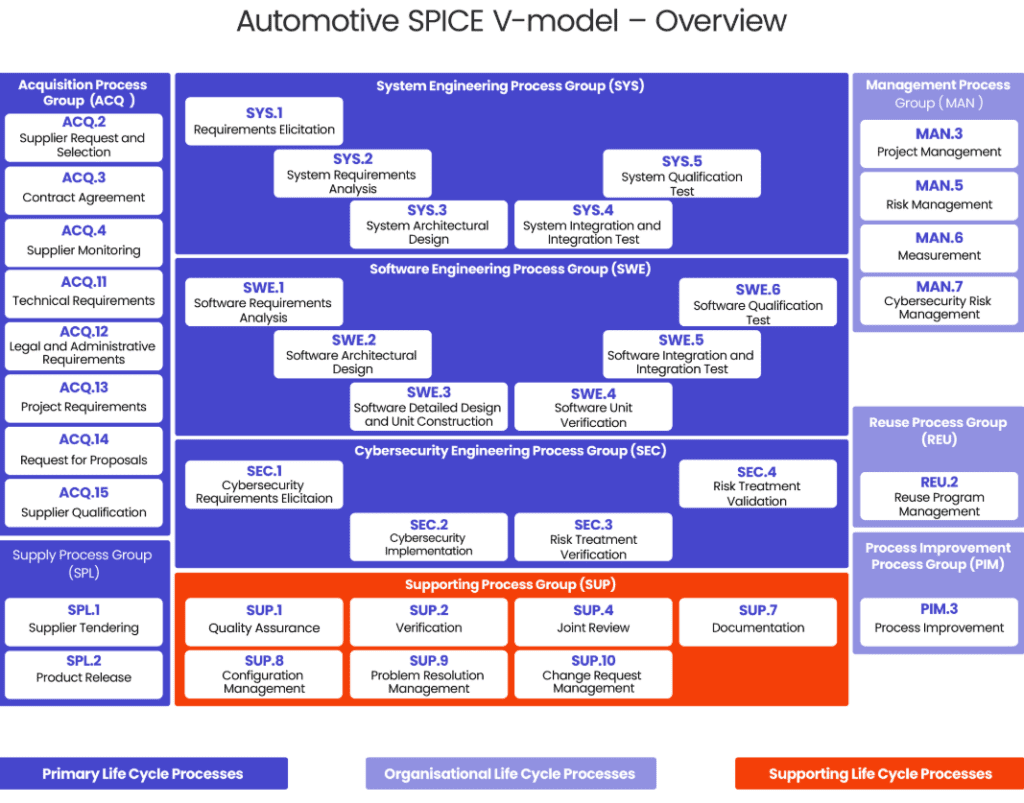

ASPICE V-Model and System Engineering

ASPICE aligns with the V-Model, a widely used systems engineering framework in automotive development. The V-Model divides development into two main parts:

01. Left Side (Development Phase)

a. System Requirements Analysis (SYS.1)

- Define vehicle-level functional and non-functional requirements.

- Ensure traceability between customer needs and system specifications.

b. System Architecture Design (SYS.2)

- Develop a system-level architecture.

- Identify key hardware and software components.

c. Software & Hardware Requirements (SWE.1 & HW.1)

- Decompose system requirements into software and hardware specifications.

- Define component interactions and interfaces.

d. Software & Hardware Design (SWE.2 & HW.2)

- Develop detailed software and hardware designs.

- Ensure compatibility with the overall system architecture.

02. Right Side (Verification & Validation)

a. Software Unit Testing (SWE.4)

- Perform low-level testing on individual software modules.

- Ensure compliance with coding guidelines and industry standards.

b. Software Integration & Testing (SWE.5)

- Integrate software modules and validate interactions.

- Conduct dynamic testing to detect defects.

c. System Integration & Testing (SYS.4)

- Combine hardware and software components for overall system validation.

- Verify functional safety requirements.

d. Vehicle Testing & Release (SYS.5)

- Conduct full vehicle validation.

- Perform regulatory compliance checks before market release.

ASPICE Process Groups Relevant to System Engineering

ASPICE defines Process Groups that standardize system engineering tasks:

01. System Development (SYS) Processes

- SYS.1 – System Requirements Analysis

- SYS.2 – System Architecture Design

- SYS.3 – System Integration & Testing

- SYS.4 – System Qualification Testing

02. Software Development (SWE) Processes

- SWE.1 – Software Requirements Analysis

- SWE.2 – Software Architecture Design

- SWE.3 – Software Detailed Design & Unit Construction

- SWE.4 – Software Unit Verification

- SWE.5 – Software Integration & Testing

- SWE.6 – Software Qualification Testing

03. Supporting Processes

- SUP.1 – Quality Assurance

- SUP.8 – Configuration Management

- SUP.9 – Problem Resolution Management

- SUP.10 – Change Management

ASPICE and Functional Safety (ISO 26262)

ASPICE focuses on process standardization, whereas ISO 26262 ensures functional safety in automotive systems. Both frameworks complement each other in ensuring:

- Hazard Analysis & Risk Assessment (HARA)

- Automotive Safety Integrity Level (ASIL) Classification (A, B, C, D)

- Safety Requirements Traceability

- Verification & Validation to Ensure Safe System Behavior

ASPICE Compliance and Assessment

To ensure ASPICE compliance, organizations must undergo Capability Level Assessments (CLA). These assessments focus on:

- Process Maturity Evaluation – How well processes adhere to ASPICE guidelines.

- Requirement Traceability – Ensuring all system requirements are linked to implementation.

- Change and Configuration Management – Managing software and system updates effectively.

- Defect Prevention & Continuous Improvement – Reducing failures through iterative process improvements.

ASPICE Assessment Levels

- Base Level Assessment – Evaluates compliance with ASPICE Level 1.

- Gap Analysis – Identifies weaknesses in process implementation.

- Formal Assessment – Determines official ASPICE certification level.

ASPICE Implementation in Automotive Projects

Steps to Achieve ASPICE Compliance

01. Define System Requirements Clearly

- Ensure completeness and alignment with customer needs.

- Use requirement management tools like DOORS and Polarion.

02. Develop Modular Architecture

- Use a component-based approach for reusability and maintainability.

- Follow industry best practices for software and hardware design.

03. Implement Process Documentation

- Maintain proper documentation for ASPICE audits.

- Use standard templates and process descriptions.

04. Ensure Early Verification & Validation

- Use HiL (Hardware-in-the-Loop) and SiL (Software-in-the-Loop) testing.

- Automate testing for continuous integration (CI/CD pipelines).

05. Automate Requirement Traceability

- Link requirements to test cases and verification reports.

- Use tools like JIRA and IBM RTC for issue tracking.

06. Conduct Regular Process Reviews & Audits

- Perform internal audits before external ASPICE assessments.

- Implement a corrective action plan for identified gaps.

ASPICE Compliance Tools

Several tools help in ASPICE process implementation and assessment:

- Requirement Management – IBM DOORS, Polarion

- Configuration Management – Git, SVN

- Defect Tracking – JIRA, IBM RTC

- Testing & Validation – CANoe, dSPACE, VectorCAST

Challenges in Implementing ASPICE

Despite its benefits, organizations face several challenges when implementing ASPICE:

- High Implementation Costs – Process changes require significant investment.

- Cultural Resistance – Engineering teams may resist adopting new structured processes.

- Lack of Expertise – ASPICE assessments require trained professionals.

- Process Overhead – Increased documentation and compliance requirements.

Solutions to Overcome Challenges:

- Training & Awareness – Conduct workshops on ASPICE best practices.

- Phased Implementation – Gradually introduce ASPICE-compliant processes.

- Automated Compliance Checks – Use software tools for process tracking and audits.

Conclusion

ASPICE provides a structured and standardized approach to automotive system engineering. It ensures that software and hardware development meet the highest quality, safety, and compliance standards. By adopting ASPICE methodologies, automotive companies can improve efficiency, reliability, and regulatory compliance while reducing development risks.

Key Takeaways:

- ASPICE improves process maturity and standardization.

- It aligns with the V-Model for structured development.

- ASPICE complements ISO 26262 for functional safety.

- Successful ASPICE implementation requires proper tools, training, and process automation.

As the automotive industry moves toward electrification and automation, ASPICE will remain a cornerstone for high-quality software and system development. 🚗💡

This was about “Automotive System Engineering From The ASPICE Perspective“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?