Designing An Automotive Test System For ECU Validation

Hello guys, welcome back to our blog. In this article, I will discuss designing an automotive test system for ECU validation, test system architecture, and hardware selection for ECU validation.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Top 30 Automotive-Specific ISO Standards Every Automotive Engineer Must Know

- Hazard Identification Techniques In Functional Safety (FuSa) ISO 26262

- Troubleshooting CAN Communication Failures In A Test Environment

Designing An Automotive Test System For ECU Validation

Electronic Control Units (ECUs) serve as the backbone of modern automotive systems, orchestrating critical functions such as engine performance, transmission control, safety features, and infotainment systems. As vehicles become more sophisticated with increased connectivity and automation, the need for rigorous ECU validation has never been greater.

ECU validation ensures that the unit meets functional, performance, and regulatory standards before deployment. Without proper testing, undetected faults in an ECU could lead to catastrophic failures, safety hazards, and expensive recalls. This article explores the design and implementation of a robust automotive test system for ECU validation. It delves into hardware and software selection, automation techniques, validation methodologies, industry standards, and best practices to ensure comprehensive and reliable ECU testing.

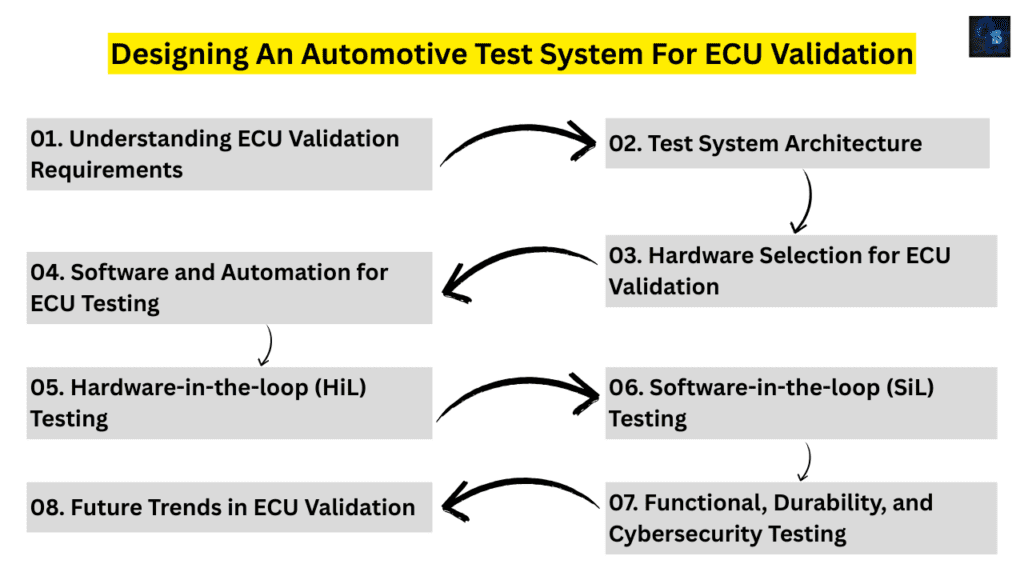

01. Understanding ECU Validation Requirements

1.1 Industry Standards and Regulations

Automotive ECUs must comply with various industry standards that define safety, reliability, and communication protocols. Some of the most widely recognized standards include:

ISO 26262: This functional safety standard outlines the lifecycle and safety requirements for automotive electrical and electronic systems. It mandates rigorous validation processes to minimize the risk of system failures.

ASPICE (Automotive SPICE): This framework assesses the maturity of software development processes in the automotive industry. It ensures that ECU software is developed and tested with consistent quality.

AUTOSAR: This open and standardized software architecture promotes reusability and scalability across automotive ECUs.

SAE J1939 and ISO 14229 (UDS Protocol): These protocols define the communication standards for vehicle networks, ensuring interoperability and diagnostics capability across different ECU modules.

1.2 Types of ECU Testing

ECU validation encompasses several types of testing, each focusing on different aspects of performance and reliability:

- Functional Testing: Ensures that the ECU operates according to its intended function under normal conditions.

- Performance Testing: Evaluates response times, processing power, and communication efficiency under various loads.

- Durability Testing: Subjects the ECU to extended operational cycles to assess its long-term reliability.

- Cybersecurity Testing: Identifies vulnerabilities that could be exploited by attackers, ensuring robust protection mechanisms are in place.

- Regression Testing: Verifies that new software updates do not introduce unintended issues in previously validated functionalities.

02. Test System Architecture

An automotive test system for ECU validation consists of multiple hardware and software components working together to replicate real-world conditions. The primary components include:

2.1 Test Bench Setup

The test bench mimics an actual vehicle environment, providing a controlled setup for validating ECU functionality. It typically consists of:

- Power Supply Units: Deliver stable voltage and current to the ECU.

- Sensor and Actuator Simulators: Mimic real-world vehicle signals to interact with the ECU.

- Environmental Chambers: Simulate extreme temperatures, humidity, and vibration conditions.

2.2 Communication Interfaces

ECUs communicate with other vehicle components using various network protocols. A test system must support:

- Controller Area Network (CAN): The most widely used communication protocol in automotive ECUs.

- Local Interconnect Network (LIN): A cost-effective protocol used for non-critical applications.

- FlexRay: A high-speed network for advanced driver assistance systems (ADAS).

- Ethernet: Enables high-speed data transfer in modern connected vehicles.

2.3 Data Acquisition Systems

A robust data acquisition system is essential for monitoring, recording, and analyzing ECU performance metrics in real time. Key components include:

- High-Speed Data Loggers: Capture ECU communication and sensor data.

- Signal Conditioners: Ensure accurate readings from sensors and actuators.

- Real-Time Monitoring Software: Visualizes and analyzes test results.

03. Hardware Selection for ECU Validation

Choosing the right hardware for ECU validation is crucial to ensuring accurate and reliable test results. The key components include:

3.1 Microcontrollers and Processors

The test system should match the processing power and architecture of the ECU being validated. Factors to consider include:

- Clock speed and processing capabilities

- Memory requirements

- Compatibility with automotive operating systems

3.2 Signal Conditioning Modules

Since ECUs interact with various sensors and actuators, signal conditioning modules help convert raw signals into usable data. These modules include:

- Analog-to-digital converters (ADC)

- Digital-to-analog converters (DAC)

- Filters and amplifiers

3.3 Automotive Communication Tools

Specialized tools are needed to interface with ECU communication networks. Common tools include:

- Vector CANoe: Used for developing, simulating, and testing CAN and LIN networks.

- dSPACE: Provides real-time simulation and validation tools.

- NI PXI: Offers modular instrumentation for automated testing.

3.4 Load Simulators and Actuators

To ensure ECUs function correctly under different operating conditions, the test system must include:

- Variable loads to replicate real-world electrical and mechanical stress.

- Actuators to mimic mechanical movement controlled by the ECU.

- Dynamic test rigs for simulating road conditions.

04. Software and Automation for ECU Testing

Automation plays a vital role in reducing human intervention, improving accuracy, and accelerating the ECU validation process. The key software solutions include:

4.1 Model-Based Testing

Using MATLAB Simulink, engineers can create virtual models of ECUs and test them under various conditions before deploying them on hardware.

4.2 Automated Test Scripts

Programming languages such as Python, CAPL, and LabVIEW are used to automate test execution, data collection, and analysis.

4.3 Test Management Tools

Managing ECU test cases and results requires specialized tools such as:

- IBM DOORS: For requirements tracking.

- JIRA: This is for issue tracking and test case management.

- Jenkins/GitLab CI/CD: This is for continuous integration and automated testing.

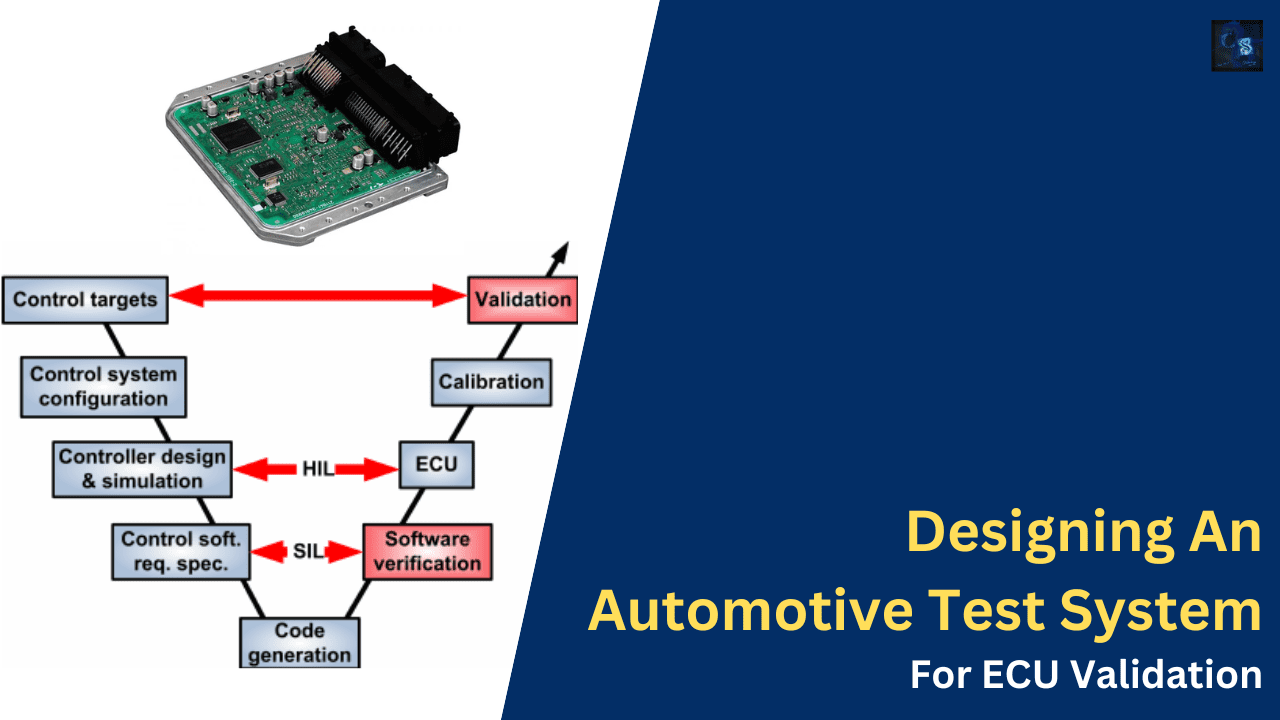

05. Hardware-in-the-loop (HiL) Testing

HiL testing integrates real ECUs with simulated vehicle environments, enabling engineers to:

- Test real-time performance and response times.

- Inject faults to assess ECU error handling capabilities.

- Simulate different driving conditions without needing a physical vehicle.

06. Software-in-the-loop (SiL) Testing

SiL testing is a cost-effective method to validate ECU software before deploying it on actual hardware. It helps in:

- Early detection of software bugs.

- Simulating thousands of test scenarios quickly.

- Reducing dependency on hardware prototypes.

07. Functional, Durability, and Cybersecurity Testing

To ensure an ECU performs reliably under all conditions, additional testing includes:

- Temperature and Vibration Testing: Simulating extreme conditions.

- Penetration Testing: Identifying potential security vulnerabilities.

- Electromagnetic Interference (EMI) testing: Ensuring compliance with automotive regulations.

08. Future Trends in ECU Validation

The future of ECU validation will be driven by emerging technologies such as:

- Artificial Intelligence (AI) for predictive analysis.

- Cloud-based testing for scalability.

- Digital twins for real-time simulation.

Conclusion

Designing an automotive test system for ECU validation requires a systematic approach, integrating hardware, software, automation, and security measures. By implementing best practices and leveraging modern technologies, engineers can ensure the reliability and safety of automotive ECUs, paving the way for the future of intelligent and connected vehicles.

This was about “Designing An Automotive Test System For ECU Validation“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?