Difference Between HiL, SiL, MiL In Automotive

Hello guys, welcome back to our blog. Here in this article, we will discuss the difference between HiL, SiL, MiL in Automotive, and architecture of HiL, SiL, and MiL.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

Also, read:

- Exploring Advanced Driver Assistance Systems (ADAS): The Future Of Safe Driving

- Safety Standards For Battery Management (BMS) In Electric Vehicles

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

Difference Between HiL, SiL, MiL

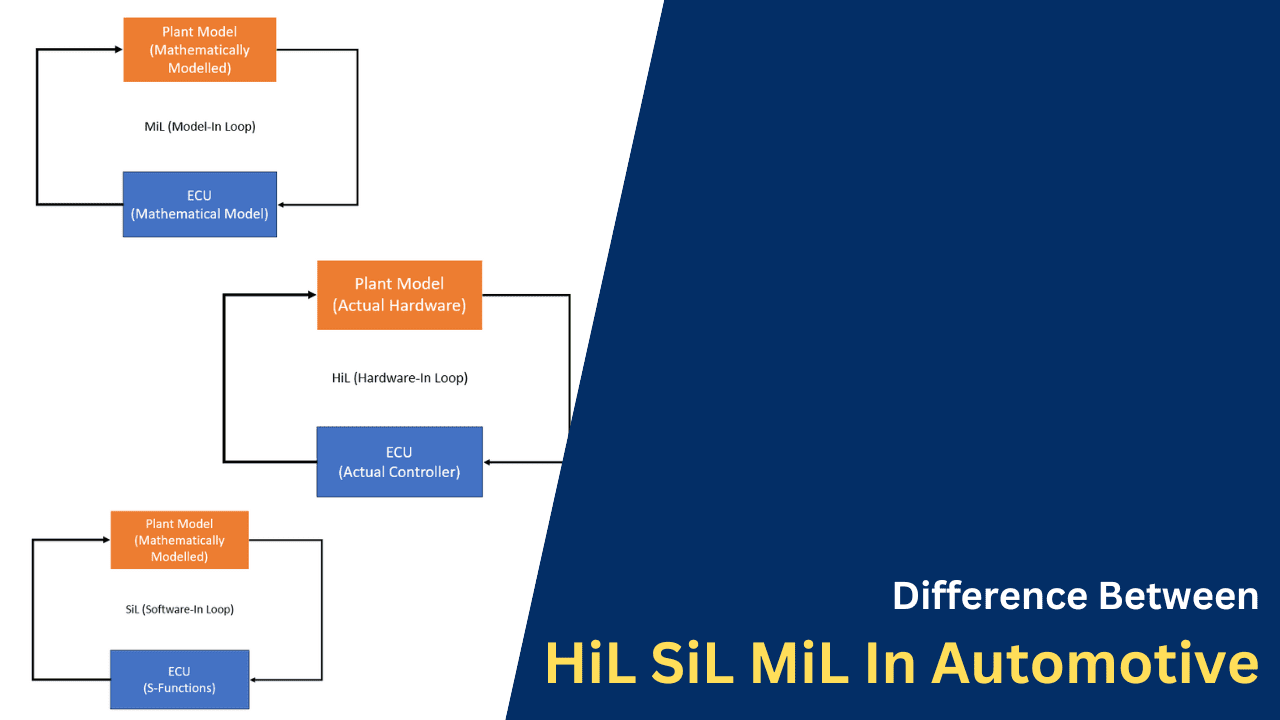

In the development of modern automotive systems, Model-in-the-Loop (MiL), Software-in-the-Loop (SiL), and Hardware-in-the-Loop (HiL) are integral techniques used for testing and validating control systems, embedded software, and hardware. These techniques are part of the Model-Based Design (MBD) approach, enabling iterative development, early error detection, and cost-effective testing in automotive applications.

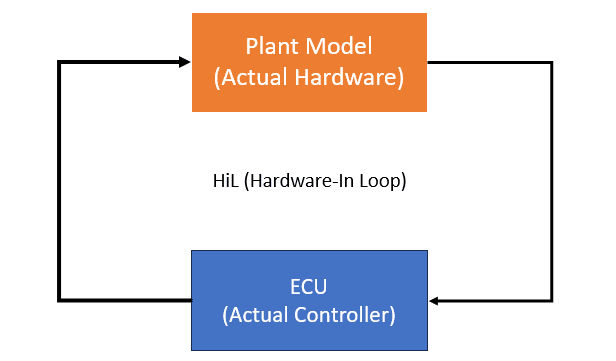

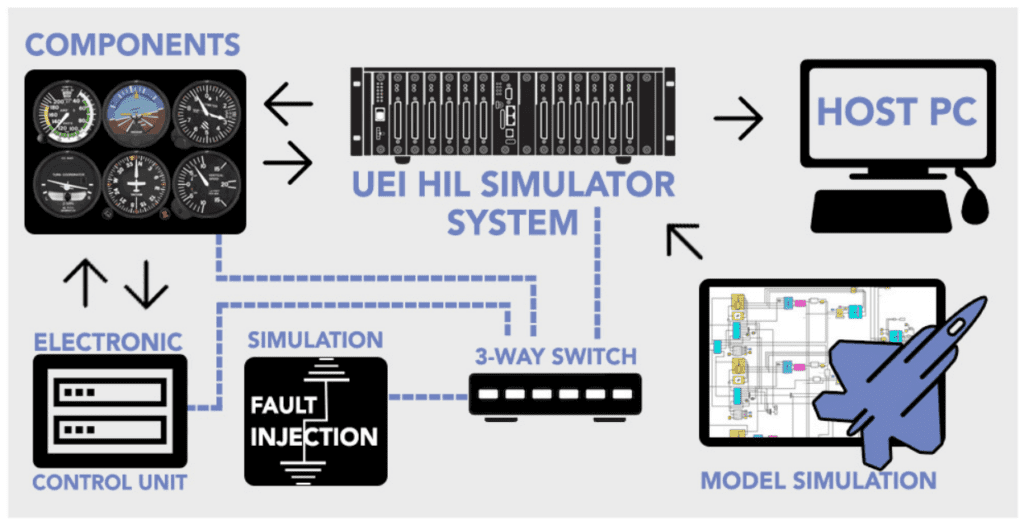

Hardware-in-the-Loop (HiL)

Hardware-in-the-Loop (HiL) is a simulation-based testing technique widely used in the automotive industry to validate and verify embedded systems. It bridges the gap between simulation and real-world testing, offering a cost-effective and efficient way to test control systems in automotive applications.

What is HiL?

HiL involves connecting a real-time simulation of a vehicle model with actual hardware components of the embedded system being tested. The key idea is to replace physical components (like the engine, brakes, or sensors) with mathematical models running in real time.

Why is HiL Important in Automotive?

- Cost-Effective: Reduces the need for physical prototypes, saving time and resources.

- Safety: Enables testing of safety-critical systems, such as airbags and ADAS (Advanced Driver Assistance Systems), in a controlled environment.

- Early Testing: Allows testing in early development stages before the complete vehicle is available.

- Real-Time Feedback: Provides instant results for system performance evaluation.

Applications of HiL in Automotive

- Engine Control Unit (ECU) Testing: Validates the functionality of engine control algorithms.

- Battery Management Systems (BMS): Ensures safe and efficient battery operations in electric vehicles (EVs).

- Advanced Driver Assistance Systems (ADAS): Tests systems like adaptive cruise control and lane-keeping assist.

- Chassis Systems: Simulates braking, steering, and suspension systems.

- Transmission Control Systems: Tests gear shifting and torque management.

Components of a HiL Setup

Real-Time Simulator:

- Executes the vehicle and environment models in real time.

- Examples: dSPACE, NI VeriStand, or Opal-RT.

Vehicle Model:

- Represents the dynamics of the car (engine, transmission, etc.).

- Typically developed using MATLAB/Simulink or similar tools.

Interface Hardware:

- Connects the real hardware (ECU or sensors) to the simulator.

I/O Modules:

- Manage analog, digital, and communication signals (e.g., CAN, LIN, FlexRay).

Control System Hardware:

- The actual ECU, sensor, or actuator is being tested.

Workflow in HiL Testing

- Develop and validate the vehicle model in a simulation environment.

- Integrate the embedded system hardware with the HiL setup.

- Perform real-time testing to evaluate system behavior under various scenarios.

- Analyze results and refine algorithms or designs.

Advantages of HiL in Automotive

- Enhanced Validation: Ensures software quality and system reliability.

- Accelerated Development: Speeds up the development process by parallelizing hardware and software testing.

- Scenario Testing: Allows testing of extreme or rare scenarios, such as sensor failures or adverse weather conditions.

Challenges in HiL Testing

- Complexity: Requires accurate real-time vehicle models.

- Cost of Setup: Initial investment in HiL tools and infrastructure can be high.

- Model Fidelity: Low-fidelity models may not represent real-world conditions accurately.

Future Trends

- Integration with AI/ML: For predictive analysis and adaptive testing.

- Cloud-Based HiL: To enable remote testing and collaboration.

- Increased Use for EVs: For validating electric powertrains, charging systems, and BMS.

HiL testing is indispensable in modern automotive development, ensuring high-quality, robust, and reliable embedded systems for vehicles of today and the future. Let me know if you’d like to dive deeper into any specific aspect!

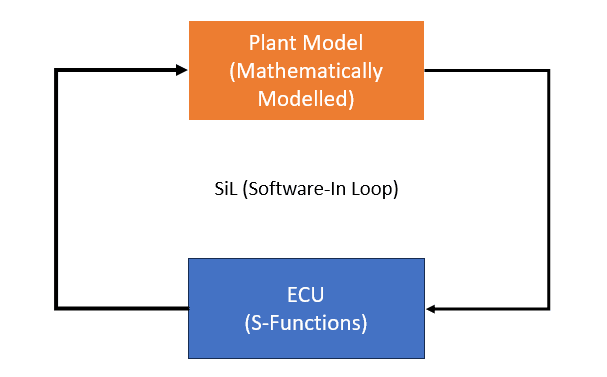

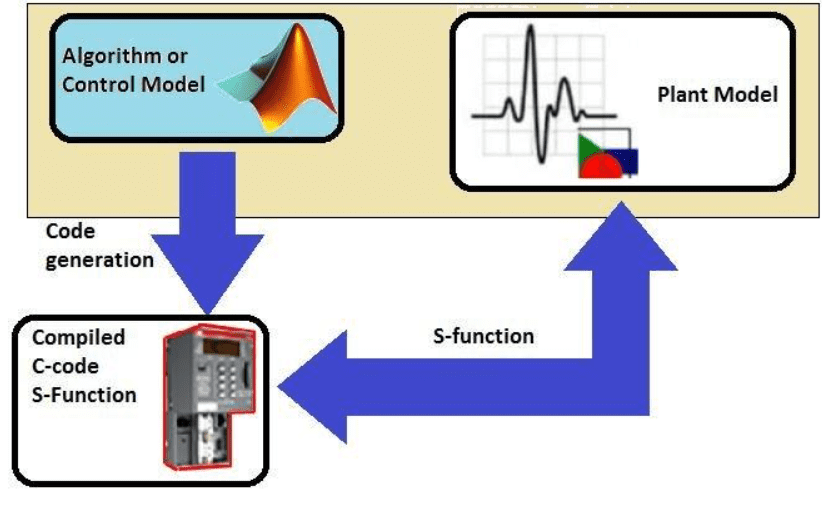

Software-in-the-Loop (SiL)

Software-in-the-loop (SiL) is a critical simulation-based testing technique used in the automotive industry to validate embedded software components during the development process. SiL testing focuses on verifying software functionality in a virtual environment without involving hardware, providing an efficient method to identify and address issues early in development.

What is SiL?

SiL testing involves running the embedded software on a virtual representation of the target hardware and integrating it with a simulated environment. This allows developers to test and debug software components without needing physical hardware.

Why is SiL Important in Automotive?

- Early-Stage Validation: This enables software testing before hardware prototypes are available.

- Cost-Effective: Reduces dependency on expensive hardware setups during initial development phases.

- Iterative Testing: Facilitates rapid iterations and improvements in software design.

- Comprehensive Coverage: Tests a wide range of scenarios that might be challenging or risky to reproduce on actual hardware.

Applications of SiL in Automotive

Algorithm Development: Used for control algorithms, such as engine control, braking systems, and energy management in electric vehicles (EVs).

Model-Based Development (MBD): Validates control models built in MATLAB/Simulink or other tools.

ADAS and Autonomous Systems: Tests perception, decision-making, and control algorithms for Advanced Driver Assistance Systems.

Powertrain and Transmission Control: Simulates software functionality for internal combustion engines, hybrid systems, and electric powertrains.

Battery Management Systems (BMS): Validates charging, discharging, and thermal management algorithms.

Components of SiL Setup

Software Models:

- Models of the control system, are typically developed in Simulink, LabVIEW, or C/C++.

Simulated Environment:

- Virtual models of the vehicle and environment, including sensors, actuators, and road conditions.

Test Platform:

- PC-based simulation tools such as MATLAB/Simulink, dSPACE, or Vector CANoe.

Communication Interfaces:

- Simulations of communication protocols like CAN, LIN, or FlexRay to mimic real-world network behavior.

Workflow in SiL Testing

Develop Control Software:

- Write algorithms using model-based or manual coding approaches.

Simulate Vehicle Behavior:

- Create a vehicle model to emulate physical system behavior.

Integrate Software:

- Run the control software on a simulated hardware platform.

Test Scenarios:

- Execute test cases for functional, performance, and failure scenarios.

Debug and Refine:

- Analyze results and refine software algorithms based on feedback.

Advantages of SiL in Automotive

- Early Bug Detection: Identifies software issues early in the development cycle, reducing downstream costs.

- Time Efficiency: Speeds up development by enabling parallel testing of software and hardware.

- Flexibility: Allows testing of edge cases and extreme conditions safely in a virtual environment.

- Scalability: Enables testing of multiple configurations and scenarios without requiring physical prototypes.

Challenges in SiL Testing

- Model Accuracy: Low-fidelity models can lead to discrepancies between simulated and real-world behavior.

- Simulation Limitations: Certain hardware-specific issues (e.g., timing or electromagnetic interference) cannot be replicated.

- Integration Complexity: Ensuring seamless integration of software with high-fidelity models requires expertise.

Comparison of SiL with Other Testing Techniques

| Testing Technique | Scope | Hardware Usage | Stage of Development |

|---|

| SiL | Tests embedded software in a virtual setup | No | Early |

| HiL | Tests embedded software with actual hardware | Yes | Intermediate |

| MiL (Model-in-the-Loop) | Tests algorithms using purely software models | No | Initial |

Future Trends

- AI-Based Simulations: Incorporating machine learning models to create more dynamic and realistic simulation environments.

- Cloud-Based Testing: Enabling distributed SiL testing for global collaboration and scalability.

- Integration with HiL: Creating unified workflows for seamless transitions between SiL and HiL.

SiL is an essential tool in the automotive industry, ensuring high-quality software design while reducing costs and time-to-market. Let me know if you’d like to explore a specific application or tool for SiL!

Model-in-the-Loop (MiL)

Model-in-the-loop (MiL) is a simulation-based testing method used in the early stages of the automotive development process. It involves creating and validating control algorithms using mathematical models in a simulated environment. MiL testing ensures that the functional behavior of the control systems is correct before implementing the software on hardware.

What is MiL?

MiL focuses on testing control algorithms represented as models in simulation tools like MATLAB/Simulink. These models interact with a virtual environment, simulating the vehicle dynamics and other real-world conditions. MiL testing does not require any hardware and is primarily used for developing and validating control strategies.

Why is MiL Important in Automotive?

- Early Validation: Allows testing and validation of algorithms early in the development lifecycle.

- Error Prevention: Identifies design errors before transitioning to Software-in-the-Loop (SiL) or Hardware-in-the-Loop (HiL) stages.

- Cost Savings: Reduces costs by addressing issues before hardware implementation.

- Accelerated Development: Enables iterative development and validation of control logic.

Applications of MiL in Automotive

- Powertrain Control: Testing algorithms for engines, transmissions, and hybrid systems.

- ADAS and Autonomous Systems: Developing control logic for features like adaptive cruise control, lane-keeping assist, and parking assistance.

- Battery Management Systems (BMS): Validating algorithms for managing battery charge, thermal control, and safety in electric vehicles (EVs).

- Chassis Systems: Testing braking, suspension, and steering control logic.

- Body Electronics: Validating lighting, climate control, and infotainment systems.

Components of a MiL Setup

Mathematical Models:

- Represent control systems and vehicle dynamics, often built in MATLAB/Simulink.

Simulated Environment:

- Models the external environment, including road conditions, weather, and traffic.

Simulation Tools:

- Platforms like MATLAB/Simulink, LabVIEW, or similar tools are used for model execution.

Test Cases:

- Scenarios are designed to evaluate the functional behavior of the control algorithms.

Workflow in MiL Testing

Model Development:

- Develop control system models using tools like MATLAB/Simulink.

Environment Modeling:

- Create vehicle dynamics and external environment models for simulation.

Integration:

- Combine control system models with environment models.

Test Execution:

- Simulate various scenarios and operating conditions to evaluate system behavior.

Analysis and Refinement:

- Analyze test results to identify and fix design flaws.

Advantages of MiL in Automotive

- Early Detection of Errors: Identifies functional and logic errors before transitioning to hardware testing.

- Rapid Prototyping: Speeds up the development of new features and control strategies.

- Reusability: Models can be reused in later stages, such as SiL and HiL testing.

- Safe Testing: Enables testing of critical and edge-case scenarios in a virtual environment.

Challenges in MiL Testing

- Model Accuracy: High-fidelity models are required to ensure realistic simulation results.

- Scalability: Complex systems may require significant computational resources.

- Validation Gap: Results may differ from real-world behavior due to the abstraction in models.

MiL in the Model-Based Design (MBD) Workflow

MiL is a foundational step in the Model-Based Design (MBD) approach:

- MiL: Develop and validate algorithms as models.

- SiL: Convert models to code and validate them in a virtual environment.

- HiL: Test the software with physical hardware in a simulated environment.

- Production: Deploy the validated software onto the target hardware.

Tools for MiL in Automotive

- MATLAB/Simulink: Widely used for control system modeling and simulation.

- dSPACE ASM: Provides real-time simulation models for automotive applications.

- CarMaker: Specialized in vehicle and environment simulation.

Future Trends in MiL

- AI-Driven Models: Using AI and machine learning to create more dynamic and adaptive vehicle models.

- Cloud-Based MiL: Leveraging cloud computing for collaborative and large-scale simulations.

- Integration with Virtual Reality (VR): Enhancing simulation realism using VR environments.

MiL is an indispensable part of the automotive development process, enabling efficient and reliable control system design. It lays the foundation for advanced testing techniques like SiL and HiL, ensuring the delivery of high-quality automotive systems. Let me know if you’d like to explore MiL tools or use cases in more detail!

This was about the “Difference Between HiL, SiL, MiL In Automotive”. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?

- Advanced Driver Assistance Systems (ADAS): How To Become An Expert In This Growing Field