Difference Between Three Point And Four Point Starter, DC Motor Starter

Hello guys, welcome back to blog. In this article, I will discuss the difference between three point and four point-starter, starters used in dc motor, how three point starter is different from four point starter, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask question. You can also catch me @ Instagram – Chetan Shidling.

Also, read:

- Difference Between BLDC And PMSM Motor, Brushless DC Motor.

- Top 10 Non-Renewable Power Plants In The World, Nuclear Power Plants.

- Difference Between Solar And Wind Power Plant, Renewable Energy.

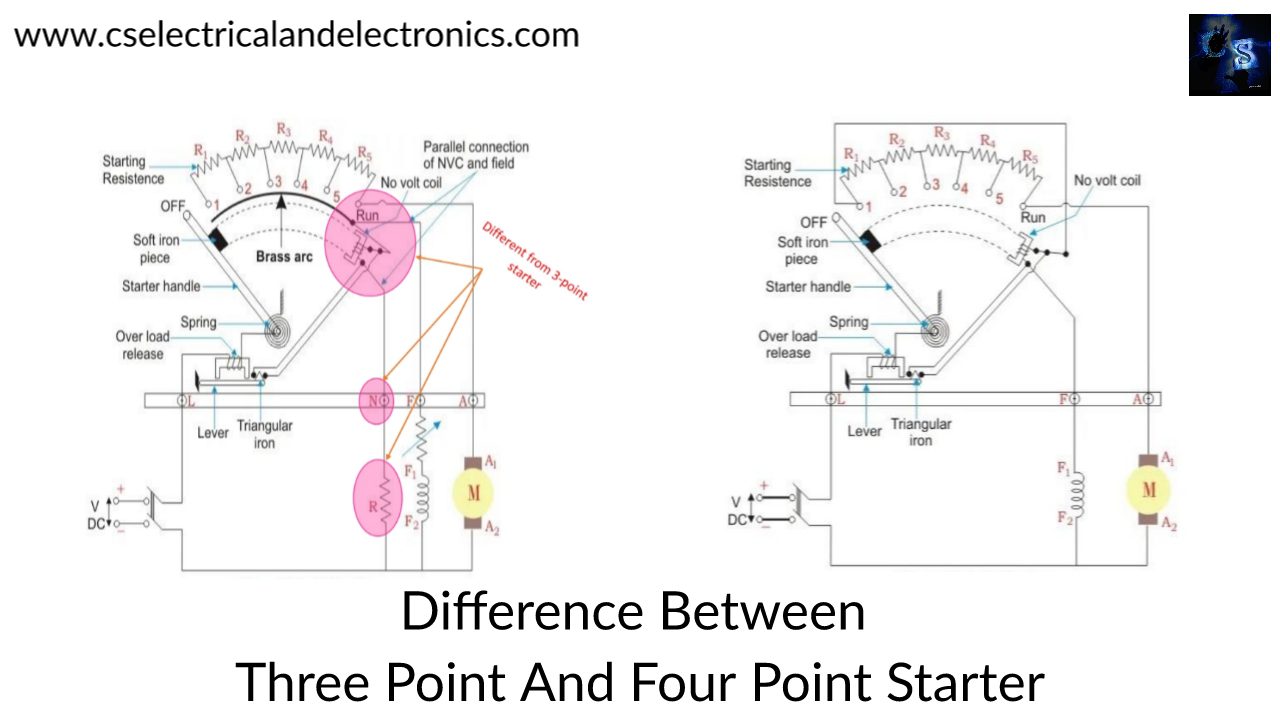

Difference Between Three Point And Four Point Starter

Necessity Of Pointer

The only reason for using a starter for the motor is the presence of a back-emf which plays a major role in governing the operation of the motor. When the motor armature rotates inside the magnetic field it will induce back emf, according to Faraday’s law of electromagnetic induction and oppose supply voltage. But back-emf at the start is zero, so nothing will oppose supply voltage, and starting current is dangerously high. One other reason is that we all know the armature resistance of the DC motor is very small.

In short, the starter will help in limit starting inrush current. Hear we will discuss 3-point & 4-point starters one by one and compare it.

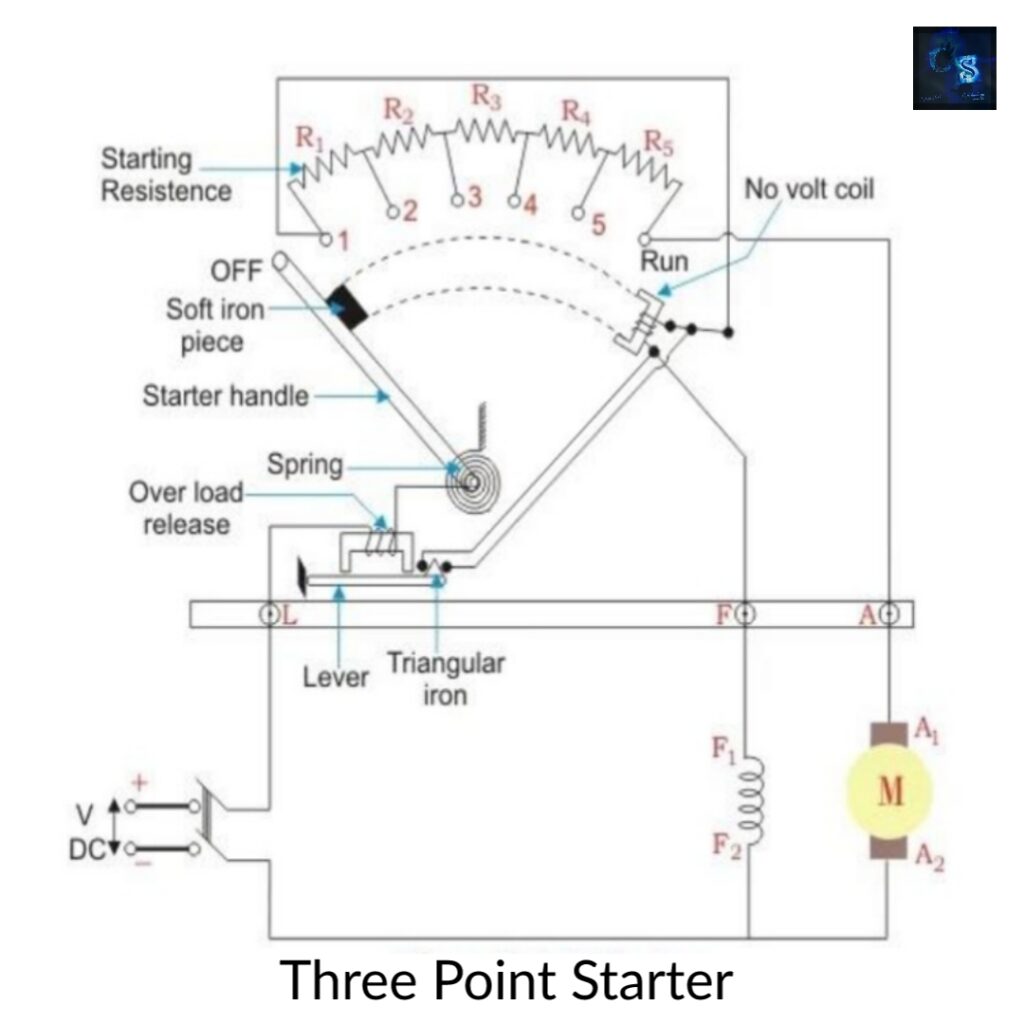

Three Point Starter

The construction of a starter is nothing but variable resistance. It is divided into a number of sections, called studs. All resistors connected with series with the armature and helps to limit starting inrush current.

As the name suggest 3-point_starter has 3 points or terminals.

- “L” line terminal which is connected to positive of supply.

- “A” armature terminal is connected to the armature winding.

- “F” field terminal which is connected to the field winding.

Other components of the starter are overload relay (OLR), conducting lever, no-volt coil (NVC). OLR is used for protecting purposes and NVC is used for protecting as well as holding the lever purpose.

The major drawback of a 3-point_starter is that it will face a problem when a motor with a large variation of speed is used. To increase the speed of the motor we have to increase field resistance. So, the flow of current is reduced, which results in a weak electromagnet and releases of the lever during normal operations, thus the motor is disconnected from the supply. This is not acceptable. A 4-point starter is come in as a pitcher to overcome this drawback.

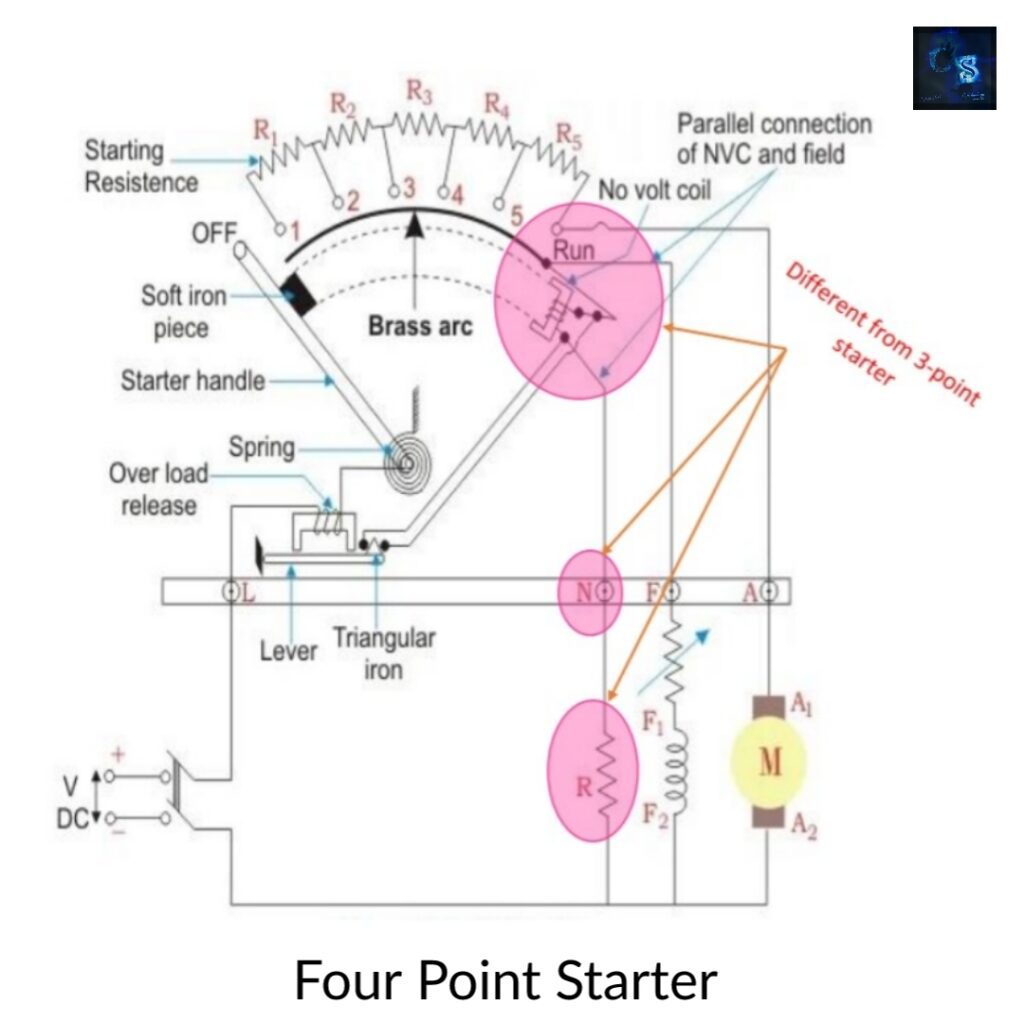

Four Point–Starter

The construction of a 4-point_starter is the same as a 3-point_starter. But as per the name 4-point_starter have one extra point which is

“N” – connected to no voltage coil (NVC)

“N” point has one additional resistance, called protective resistance. NVC also parallel connected with field winding, which is different from the 3-point_starter. This arrangement is used overcome to the drawback of the 3-point_starter. Also, it is preventing from a short circuit of the supply mains in case of overload release.

Difference Between Three Point And Four Point_Starter

| Three-Point Starter | Four Point Starter | |

| Numbers of points | 3-points | 4-points |

| Connection of NVC | In series with field winding | In parallel with field winding |

| Presence of protective resistance | No | Yes |

| Can we use a speed variable motor with it? | No | Yes |

I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024