Different Types Of Special Motors, Applications, Benefits, Working

Hello guys, welcome back to my blog. In this article, I will discuss different types of special motors, applications of different types of special motor, their advantages, disadvantages, and working of different types of special motors.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- EV Charging Station Installation Costs With The TATA Power Franchise

- Battery Pack Sizing Online Calculator For Electric Vehicles

- Battery C Rate Online Calculator With Time Calculation

Different Types Of Special Motors

There are mainly 4 different types of special motors:

- Servomotor.

- Stepper motor

- Universal motor.

- BLDC motor. ( Brushless DC motor )

Now, let’s discuss different types of special motors.

01. Servomotor

A servo system is one in which the output is the mechanical variable like position, acceleration, and velocity. These systems are automatic control systems in which the output is like controlling the position of the shaft etc.

The motors which will be used in such a servo system are called servomotor Servomotor will have a low power rating and can drive the load directly. That’s y these motors are usually coupled to the load, through a gear train for power matching purposes.

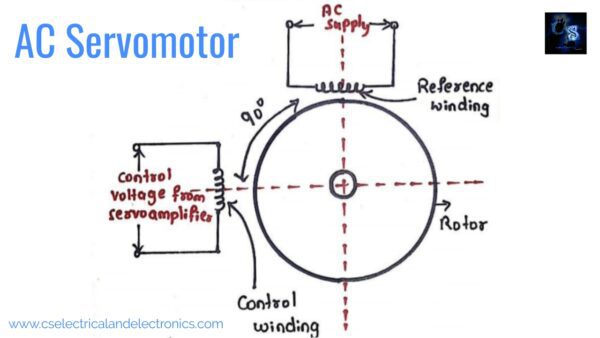

AC Servomotor

The servomotor used in the low power servo mechanism is the AC servomotor.

Operating Principle Of Servomotor

The operating principle of 2 phase AC servomotor will be similar to that of a normal 3 phase induction motor. The voltage control will be applied to the control winding and the voltage applied to the reference winding will be 90° out of phase. Then flux produces the current with the help of control winding, which is also 90° out of phase with respect to the flux produced by current through the reference winding.

The resultant flux in the air gap will be rotating in nature hence it is called a rotating magnetic field. Initially, the rotor part will be stationary, then as the rotating flux sweeps over the rotor, e.m.f gets induced in the rotor. This e.m.f will circulates the current through the rotor. The rotor current will produce its own flux which is called rotor flux. This flux will interact with the rotating magnetic field, which produces torque on the rotor.

Applications Of The Servomotor

- Used as instrument servos.

- It is used as a process controller.

- Used in robotics.

- It is used in self-balancing recorders.

- Used in machine tools.

- It is used as a position control system.

Advantages Of The Servomotor

- Having high output power.

- Accuracy and resolution are determined by encoders.

- Having high efficiency.

- Having 5 to 10 times more rated torque.

- Having 2 to 3 times more rated power.

Disadvantages Of The Servomotor

- It requires tuning to stabilize the feedback loop.

- It becomes unpredictable when something breaks.

- More expensive.

- Controlling the servomotor is complicated.

02. Stepper Motor

Introduction

This is the special type of DC motor, that converts input digital Pulses into mechanical shaft rotation. It converts a train of Input pulses (square wave pulses ) into a precisely defined increment in the shaft position. Every pulse of the square wave moves the shaft of the stepper motor through a fixed angle so we can define the stepper motor as “This is as electrochemical which actuates train of step movements of the shaft with respect to the train of input pulses. “

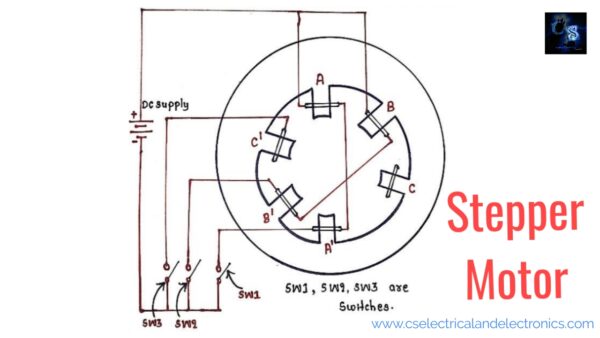

Operation Of The Stepper Motor

The stepper motor works on the principle of Electromagnetism. It consists of two main parts.

- Rotor.

- Stator.

For the rotor, we can use a permanent magnet or soft iron and the rotor part will be surrounded by electromagnetic stators. If we give a voltage at terminals, the rotor tries to align with the stator. Here I would like to take the stepper motor which consists of 4 pole rotor construction. i.e. rotor is having 4 salient poles without any exciting winding.

Stages In Stepper Motor

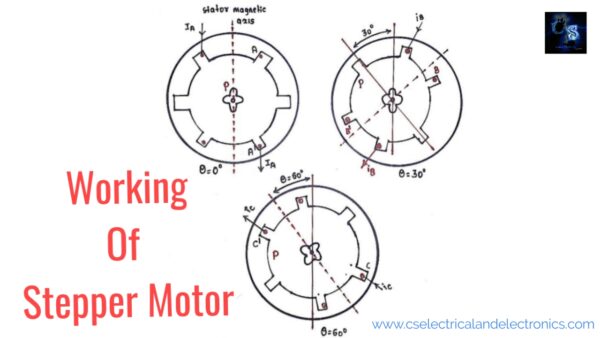

When we excite AA’ phase by keeping the SW1 switch as close, then the stator magnetic axis aligns along the poles formed due to AA’ ( vertical ). Then the rotor tries to adjust itself in a minimum reluctance position i.e. matching its own axis which passes through the two poles exactly with the stator magnetic axis.

Then next when we excite phase BB’ by keeping the SW2 switch close and the AA’ phase de-energized by keeping the SW1 switch open. Now the stator magnetic axis shifts towards the pole which is formed by BB’. Then again rotor tries to align with minimum reluctance & it will turn by a 30° step angle in an anti-clockwise direction. The axis passing along two diagonally opposite poles of the rotor will match with the stator magnetic axis. Point P will be a new position of minimum reluctance.

Then next when we excite phase CC’ by keeping the SW3 switch close and AA’ and BB’ phases are de-energized by keeping SW1 & SW2 switches open. Now the stator magnetic axis shifts towards the poles formed due to CC’. Then the rotor tries to align with minimum reluctance & it will turn by a 60° step angle in an anti-clockwise direction.

After exciting the three phases, the motor takes 12 steps to complete one full revolution.

Advantages Of Stepper Motor

- Used in X-Y plotters.

- It is used in the floppy disk drive.

- Used in machine tools.

- It is used in the process control system.

- Used in robotics.Used in printers.

- It is used in tape drives and a variety of other industrial applications.

Disadvantages Of Stepper Motor

- It’s having low efficiency.

- Torque drops rapidly with speed.

- Having low output power for size.

- Missing feedback to indicate missed steps.

- Heat experience in the high-performance configuration.

- Low accuracy at full load.

03. Universal Motor

Introduction

“Universal motor can be operated on both DC & single-phase AC supply. This can be also called a “single-phase series motor”. These motors will be having high starting torque. This is the main feature of universal motors.

Working Of Universal Motor

As the definition says, the universal motor works on both DC & single-phase AC supplies. If we give a DC supply to the universal motor, it works as a DC series motor. i.e. if current flows through the field winding, then it will produce an electromagnetic field and the same current will flows through armature conductors. When we placed a current-carrying conductor in an electromagnetic field, it will experience a mechanical force. Due to this force, the rotor will rotate. The direction of the mechanical force will be explained by using “ Fleming’s left-hand rule”.

If we give AC supply, then it produces unidirectional torque. It’s because both the winding of the motor are connected in series, which means they are in the same phase. But polarity of AC supply changes periodically, due to this action the direction of the current in both winding, reverses at the same time. Then the direction of the magnetic field & armature current reverses in such a way that the direction of the force experienced by armature conductors remains the same. Thus the matter of AC or DC supplies the Universal motor works.

Applications Of Universal Motor

- Can be used for domestic applications such as vacuum cleaners, food, mixers, hair drains, electric shavers, etc.

- Can be used in blowers.

- Used in portable tools like drilling machines and small drives.

- Non compensated universal motors can be used whenever there is a requirement for low horsepower.

- Compensated universal motors can be used whenever there is a requirement for high horsepower.

Advantages Of Universal Motor

- Less costly as compared to other motors.

- The capacity for producing good torque at low speed.

- Preferred in many portable tools due to less size.

- The capacity of running at an adjustable speed.

Disadvantages Of Universal Motor

- High noise

- It will be difficult to run a universal motor in the opposite direction.

- Overheating if the motor takes place, to avoid this, we require fresh air.

- Requires frequent service and maintenance.

04. Brushless DC Motor

BLDC stands for “ Brushless Dc motor”. That means these motors do not have brushes in them. Brushless DC electric motors can also be called electronically commutated motors, which are powered by DC electric source through an integrated inverter or switching power supply, which produces an AC electric signal to drive the motor.

Working Of BLDC Motor

First, let’s see the function of a brushed motor. In brushed motors, there will be permanent magnets on the outside and a spinning armature. This spinning armature contains an electromagnet. This electromagnet creates a magnetic field in the armature when supply is given and helps to rotate the armature. To keep the rotation of the armature, the brushes will change the polarity of the pole.

The working principle of brushed DC motor and brushless DC motor is the same. i.e internal shaft position feedback. The brushless DC motor has two windings. Rotor and stator. The rotor is a rotating part and has rotor magnets in it. Where stator is stationary winding that consists of the stator.

In the rotor, the permanent magnets are attached. To activate electromagnets, high-power transistors are used. The controller performs power distribution by making use of the solid-state circuit.

Application Of BLDC Motor

- Can be used in servo actuation.

- Positioning and variables speed.

- Can be used in aerospace.

- Used in air conditioners.

- It is used in computer peripheral equipment.

- Used in biomedical instrumentation.

Advantages Of BLDC Motor

- Low maintenance cost.

- These are having a long life.

- Low friction and low inertia.

- High efficiency (>75%).

- Reliable operation.

Disadvantages Of BLDC Motor

- More expensive

- Having a complex network.

- It needs complex electronic controllers.

I hope this article may help you all a lot. Thank you for reading. I think now you are clear about different types of special motors. If you have any doubts about different types of special motors then comment below.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Automotive Interview Questions With Answers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students