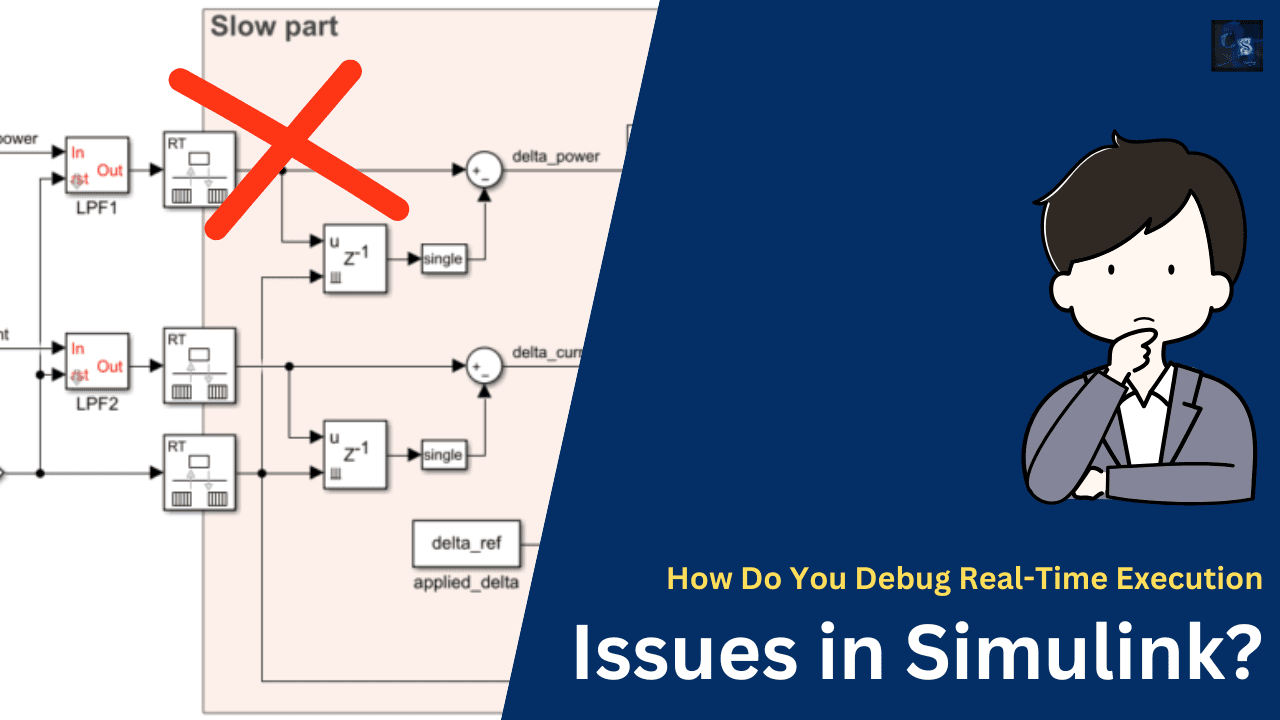

How Do You Debug Real-Time Execution Issues in Simulink?

Hello guys, welcome back to our blog. In this article, I will discuss debudding real-time execution issues in Simulink and some common real-time execution issues and solutions.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- XCP (Universal Measurement And Calibration Protocol) – A Complete Guide

- Designing An Automotive Test System For ECU Validation

- Top 30 Automotive-Specific ISO Standards Every Automotive Engineer Must Know

Debug Real-Time Execution Issues in Simulink

Simulink is a widely used tool for model-based design (MBD) across various industries, including automotive, aerospace, industrial automation, and robotics. It provides a visual programming environment for designing, simulating, and testing dynamic systems. When developing real-time applications, engineers often face execution issues that can lead to missed deadlines, unstable behavior, or inefficient computation.

In real-time systems, meeting strict timing constraints is crucial. Unlike offline simulations where performance bottlenecks may not have immediate consequences, real-time systems must ensure that computations are completed within fixed time steps. If the system fails to execute within the allocated time, the consequences can range from degraded performance to catastrophic failures.

Debugging real-time execution issues in Simulink-based Hardware-in-the-Loop (HiL) testing environments and embedded controllers requires a systematic approach. Engineers need to identify bottlenecks, optimize execution time, and ensure efficient use of memory and computing resources. This article explores the challenges in real-time execution, the available debugging tools, and practical solutions to overcome execution issues in Simulink.

Understanding Real-Time Execution in Simulink

What Is Real-Time Execution?

Real-time execution refers to a system’s ability to process inputs, compute required actions, and generate outputs within a fixed time constraint. Unlike non-real-time systems, where computation time can vary without serious consequences, real-time systems must complete execution within a predetermined deadline to function correctly.

For example, in an Advanced Driver Assistance System (ADAS), real-time execution ensures that an emergency braking system detects an obstacle and responds within milliseconds. Any delay beyond the acceptable limit may result in failure to prevent a collision.

Real-time execution is categorized into:

- Hard Real-Time Systems: Missing deadlines lead to complete system failure (e.g., flight control systems, anti-lock braking systems).

- Soft Real-Time Systems: Occasional delays are tolerable but may reduce performance (e.g., multimedia streaming, data acquisition systems).

Challenges in Real-Time Execution

Real-time execution in Simulink is affected by several factors, including:

- Computational Load – Complex models require significant processing power, which can exceed the available CPU time.

- Task Scheduling Issues – Improper execution order of tasks can cause priority conflicts and delays.

- Memory Limitations – High memory consumption may slow execution or lead to memory overflows.

- Timing Variability (Jitter) – Variations in task execution times can cause inconsistent system behavior.

- Solver Selection – Choosing an inefficient solver may introduce delays in numerical computations.

Each of these challenges requires careful analysis and debugging to ensure smooth real-time execution.

Debugging Tools in Simulink for Real-Time Execution

01. Simulink Profiler

The Simulink Profiler is a tool that helps analyze the execution time of blocks, subsystems, and the entire model. It provides detailed reports on the computational load of individual components, helping engineers identify performance bottlenecks.

How to Use Simulink Profiler?

- Open the Simulink model.

- Navigate to Debug → Performance Advisor → Simulink Profiler.

- Click Run Profiler to generate an execution time breakdown.

- Identify blocks consuming excessive computation time and optimize them.

Example: Improving Execution Time in an Engine Control System

A company working on Engine Control Unit (ECU) software noticed that their model execution time was exceeding real-time constraints. Using Simulink Profiler, they found that fuel injection calculation blocks consumed excessive CPU time. By replacing complex floating-point calculations with precomputed lookup tables, execution speed improved significantly.

02. Execution Profiling

Execution profiling allows engineers to measure computation time for each time step, helping identify task overruns. It is particularly useful in real-time simulations where missing a deadline can lead to serious consequences.

Steps to Enable Execution Profiling

- Open the Simulink Real-Time model.

- Navigate to Simulation → Execution Profiler.

- Enable profiling and run the model to capture execution data.

- Analyze time step execution logs to identify delays.

Example: Fixing Execution Delays in Autonomous Navigation

An autonomous vehicle development team found that their path-planning algorithm sometimes caused frame drops, leading to unstable vehicle movement. Execution profiling revealed that real-time obstacle detection was taking too long to execute. By optimizing the image processing pipeline using parallel computation, they reduced execution time and stabilized navigation.

03. Real-Time Explorer

The Real-Time Explorer allows engineers to monitor execution time, memory usage, and signal values in real time without stopping the model. It is especially useful in HiL simulations and ECU validation.

Key Features of Real-Time Explorer

- Live signal monitoring to detect anomalies in system behavior.

- CPU utilization tracking to prevent excessive computational load.

- Memory profiling to optimize data storage.

Example: Monitoring ECU Performance in a Brake-by-Wire System

A brake-by-wire system experienced occasional delays in braking response. Using the Real-Time Explorer, engineers identified memory spikes caused by the excessive logging of sensor data. By limiting the logging rate and optimizing data storage, they improved real-time response.

Common Real-Time Execution Issues and Solutions

01. Overruns (Missed Deadlines)

Problem: The system fails to complete execution within the allocated time step, leading to missed deadlines.

Solution:

- Reduce model complexity by optimizing computations.

- Use fixed-step solvers instead of variable-step solvers.

- Precompute results and use lookup tables where possible.

- Offload tasks to parallel processing units (FPGA, GPU, multicore CPUs).

Example: Reducing Overruns in ABS Control

A real-time ABS (Anti-lock Braking System) simulation had frequent overruns due to complex traction control computations. Engineers optimized the model by reducing the resolution of sensor input processing, ensuring all computations completed within the required time step.

02. Jitter (Execution Time Variability)

Problem: Variations in task execution time lead to inconsistent system behavior.

Solution:

- Use fixed-step discrete solvers for deterministic execution.

- Align task scheduling with hardware clocks.

- Eliminate unnecessary asynchronous computations.

Example: Eliminating Jitter in Power Inverter Control

A power inverter controller suffered from PWM signal instability due to execution jitter. By switching to hardware-timed execution, engineers eliminated variations, resulting in stable motor control.

03. Memory Overuse and Logging Issues

Problem: Excessive memory usage slows execution and may cause real-time failures.

Solution:

- Reduce unnecessary logging of signal data.

- Use compressed data storage formats.

- Optimize memory allocation for real-time tasks.

Example: Optimizing Memory in Battery Management Systems (BMS)

A Battery Management System (BMS) experienced delays due to high-frequency voltage and temperature logging. Engineers optimized logging frequency and switched to on-chip memory storage, significantly improving execution performance.

Conclusion

Debugging real-time execution issues in Simulink requires a systematic approach using profiling tools, solver optimizations, and hardware-specific techniques. The most effective strategies include:

- Using Simulink Profiler, Execution Profiling, and Real-Time Explorer to analyze performance.

- Identifying and fixing overruns, jitter, and memory inefficiencies.

- Optimizing computationally intensive blocks by reducing complexity and leveraging hardware acceleration.

- Implementing best practices for real-time simulation in HiL and ECU environments.

By following these techniques, engineers can ensure reliable, real-time performance in mission-critical applications such as automotive control systems, aerospace navigation, and industrial automation.

This was about “How Do You Debug Real-Time Execution Issues in Simulink?“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?