Hello guys, welcome back to my blog. In this article, I will discuss how to avoid thermal runaway in electric vehicles, and what factors we have to consider step by step I will explain.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- Top 08 Functions Of The Battery Management System, BMS Functions

- Top Reason Why Electric Bikes Are Catching Fire? Be Safe

- 1st Oder RC Circuit And 2nd Order RC Equivalent Circuit SoC Estimation

How To Avoid Thermal Runaway In Electric Vehicles

When the lithium-ion batteries/cells get overheated and catch fire due to various causes (such as lack of cooling system, overcharging, short circuit) is known as a thermal runaway in electric vehicles. Thermal runaway starts when the heat developed within a battery surpasses the quantity of heat that is dispersed to its surroundings.

Challenges engineers are facing to avoid thermal runaway in lithium-ion cells

- 01. Choose the cell chemistry, and pre-size the battery pack.

- 02. Check the integration in the electrified driveline.

- 03. Predict & control the impact of the aging effect.

- 04. Validate the battery management system.

- 05. Design the cooling system & thermal management.

- 06. Easily characterize battery cells from experiments.

Solutions to avoid thermal runaway in lithium-ion cells

- 01. Determine battery requirements for vehicle performance & fuel consumption / range targets.

- 02. Get a first battery design meeting the requirements starting from a database of commercial lithium-ion cells.

- 03. Design & analyze electrochemical reactions & detailed geometry of battery cells.

- 04. Calculate 3D thermal, fluid & electrochemical properties of battery modules & packs.

Let’s discuss from the beginning what all factors or things you have to consider to avoid thermal runaway in lithium-ion cells.

01. Battery Beginning/Early Design: The early design sizing for any kind of vehicle architecture.

- Start from the requirements at the vehicle level.

- Generate the electrified vehicle architecture with functional models & very limited data.

- Define the cell/battery capacity & power on certified test procedure or custom drive cycle.

You have to follow proper standards and rules to design a battery for a particular vehicle.

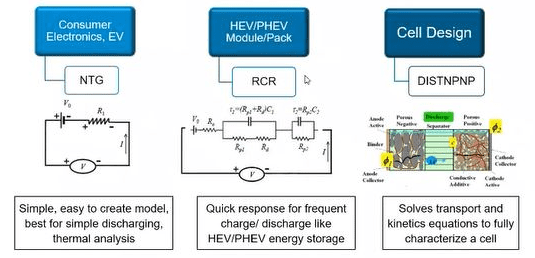

02. Electrode & Cell Design:

Select the proper quality of lithium-ion cells and conduct various tests on cells. To check the quality of cells, don’t use local quality lithium-ion cells.

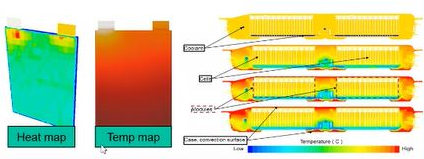

Simulate through a coupled resolution the cell electrochemical behavior with a thermal environment. Compute the cell heat 3D distribution for high accuracy temperature map prediction. Resolve complex cooling system.

03. Pack Design:

Proper sizing of the pack is one of the important factors. While designing it make sure cells are connected in proper order with proper insulating material. Also, check the initial conditions of all cells like state of health and state of charge. If any cells are degraded replace them with the new cell.

04. Pack Integration:

Each pack has one slave controller to monitor the states of pack cells. After integration, check the condition of the slave controller whether it is providing accurate state results or not. Also, check the connections between the packs whether proper insulation and connections are done or not.

05. Battery safety:

Make sure the battery is providing safety systems like fault management, thermal management, pyro switches, and any safety systems. Test battery under various charging, discharging, and HPPC tests. Also, test fault management and thermal management systems are working or not in various conditions.

06. Battery management system:

BMS plays a very important role such protecting the battery pack from various conditions. To monitor and maintain the battery pack for proper usage, a BMS is needed. The main functions of BMS are:

- Cell balancing: equalizing the Soc and voltage of each cell.

- Protecting the battery pack from overcurrent, overvoltage, & under-voltage conditions.

- Monitoring the temperature, & isolating the BMS if the temperature exceeds.

- Monitoring current, voltage, SoC (state of charge), SoH (state of health), SOP (state of power), and SOE (state of energy).

- Efficient control of charging & discharging.

- Control the cooling system

If you are going to use a low-quality BMS, then it may operate in good condition for one year. And later you may face any issues regarding the battery management system. Make sure you utilize a high-quality BMS for your battery pack.

This was about “How To Avoid Thermal Runaway In Electric Vehicles“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 100+ Indian Startups & What They Are Building

- 1000+ Automotive Interview Questions With Answers

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024