Importance Of Pressure Release & Venting Mechanisms In EV Batteries

Hello guys, welcome back to our blog. In this article, we will discuss the importance of pressure release and venting mechanisms in EV batteries, types of venting mechanisms, and safety regulations.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- How Blockchain Can Improve Automotive Data Security

- ISO 21434: Road Vehicles – Cybersecurity Engineering A Complete Guide

- Why Is C Or C++ Better Than Python For Embedded Systems?

Pressure Release & Venting Mechanisms In EV Batteries

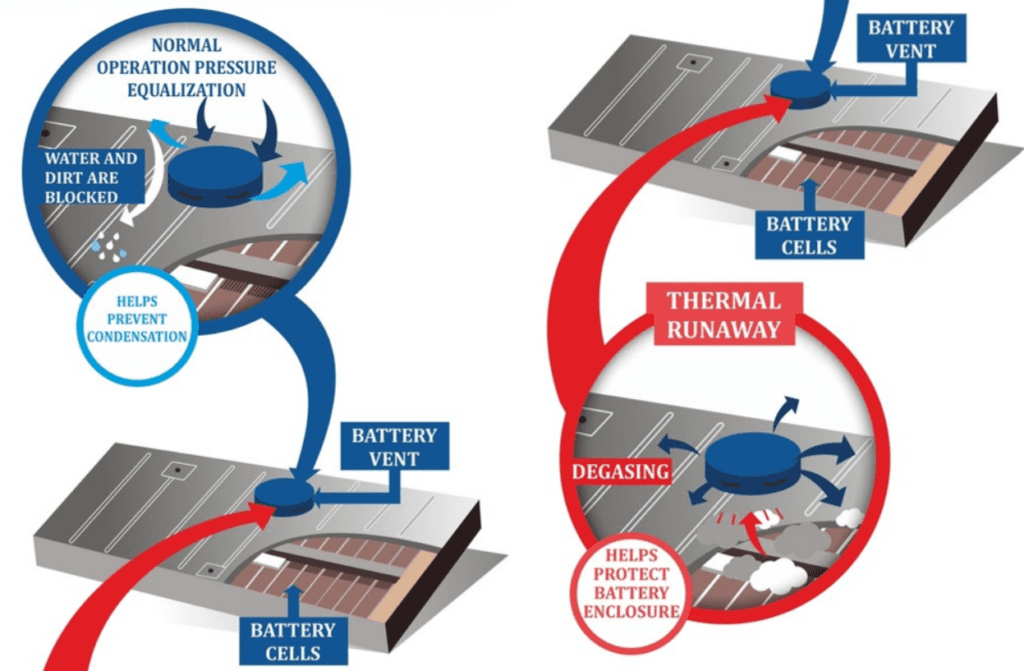

Electric Vehicle (EV) batteries are complex energy storage systems that must operate safely under various conditions. One of the key concerns in battery safety is thermal runaway, a condition where excessive heat buildup leads to uncontrollable reactions within the battery. To mitigate this, pressure release and venting mechanisms play a critical role in preventing catastrophic failures, such as explosions or fires. This article explores the need for these safety features, different venting mechanisms, their working principles, and advancements in pressure release technologies for EV batteries.

Why Are Pressure Release and Venting Mechanisms Necessary?

Lithium-ion batteries, commonly used in EVs, contain flammable electrolytes that can generate gas and heat under stress conditions. Factors leading to dangerous pressure buildup include:

- Overcharging – Leads to electrolyte decomposition and gas formation.

- Short circuits – Internal or external short circuits cause rapid heating.

- Mechanical damage – Accidents or punctures can rupture battery cells.

- Overheating – High temperatures accelerate side reactions and gas formation.

- Manufacturing defects – Impurities or poor-quality separators can lead to internal failures.

Without proper pressure release mechanisms, these issues can cause battery rupture, leakage, or even explosions, posing serious safety risks to users and vehicles.

Types of Venting Mechanisms in EV Batteries

01. Cell-Level Venting

Each individual battery cell is equipped with a venting mechanism to release internal gases safely when pressure crosses a critical threshold. These include:

- Rupture Discs – Thin metal membranes designed to break under high pressure, allowing gas escape.

- One-Way Valves – Prevent gas entry while allowing safe venting when pressure builds.

- Pressure Relief Grooves – Predefined weak spots in battery casings that break in a controlled manner to release excess pressure.

02. Module-Level Venting

Battery modules (groups of cells) incorporate additional safety measures to safely direct vented gases away from cells and vehicle occupants. These include:

- Internal Venting Channels – Direct gas flow toward a safer exit point.

- Flame Arrestors – Prevent flames from propagating inside the module.

- Cooling Pathways – Assist in dissipating heat generated during venting.

03. Pack-Level Venting

At the pack level, vehicle manufacturers integrate large-scale venting mechanisms that handle high-pressure scenarios effectively. Key solutions include:

- High-Pressure Relief Valves (PRVs) – Automatically open when gas pressure reaches unsafe levels.

- Thermal Fuses – Trigger venting when temperatures exceed critical limits.

- Directional Venting – Ensures expelled gases are directed away from passengers and sensitive vehicle components.

How Venting Mechanisms Work

01. Normal Operation

Under normal conditions, battery cells generate minimal gases due to controlled electrochemical reactions. Venting systems remain inactive in this state.

02. Early Signs of Failure

If a battery experiences minor overheating or overcharging, pressure begins to build up. Certain venting designs, such as microporous separators, allow minor gas diffusion without triggering full-scale venting.

03. Triggering Venting Systems

When the pressure reaches a threshold (typically 5-10 psi for cells, 30-60 psi for packs), rupture discs or pressure relief valves activate, allowing gases to escape in a controlled manner. In some designs, the venting pathway includes a filter or flame arrestor to minimize fire risks.

04. Post-Venting Stabilization

After venting, thermal management systems (such as coolant circulation or phase-change materials) work to restore battery stability and prevent further degradation.

Advances in Pressure Release & Venting Technologies

01. Smart Venting Systems

Modern EV batteries incorporate electronic pressure sensors that monitor gas buildup and trigger automated venting when necessary. This approach enhances response time and prevents unnecessary venting cycles.

02. Chemical Gas Absorption Materials

Some next-generation battery packs use materials that absorb toxic gases (such as HF—hydrogen fluoride) released during thermal runaway. These materials improve passenger safety by reducing exposure to harmful emissions.

03. Dual-Stage Venting

A two-stage venting system includes:

- Low-pressure release – Handles minor overpressure scenarios.

- High-pressure emergency venting – Activates during critical failures, ensuring rapid pressure dissipation.

04. Solid-State Battery Venting

Solid-state batteries generate less gas compared to liquid-electrolyte-based Li-ion batteries. However, manufacturers still include micro-venting structures to handle pressure anomalies safely.

Safety Regulations and Industry Standards

To ensure EV battery safety, global regulatory bodies enforce strict standards on venting and pressure release mechanisms. Key regulations include:

- UN 38.3 – Covers transport safety of lithium batteries.

- SAE J2464 – Battery safety testing procedures.

- UL 2580 – Battery safety for electric vehicles.

- IEC 62660-2 – Performance and safety testing for lithium-ion cells in automotive applications.

- FMVSS 305 – U.S. regulation focusing on EV crash safety, including venting.

Compliance with these standards ensures that EV batteries can handle extreme conditions without endangering passengers or first responders.

Challenges and Future Innovations

While current venting mechanisms offer effective safety solutions, there are still challenges:

- Gas Toxicity – Even with venting, harmful gases like CO, HF, and hydrocarbons pose health risks.

- Size and Weight – Advanced venting designs must be compact to maintain battery energy density.

- Heat Management – Effective cooling integration is necessary to prevent further ignition post-venting.

Future Innovations

- Nanoporous Membranes – Allow controlled gas release while preventing electrolyte leakage.

- AI-Powered Venting – Uses machine learning to predict failures and trigger pre-emptive venting.

- Self-Healing Materials – This can restore minor ruptures and prevent unnecessary venting.

- Non-Flammable Electrolytes – Reduce the need for aggressive venting by preventing gas formation altogether.

Conclusion

Pressure release and venting mechanisms are critical to the safe operation of EV batteries, preventing thermal runaway and ensuring vehicle safety. Advances in smart venting, dual-stage relief systems, gas-absorbing materials, and AI-powered monitoring are pushing battery safety to new levels. As EV adoption grows, continued innovation in pressure-release technology will be key to making electric mobility even safer and more reliable in the future.

This was about the “Importance Of Pressure Release & Venting Mechanisms In EV Batteries“. Thank you for reading.

Also, read:

- The Future Of Battery Management Systems In The Era Of Software Defined Vehicles

- Automotive-Grade Microcontrollers Vs General-Purpose MCUs: What Sets Them Apart?

- Upcoming Technologies To Learn In The Automotive Industry To Get High-Paying Jobs

- How Is DoIP Different From CAN-based Diagnostics?

- Difference Between Domain And Zonal Architecture in Automotive: A Complete Guide

- Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer

- 1000+ Automotive Interview Questions With Answers

- RTOS In The Automotive Industry: The Brains Behind Real-Time Vehicle Control