Hello guys, welcome back to our blog. In this article, I will discuss an in-depth guide to UDS service 0x19 ReadDTCInformation, sub-functions of service 19, and status bytes.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Testing Techniques For Test Case Writing in the Automotive Domain

- Different Storage Classes In MATLAB Simulink

- Mini Project / Hands-on Demo for Software-Defined Vehicles (SDVs): Part 08

In-Depth Guide To UDS Service 0x19 – ReadDTCInformation

Unified Diagnostic Services (UDS) is a standardized protocol used in the automotive industry for diagnostics and communication between the tester (diagnostic tool) and Electronic Control Units (ECUs). Service 0x19, known as “ReadDTCInformation,” is a critical part of the UDS protocol, enabling the retrieval and interpretation of Diagnostic Trouble Codes (DTCs). These DTCs help service technicians and engineers diagnose faults in a vehicle’s system.

In this article, we will cover every sub-function of Service 0x19, explain the DTC status byte, examine a real-world DTC (P0301), and explore various use cases and diagnostic applications. With over 5000 words of in-depth content, this article aims to provide an exhaustive understanding of UDS Service 0x19.

Introduction to Service 0x19 (ReadDTCInformation)

UDS Service 0x19 allows diagnostic testers to retrieve DTCs stored in the ECU. These DTCs provide vital information about malfunctions that have occurred in the vehicle’s subsystems. The purpose of this service is to:

- Retrieve DTCs based on status masks or severity

- Access snapshot and extended data records

- Provide emissions-related diagnostic information

- Support On-Board Diagnostics (OBD) compliance

Sub-functions of Service 0x19

Each sub-function under Service 0x19 offers a specific capability for retrieving or reporting DTC-related information. Below is a detailed breakdown of all subfunctions:

01. 0x01 – ReportNumberOfDTCByStatusMask: This sub-function returns the number of DTCs that match a specific status mask. The diagnostic tester sends a status mask in the request, and the ECU responds with the count of DTCs having those status bits set. Useful for quickly assessing the health status of a vehicle.

02. 0x02 – ReportDTCByStatusMask: This sub-function retrieves a list of all DTCs that match the given status mask. In addition to the DTCs, the response also includes status information for each code.

03. 0x03 – ReportDTCSnapshotIdentification: This function provides information about available snapshot records. Snapshot data includes sensor values or operational conditions captured when the fault occurred.

04. 0x04 – ReportDTCSnapshotRecordByDTCNumber: Retrieves snapshot data associated with a specific DTC. This is critical for reproducing the condition under which a fault occurred.

05. 0x05 – ReportDTCSnapshotRecordByRecordNumber: Similar to 0x04 but retrieves data based on a predefined record number instead of the DTC itself.

06. 0x06 – ReportDTCExtendedDataRecordByDTCNumber: Returns extended data records for a specific DTC. Extended data may include counters, timers, and internal state values that are helpful for advanced diagnostics.

07. 0x07 – ReportNumberOfDTCBySeverityMaskRecord: Returns the number of DTCs matching a specified severity mask. This helps in determining how critical the active faults are.

08. 0x08 – ReportDTCBySeverityMaskRecord: Returns actual DTCs that match a given severity mask, along with their severity and functional failure types.

09. 0x09 – ReportSeverityInformationOfDTC: Provides detailed severity information of a particular DTC. Useful for prioritizing repairs based on impact.

10. 0x0A – ReportSupportedDTC: Returns a list of all DTCs that the ECU supports, regardless of whether they are currently active.

11. 0x0B – ReportFirstTestFailedDTC: Returns the first DTC that failed during the current operation cycle.

12. 0x0C – ReportFirstConfirmedDTC: Returns the first confirmed DTC that met confirmation criteria (e.g., failed multiple times).

13. 0x0D – ReportMostRecentTestFailedDTC: Returns the most recent DTC that failed.

14. 0x0E – ReportMostRecentConfirmedDTC: Returns the most recent confirmed DTC.

15. 0x0F – ReportMirrorMemoryDTCByStatusMask: Returns DTCs stored in mirror memory, a separate memory area used for certain types of diagnostics.

16. 0x10 – ReportMirrorMemoryDTCExtendedDataRecordByDTCNumber: Retrieves extended data for DTCs stored in mirror memory.

17. 0x11 – ReportNumberOfMirrorMemoryDTCByStatusMask: Returns the count of DTCs in mirror memory matching a specific status mask.

18. 0x12 – ReportNumberOfEmissionsRelatedOBDDTCByStatusMask: Reports the number of emissions-related DTCs based on a status mask. Crucial for OBD compliance.

19. 0x13 – ReportEmissionsRelatedOBDDTCByStatusMask: Returns actual emissions-related DTCs matching a status mask.

20. 0x14 – ReportDTCFaultDetectionCounter: Returns the fault detection counter value for a specific DTC. It helps determine how many times the fault condition has occurred.

Explanation of Status Byte

The DTC Status Byte is an 8-bit field used to indicate the condition of a DTC. Each bit has a specific meaning:

- Bit 0 (testFailed) – Indicates that the diagnostic test has failed.

- Bit 1 (testFailedThisOperationCycle) – The test failed during the current driving cycle.

- Bit 2 (pendingDTC) – The fault has been detected but not yet confirmed.

- Bit 3 (confirmedDTC) – The fault has been confirmed and stored.

- Bit 4 (testNotCompletedSinceLastClear) – Indicates the test has not been completed since the last DTC clear.

- Bit 5 (testFailedSinceLastClear) – Shows that the test has failed since the last DTC clear.

- Bit 6 (testNotCompletedThisOperationCycle) – Indicates the test has not run in the current cycle.

- Bit 7 (warningIndicatorRequested) – The ECU has requested the MIL (Malfunction Indicator Lamp) to be turned on.

The status byte allows the tester to determine the current condition and diagnostic history of each DTC.

UDS Request and Response

Here’s the UDS request and response example for reading the DTC status byte showing warningIndicatorRequested (Bit 7 = 1), using Service 0x19 (ReadDTCInformation) with Sub-function 0x02 (Report DTC by Status Mask):

? Request: You want to read all DTCs where warningIndicatorRequested = 1, which is Bit 7 of the status byte.

[0x19][0x02][0x80]

Breakdown:

- 0x19 → ReadDTCInformation (service ID)

- 0x02 → ReportDTCByStatusMask (sub-function)

- 0x80 → Status mask: Bit 7 set (10000000), filter for DTCs with MIL ON

? Response (Example for DTC P0420):

[0x59][0x02][0x01][0xP0][0x42][0x0][0x90]

Breakdown:

- 0x59 → Positive response to service 0x19

- 0x02 → Echo of sub-function

- 0x01 → Number of DTCs = 1

- 0xP0 0x42 0x0 → DTC code: P0420 (DTCs are usually encoded in 3 bytes)

- 0x90 → DTC Status Byte: 10010000

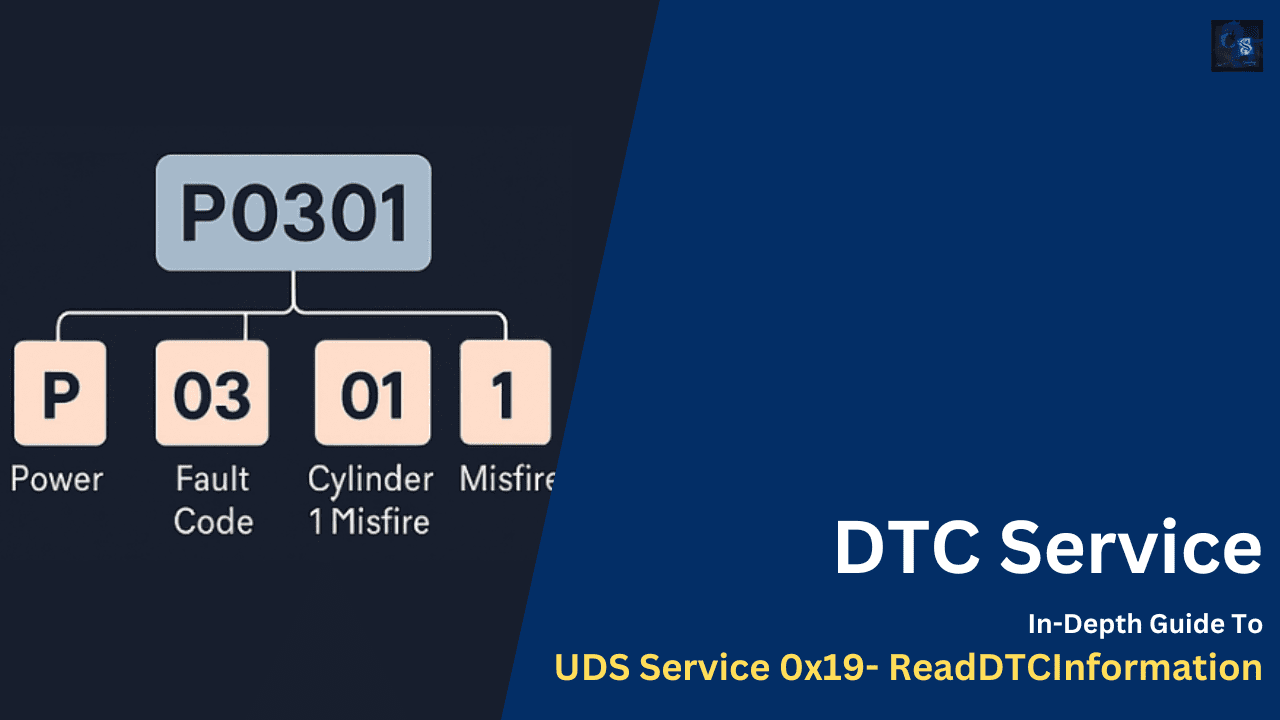

Real-World Example: P0301

DTC Code: P0301

- P: Powertrain

- 0: SAE (Generic DTC)

- 3: Ignition System or Misfire

- 01: Cylinder 1 Misfire

Meaning:

- This code means that the ECU detected a misfire in Cylinder 1.

Possible Causes:

- A faulty spark plug in cylinder 1

- Bad ignition coil

- Fuel injector failure

- Vacuum leak

- Low compression

Snapshot Record: The ECU may record:

- Engine speed (RPM)

- Load value

- Coolant temperature

- Throttle position

Extended Data:

- Misfire counters

- Time since last fault

- Number of drive cycles since confirmed

Status Byte:

- Bit 0: 1 (test failed)

- Bit 1: 1 (test failed this cycle)

- Bit 3: 1 (confirmed)

- Bit 7: 1 (MIL requested)

This allows technicians to understand the severity, frequency, and conditions under which the misfire occurred.

Use Cases of Service 0x19

- During Vehicle Development: Engineers use snapshot and extended data to debug new vehicle software and calibration issues.

- At Workshops: Service technicians read DTCs and fix root causes efficiently.

- During Inspection & Certification: Regulatory bodies inspect emissions-related DTCs.

- Telematics & Fleet Diagnostics: Remote DTC reading for predictive maintenance.

Diagnostic Trouble Code (DTC) Format

A typical DTC is represented as a 5-character alphanumeric string (e.g., P0301):

1st Character (System):

- P: Powertrain

- B: Body

- C: Chassis

- U: Network

2nd Character (Code Type):

- 0: SAE (Generic)

- 1: Manufacturer Specific

3rd Character (Subsystem):

- 1: Fuel & Air Metering

- 2: Fuel & Air Metering (Injector Circuit)

- 3: Ignition System

- 4: Emissions System

- 5: Speed Control & Idle

Last Two Digits: Specific fault code

Memory Types in ECUs for DTC Storage

- Primary Memory: Stores active and historic DTCs

- Mirror Memory: Stores the last known DTCs even after a reset

- Non-volatile Memory: Keeps confirmed DTCs across power cycles

Fault Detection Logic

Each DTC is associated with detection logic:

- Fault condition check

- Confirmation logic (e.g., must fail X times)

- MIL request logic

This logic ensures only valid and repeatable faults are stored.

Functional Failure Types

Each DTC may be associated with a failure type, like:

- General electrical failure

- Short to ground or battery

- Mechanical failure

- Calibration or performance issue

These are included in extended records.

Integration with Other UDS Services

- Service 0x14 (ClearDiagnosticInformation) – Used to clear DTCs

- Service 0x22 (ReadDataByIdentifier) – To read sensor/actuator status

- Service 0x27 (SecurityAccess) – Some DTCs require unlock access

- Service 0x2F (InputOutputControlByIdentifier) – Used to simulate conditions

Best Practices

- Always check the status byte before clearing DTCs

- Use snapshot and extended data to support root cause analysis

- Follow OBD regulations for emissions-related DTC handling

- Do not clear DTCs during active failures—it may mask issues

Summary

UDS Service 0x19 is a cornerstone of automotive diagnostics. With its many sub-functions, it allows detailed fault reporting, root cause analysis, and regulatory compliance. Understanding its sub-functions, status byte, and practical use cases is critical for engineers and technicians.

From simple fault reading to advanced diagnostics like snapshot and extended data interpretation, Service 0x19 bridges the gap between raw data and actionable insight. Whether you are debugging an ECU, servicing a vehicle, or designing diagnostics infrastructure, mastering Service 0x19 is essential.

This was about “In-Depth Guide To UDS Service 0x19 – ReadDTCInformation“. Thank you for reading.

Also, read:

- FlexRay Protocol – Deep Visual Technical Guide

- Top 50 AI-Based Projects for Electronics Engineers

- UDS (Unified Diagnostic Services) — Deep Visual Technical Guide

- Automotive Ethernet — Deep Visual Technical Guide

- Controller Area Network (CAN) — Deep Visual Technical Guide

- Top 30 High-Paying Embedded Tools You Must Learn in 2026

- Automotive Resource For Free On GitHub

- When Technology Fails: How a Trapped EV Crash Changed Car Safety in China