Model-Based Development (MBD) In Automotive: From Simulink To Production Code

Hello guys, welcome back to our blog. Here in this article, I will discuss model-based development (MBD) on automotive and how the flow goes from Simulink to production code.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Battery State Estimation: SOC, SOH, SOP, SoE, SoF And How They Impact EV Performance

- Top 50 Advance-Level MiL, SiL, PiL, HiL, DiL, ViL Interview Questions

- Top 50 Advance-Level MATLAB Simulink Interview Questions

Model-Based Development (MBD) In Automotive

The automotive industry has rapidly evolved with the integration of advanced control systems and embedded technologies. Model-Based Development (MBD) has emerged as a critical approach for designing, testing, and deploying automotive control algorithms efficiently. This article explores how MATLAB/Simulink facilitates MBD, with a primary focus on the transition from Simulink models to production-ready embedded C code.

Overview of Model-Based Development (MBD)

Model-Based Development (MBD) is a systematic approach to developing embedded systems using graphical models instead of traditional hand-written code. It allows engineers to design, simulate, test, and automatically generate production-ready code, significantly reducing development time and improving reliability.

Importance of MBD in Automotive

- Reduces development and testing time

- Enhances design accuracy with simulation and validation

- Enables early detection of design flaws

- Facilitates automatic code generation, reducing manual coding errors

Simulink for Automotive Control Algorithm Design

MATLAB/Simulink provides a robust environment for designing automotive control algorithms. Engineers use Simulink to create dynamic models of vehicle systems and test their behavior before implementing them in real hardware.

Simulink Basics

- Block Diagram Representation: Models are created using interconnected blocks representing mathematical functions and logic.

- Data Flow Control: Execution of signals across different subsystems.

- Parameterization: Real-time tuning of parameters for optimization.

Transition from Simulink to Production Code

The core of Model-Based Development is the ability to transition seamlessly from Simulink models to production-ready embedded C code.

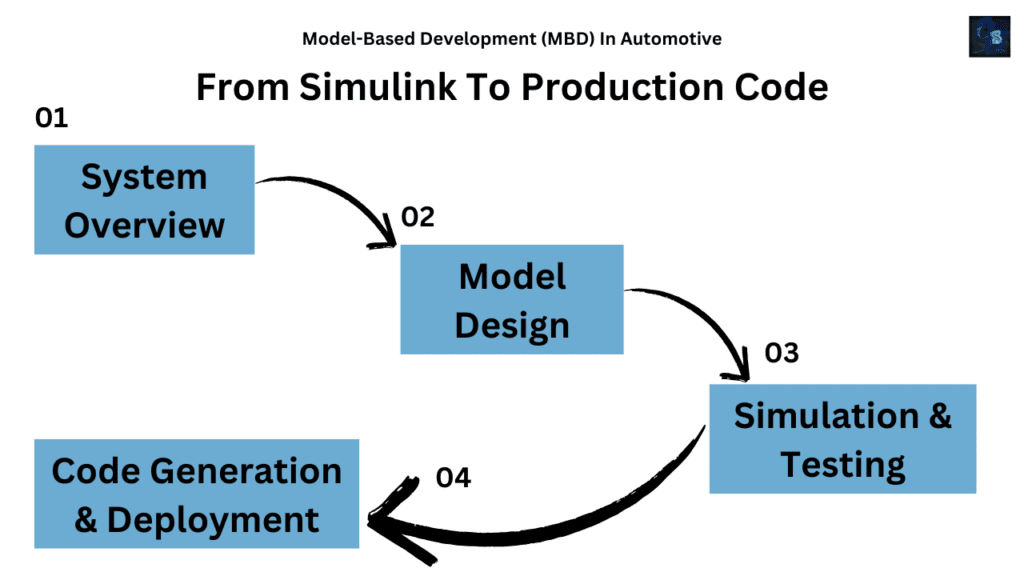

Steps in Code Generation

- Model Configuration in Simulink: Define the control logic and parameters required for production.

- Code Generation using Embedded Coder: Convert Simulink models into structured, efficient C code.

- Code Optimization and Validation: Ensure compliance with automotive standards such as MISRA C.

- Integration into ECU Software: Deploy and validate the generated code within the vehicle’s electronic control unit (ECU).

Embedded Coder for Production Code

MATLAB’s Embedded Coder is the primary tool for generating production code from Simulink models. Key features include:

- Highly optimized C code generation for embedded processors

- AUTOSAR compatibility for seamless automotive software integration

- MISRA C compliance for safety-critical applications

- Code traceability from model to generated code

Simulation & Testing Before Deployment

- Model-in-the-Loop (MiL): Ensuring functional correctness at the model level.

- Software-in-the-Loop (SiL): Verifying the auto-generated C code within a software simulation.

- Processor-in-the-Loop (PiL): Validating execution on the target microcontroller.

- Hardware-in-the-Loop (HiL): Testing the code on real automotive hardware.

Real-Time Testing and Deployment

Once the production code is generated, it is integrated into ECUs for real-time validation.

Rapid Control Prototyping (RCP)

- Allows engineers to test control strategies using real hardware before finalizing the design.

Hardware Testing and Debugging

- Integration with real sensors and actuators

- Debugging using tools like dSPACE, ETAS, and Vector CANoe

Case Study: MBD Implementation in an Electric Vehicle

System Overview

- Design of a battery management system (BMS) for an electric vehicle (EV)

- Use of MATLAB/Simulink for SOC estimation and thermal management

Model Design

- Development of mathematical models for battery dynamics

- Implementation of fault detection algorithms

Simulation & Testing

- MiL and HiL validation before deploying the code to the ECU

Code Generation & Deployment

- Automatic C code generation using Embedded Coder

- Deployment on a real BMS controller

Future of MBD in Automotive

- Integration with AI and machine learning for predictive control

- Cloud-based simulation and testing

- Enhanced cybersecurity for connected vehicles

Conclusion

Model-Based Development (MBD) using MATLAB/Simulink has revolutionized automotive software development. The transition from Simulink models to production-ready C code through Embedded Coder ensures high reliability and efficiency in automotive control systems. As the industry moves towards autonomous and electrified vehicles, MBD will play an even more critical role in shaping the future of automotive technology.

This was about “Model-Based Development (MBD) In Automotive: From Simulink To Production Code”. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?

- Advanced Driver Assistance Systems (ADAS): How To Become An Expert In This Growing Field