On-Board Diagnostics (OBD) – A Complete Tutorial

Hello guys, welcome back to our blog. In this article, we will explore onboard diagnostics, different OBD services, and how to get started with onboard diagnostics.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- All-Wheel Drive (AWD) Vs Front-Wheel Drive (FWD) Vs Rear-Wheel Drive (RWD): Which Is Better?

- CAPL Scripting Tutorial For Automotive Engineers

- MiL, SiL, PiL, HiL, DiL, And ViL Testing Methods In Automotive

On-Board Diagnostics (OBD)

On-Board Diagnostics (OBD) is a standardized system used in vehicles to monitor and report engine performance, emissions, and system health. OBD systems help diagnose faults in the vehicle by storing Diagnostic Trouble Codes (DTCs) when an issue is detected.

OBD has evolved over time, with OBD-I being the first version (before 1996) and OBD-II (since 1996) becoming the standard in most vehicles worldwide.

Evolution of OBD Systems

| Version | Key Features |

| OBD-I | Manufacturer-specific, limited diagnostic capabilities. |

| OBD-II | Standardized protocols, support for real-time monitoring, and enhanced diagnostics. |

| EOBD | European equivalent of OBD-II, mandatory for petrol cars (since 2001) and diesel cars (since 2004). |

| JOBD | Japanese version of OBD-II. |

| UDS (Unified Diagnostic Services) | Advanced diagnostic protocol used in modern vehicles. |

OBD Communication Protocols

OBD-II systems use different communication protocols, including:

- SAE J1850 PWM (Pulse Width Modulation) – Used by Ford.

- SAE J1850 VPW (Variable Pulse Width) – Used by GM.

- ISO 9141-2 – Used in older European and Asian cars.

- ISO 14230 (KWP2000 – Keyword Protocol 2000) – Used in some European and Asian cars.

- ISO 15765-4 (CAN – Controller Area Network) – Used in all modern vehicles after 2008.

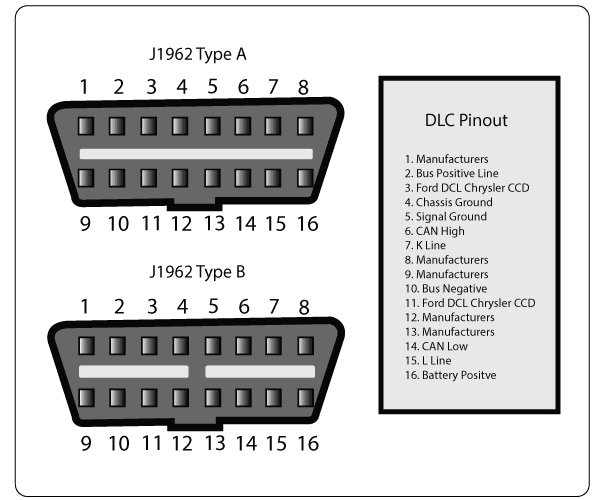

OBD-II Connector (DLC – Data Link Connector)

The OBD-II connector is a 16-pin interface, usually located under the dashboard near the driver’s seat.

| Pin | Function |

| 4 & 5 | Ground |

| 6 & 14 | CAN High & Low |

| 7 & 15 | K-Line (ISO 9141-2, KWP2000) |

| 16 | Battery Power |

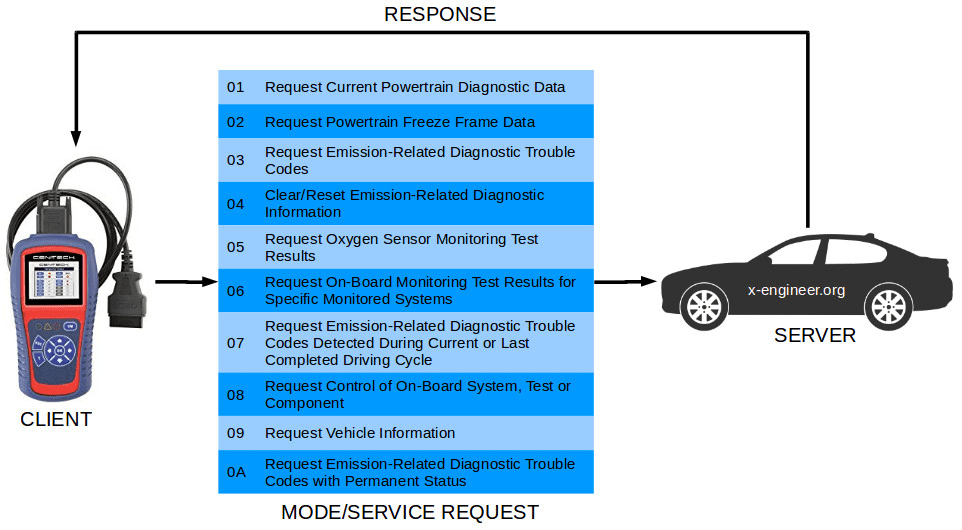

OBD-II Services (Modes)

OBD-II defines 10 diagnostic services (also known as modes). These are used to request vehicle data.

Service Mode 01: Request Current Powertrain Data

- Retrieves real-time data like engine RPM, vehicle speed, coolant temperature, fuel system status, etc.

- Example PID (Parameter IDs):

- Engine RPM: 010C

- Vehicle Speed: 010D

- Coolant Temperature: 0105

Service Mode 02: Request Freeze Frame Data

- Captures vehicle conditions at the time a fault occurs.

- Data includes engine speed, throttle position, and temperature at fault occurrence.

Service Mode 03: Request Stored Diagnostic Trouble Codes (DTCs)

- Reads the trouble codes stored in the ECU.

- Example DTC: P0300 (Random Misfire Detected).

Service Mode 04: Clear DTCs and Reset MIL (Malfunction Indicator Lamp)

- Erases stored trouble codes and resets the Check Engine Light (CEL).

- Used after repairs.

Service Mode 05: Request Oxygen Sensor Test Results

- Retrieves O2 sensor test results for emissions monitoring.

- Ensures the catalytic converter is functioning properly.

Service Mode 06: Request On-Board Monitoring Test Results

- Provides test results for systems like misfire detection, fuel system monitoring, and EGR system monitoring.

Service Mode 07: Request Pending DTCs

- Retrieves trouble codes that are not yet confirmed but could lead to a fault.

Service Mode 08: Request Control of On-Board Systems

- Allows actuation of specific vehicle components (e.g., turning the cooling fan on/off).

Service Mode 09: Request Vehicle Information

- Retrieves the How to Read OBD Data?VIN (Vehicle Identification Number), calibration ID, and ECU software versions.

Service Mode 0A: Request Permanent DTCs

- Retrieves permanent trouble codes that cannot be erased until the issue is resolved.

How to Read OBD Data?

To read OBD-II data, you need an OBD-II scanner or diagnostic tool, which can be:

- Handheld OBD-II scanners

- Bluetooth/Wi-Fi OBD-II adapters (used with mobile apps)

- Professional diagnostic tools like Bosch, Autel, and Launch

Common OBD-II Trouble Codes (DTCs)

| Code | Meaning |

| P0101 | Mass Airflow Sensor Issue |

| P0300 | Random/Multiple Cylinder Misfire |

| P0420 | Catalyst System Efficiency Below Threshold |

| P0500 | Vehicle Speed Sensor Malfunction |

| P0700 | Transmission Control System Malfunction |

OBD and Vehicle Emissions

OBD-II plays a crucial role in emission control by:

- Monitoring catalytic converters and oxygen sensors.

- Ensuring fuel system efficiency.

- Detecting EVAP (Evaporative Emission Control) leaks.

Future of OBD (OBD-III and Beyond)

Future advancements in OBD include:

- Remote diagnostics using cloud-based OBD-III.

- Over-the-air (OTA) updates for vehicle software.

- Integration with ADAS and autonomous driving systems.

OBD-II is an essential system for vehicle diagnostics, emissions monitoring, and performance optimization. Understanding its communication protocols, services, and diagnostic trouble codes helps in efficient vehicle maintenance and troubleshooting.

This was about “On-Board Diagnostics (OBD) – A Complete Tutorial“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?