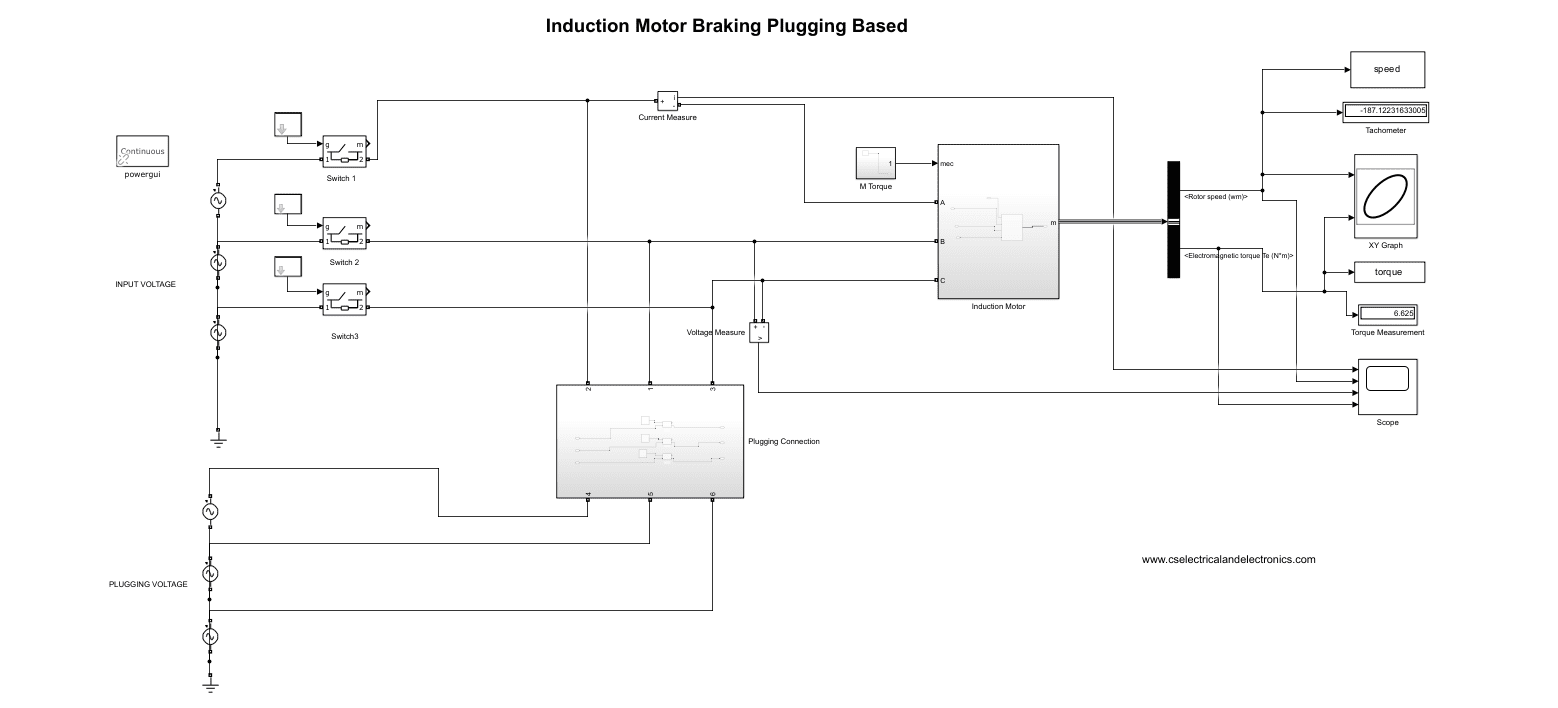

Induction Motor Braking Plugging Based In MATLAB Simulink

Description

This price is for Indians, if you are from another country then your model price will be different it depends on your country’s currency- Chat with us on WhatsApp.

Hello guys, in this zip file, you will find the Matlab Simulink model on the Plugging-based braking of the Induction motor.

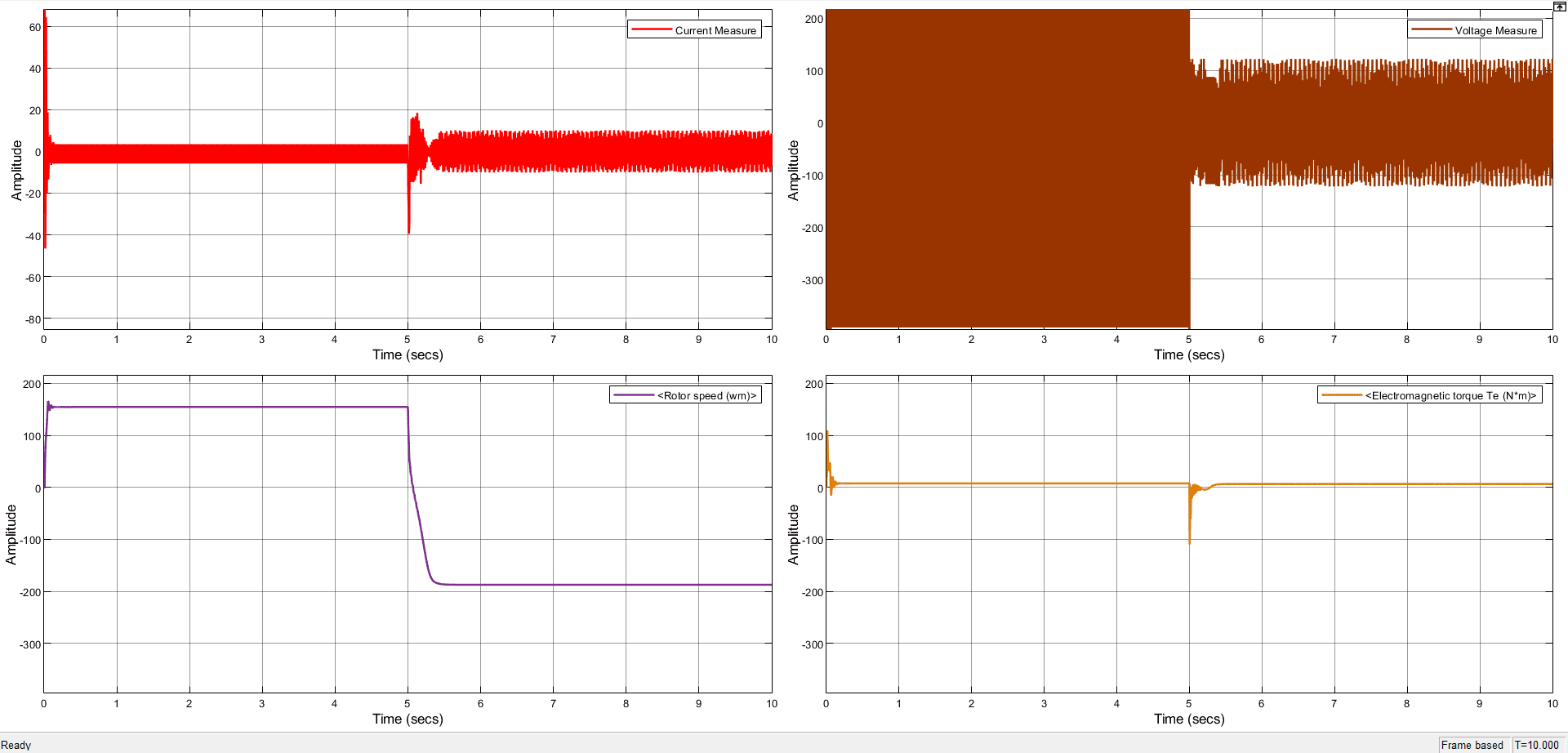

Induction motors can be stopped by plugging by rotating them in the opposite direction. This is accomplished by switching the supply voltage’s polarity to the motor’s windings, which causes the magnetic field to flip and the motor to halt abruptly.

In applications like conveyor belts or cranes where the motor is employed for irregular or cyclical actions, plugging is most frequently used. To avoid accidents or equipment damage in these situations, it’s crucial to rapidly and safely bring the motor to a stop.

The motor must first be unplugged from the power source before the supply voltage may be switched by switching the motor’s terminals. As a result, the motor starts to function as a generator and generates a reverse torque that slows the motor down and causes it to halt.

One benefit of plugging is that it can enable rapid deceleration rates and quickly bring the motor to a stop. It can also be utilized to regulate the motor’s speed while stopping.

The protection of the motor and the driven load is a crucial factor to take into account while employing plugging. If the braking process is not adequately regulated, plugging can result in mechanical strains on both the motor and the load, which may cause damage or failure. It is crucial to employ a soft-start circuit to progressively lower the motor’s speed before implementing the plugging operation in order to mitigate this. This increases the system’s safety and dependability by lowering the mechanical stress on the load and the motor.

Another drawback of plugging is that it can result in significant inrush currents when the engine is started up again after braking. The windings of the motor or other system components may be harmed as a result.

This can be reduced by adding a current-limiting component to the circuit, such as a resistor or a reactor, which will reduce the inrush current and safeguard the motor.

Because it takes time for the braking process to reverse the direction of the motor’s spin, plugging is not appropriate for applications where the motor needs to be stopped rapidly and then restarted right away. Other braking techniques, such as dynamic or regenerative braking, may be more appropriate for these purposes.

In conclusion, plugging is a useful technique for stopping induction motors in intermittent or cyclic applications. It is capable of delivering rapid deceleration rates and quickly stopping the motor. Other braking techniques should be taken into consideration for continuous or high-power applications since it demands careful design and control to assure safe and reliable operation.

Disclaimer:

Please note, that this product is owned by us, and if you upload this file on Youtube or the Internet after purchasing it. Then you will get a copyright complaint from us.

Thanks & regards,

CS Electrical And Electronics Team

Chat Us On WhatsApp For Support: Click Here