Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer

Hello guys, welcome back to our blog. In this article, I will discuss the roadmap to become a successful hardware-in-the-loop (HiL) engineer, why MiL testing is very important, and the skills required to become a HiL engineer.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- 1000+ Automotive Interview Questions With Answers

- RTOS In The Automotive Industry: The Brains Behind Real-Time Vehicle Control

- High Performance Computers in Software-Defined Vehicles (SDVs): Architecture, Challenges, and Future Trends

Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer

The automotive industry is rapidly evolving with the integration of advanced electronics, autonomous systems, and safety-critical features. As these systems become more complex, traditional testing methods are no longer sufficient. Enter Hardware-in-the-Loop (HiL) — a technique that allows testing embedded systems in a simulated real-time environment. A HiL Engineer plays a crucial role in ensuring the reliability, safety, and performance of embedded systems before physical deployment.

What is Hardware-in-the-Loop (HiL)?

HiL Simulation is a method of testing real-time embedded systems by simulating physical components using software models. Instead of connecting the ECU (Electronic Control Unit) to a real vehicle or hardware, it is connected to a simulation environment that mimics the real world.

Key Components:

- HiL Simulator

- Real-Time Plant Models

- ECU or DUT (Device Under Test)

- I/O Interface Boards

- Test Automation Framework

Why is HiL Testing Important?

- Reduces development costs and time

- Ensures safety before real-world testing

- Enables validation in edge-case scenarios

- Facilitates regression and stress testing

- Essential for ISO 26262 safety compliance

Industries Using HiL Simulation

- Automotive (ADAS, Powertrain, Body Control)

- Aerospace (Flight Control Systems)

- Railways (Train Control & Monitoring)

- Industrial Automation

- Robotics

- Medical Devices

Educational Qualifications

Preferred Backgrounds:

B.E/B.Tech or M.E/M.Tech in:

- Electrical/Electronics Engineering

- Mechatronics

- Instrumentation

- Automotive Engineering

- Computer Science (with embedded electives)

Basic Subjects to Master:

- Control Systems

- Embedded Systems

- Signal Processing

- Vehicle Dynamics (for automotive)

- Power Electronics

Essential Skills for HiL Engineers

| Domain | Skills |

| Programming | C, C++, Python, MATLAB |

| Modeling | Simulink, Stateflow |

| Communication Protocols | CAN, LIN, FlexRay, Ethernet, UDS |

| Tools | dSPACE, NI VeriStand, Vector CANoe, ETAS LABCAR |

| Test Automation | CAPL, Python, AutomationDesk |

| Scripting | Bash, PowerShell |

| Electrical | Circuit Design, Signal Conditioning |

| Soft Skills | Problem-solving, Communication, Documentation |

Tools and Technologies to Master

| Tool | Use |

| dSPACE | Plant model simulation, ControlDesk |

| Vector CANoe/CANalyzer | Bus simulation, diagnostics |

| ETAS LABCAR | HiL simulation & automation |

| NI | VeriStand/LabVIEW Real-time testing & automation |

| Simulink/Stateflow | Model creation, test cases |

| Python/CAPL | Test scripting |

| VM/RTOS | Real-time test environments |

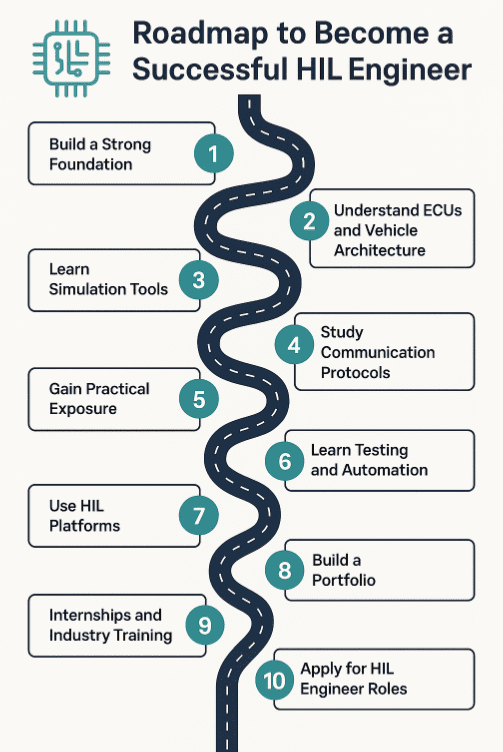

Step-by-Step Roadmap to Become a HiL Engineer

Step 1: Build a Strong Foundation

- Learn control systems, real-time systems, and embedded C

- Get hands-on with Arduino, Raspberry Pi for hardware interfacing

Step 2: Understand ECUs and Vehicle Architecture

- Study types of ECUs (Powertrain, ADAS, Body Control)

- Learn about sensors, actuators, and signal conditioning

Step 3: Learn Simulation Tools

- Master MATLAB/Simulink and build simple plant models

- Learn Stateflow for logic-based control

Step 4: Study Communication Protocols

- Understand CAN, LIN, UDS, and how diagnostic services work

Step 5: Gain Practical Exposure

- Work on projects that simulate a HiL environment (e.g., DC motor simulation, vehicle lighting control)

Step 6: Learn Testing and Automation

- Practice writing CAPL and Python test scripts

- Explore tools like CANoe, CANalyzer, and AutomationDesk

Step 7: Use HiL Platforms

- Gain hands-on experience with dSPACE, NI PXI, or ETAS simulators

- Study how to configure the test bench, I/O mapping, and fault injection

Step 8: Build a Portfolio

- Document mini-projects (Simulink models, ECU testing, etc.)

- Create a GitHub repository or personal website

Step 9: Internships and Industry Training

- Apply for internships in OEMs and Tier-1s

- Take certified training programs (dSPACE, Vector, NI)

Step 10: Apply for HiL Engineer Roles

- Tailor your resume with tools, projects, and certifications

- Prepare for interviews (more on this below)

Certifications to Boost Your Career

- ISO 26262 – Functional Safety

- Vector CANoe & CAPL Training

- dSPACE TargetLink or AutomationDesk Training

- NI LabVIEW Certification (CLAD/CLD)

- MathWorks Simulink & Stateflow Certification

- ASAM XIL Standard Familiarity

Real-Time Operating Systems (RTOS) in HiL

Many HiL systems simulate real-time conditions. Understanding RTOS like VxWorks, FreeRTOS, or QNX is beneficial for advanced roles.

Why Learn RTOS?

- Real-time scheduling of tasks

- Deterministic behavior

- Parallel test execution

Typical Interview Topics

| Category | Questions |

| Basics | What is HiL? Why not just test in the vehicle? |

| Tools | How do you configure dSPACE/ETAS? |

| Protocols | Explain UDS service 0x22, 0x2E, 0x19 |

| CAPL | Write a script to simulate an ECU on CAN |

| Simulink | Difference between Normal, Accelerator, and SIL modes |

| Automation | How do you trigger fault injection in AutomationDesk? |

| RT | How do you ensure real-time behavior of your system? |

Common Challenges in HiL Projects

- Signal mismatch between the ECU and the simulator

- Timing synchronization errors

- Model instability or divergence

- High latency in test execution

- Debugging test cases due to closed-loop failure

Career Path and Growth Opportunities

| Role | Experience |

| Junior HiL Engineer | 0–2 years |

| HiL Test Engineer | 2–5 years |

| HiL Architect | 5–8 years |

| HiL Lead/Test Manager | 8–12 years |

| System Validation Lead | 10+ years |

You can also pivot into:

- Model-Based Design

- Embedded Software

- System Integration

- Functional Safety Engineering

Tips to Stay Updated

- Follow SAE, IEEE, and AUTOSAR publications

- Join LinkedIn groups for HiL and Automotive Testing

- Attend conferences like Embedded World, dSPACE Conference, and NI Week

- Take online courses (Udemy, Coursera, MathWorks)

Conclusion

Becoming a successful HiL Engineer requires a combination of domain knowledge, software skills, and hardware interfacing. With vehicles becoming software-defined, the need for robust system validation is at an all-time high. By following the structured roadmap above, you can position yourself as a competent, industry-ready HiL Engineer, ready to solve real-world challenges in automotive and beyond.

This was about “Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?