Software-Defined Vehicles Development Lifecycle: Part 05

Hello guys, welcome back to our blog. In this article, I will discuss the software-defined vehicles development lifecycle, I will cover terms like design methods, tools, and testing methods.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Software-Defined Vehicles Enabling Technologies: Part 04

- Core Software Layers In Software Defined Vehicles: Part 03

- Software-defined Vehicle Architecture: Part 02

Software-Defined Vehicles Development Lifecycle

The Software-Defined Vehicle (SDV) represents a new paradigm in vehicle development. Traditional automotive development—often rigid, hardware-bound, and sequential—is being replaced by agile, iterative, and software-centric practices. This shift mandates not just new tools, but an entire rethinking of the vehicle development lifecycle.

The SDV development lifecycle focuses on continuous software improvement, early integration, and extensive testing across the digital spectrum. Central to this transformation are practices like Continuous Integration/Continuous Deployment (CI/CD), DevOps, model-based development, virtualization through virtual ECUs, and rigorous testing strategies like MiL, SiL, and HiL. All these are powered by industry-leading toolchains and platforms.

CI/CD and DevOps in Automotive

CI/CD Overview

Continuous Integration (CI) and Continuous Deployment (CD) are essential elements of modern software engineering, enabling rapid iteration and feedback. In the SDV context, CI/CD pipelines automate the integration of code, build processes, software validation, and deployment. This allows teams to push frequent updates with minimal human intervention.

For example, when a developer commits new ADAS logic or infotainment feature code, the CI server automatically builds the firmware, performs static checks, unit tests, and deploys it to a test environment. These updates can then be delivered Over-The-Air (OTA) or to HiL rigs for validation.

DevOps Adaptation in SDV

DevOps in SDVs bridges development (Dev) and operations (Ops) through automation, collaboration, and monitoring. While traditional automotive workflows follow the V-cycle, SDVs require a more fluid approach:

- Automated Builds and Regression Tests: Rapid identification of issues.

- OTA Deployment Simulations: Testing update mechanisms pre-release.

- Containerized Microservices: For deploying infotainment, V2X, or diagnostics modules.

- Monitoring and Telemetry: In-vehicle data helps guide future software updates.

Challenges & Benefits

- Challenges: Integrating with legacy V-model practices, ensuring real-time constraints, and safety-critical update validation.

- Benefits: Faster release cycles, enhanced collaboration between teams, and a software-centric approach aligned with user demands.

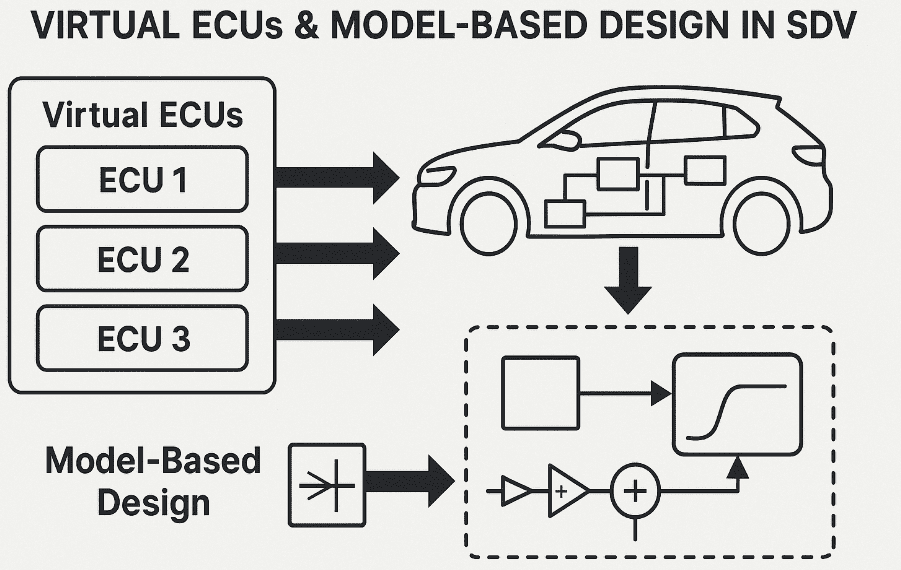

Virtual ECUs & Model-Based Design

Virtual ECUs (vECUs)

Virtual ECUs represent the abstraction of traditional ECUs into software running on desktops or cloud environments. These can simulate the behavior of actual ECUs without needing physical hardware.

Types of Virtual ECUs:

- Functional Mock-ups: To validate functional logic early in development.

- System-level vECUs: For integration and network testing.

- Cloud-hosted vECUs: Scalable testing at scale using container orchestration (e.g., Kubernetes).

Benefits:

- Test early, test often—even before hardware is ready.

- Cost-effective and scalable.

- Enable CI pipelines to run ECU tests without hardware-in-the-loop.

Model-Based Design (MBD)

Model-Based Design revolutionizes embedded development by allowing engineers to design systems using graphical models (like in Simulink or Scade). It involves:

- System Specification via Models

- Automatic Code Generation

- Simulation & Verification at Design-Time

MBD Advantages in SDV:

- Early error detection via simulation.

- Formal validation of safety and control logic.

- Enables the reuse of models across variants.

Together, vECUs and MBD enable front-loading of testing, reducing costs and shortening development time.

Testing Methods: MiL, SiL, HiL

Rigorous validation is critical in SDVs, especially for safety and compliance. Here’s how the three-tier testing hierarchy works:

Model-in-the-Loop (MiL)

MiL involves simulating control algorithms and plant models in a virtual environment. This is the earliest testing stage, used to validate system logic before any code is generated.

- Tools: MATLAB/Simulink, Stateflow, CarMaker

- Use Case: Verifying sensor fusion algorithms in ADAS.

Software-in-the-Loop (SiL)

SiL moves closer to reality by testing the generated C code from the model in a PC-based environment. It validates code logic and behavior against models.

- Tools: MATLAB, Eclipse-based IDEs, Custom PCs

- Use Case: Checking control logic performance or failure conditions.

Hardware-in-the-Loop (HiL)

HiL tests involve real control units connected to simulated vehicle environments. It’s the final testbed before in-vehicle trials.

- Tools: dSPACE, ETAS, NI VeriStand

- Use Case: Validating ABS ECU behavior under various driving conditions.

Each method provides value at a different stage—reducing risk, catching bugs early, and validating real-world readiness.

Tools: Vector, ETAS, dSPACE, MATLAB/Simulink

SDV development wouldn’t be possible without sophisticated toolchains. Here are some industry-leading platforms:

Vector Informatik

- CANoe: Network simulation, diagnostics, and ECU testing.

- CAPL Scripting: For simulating real-world vehicle scenarios.

- vVIRTUALtarget: For virtual ECU testing.

Use Cases: Network validation, diagnostics, ADAS testing.

ETAS (by Bosch)

- INCA: Measurement, calibration, and diagnostics.

- ISOLAR-A/B: AUTOSAR-compliant ECU design and code generation.

- LABCAR: HiL testing systems.

Use Cases: Embedded control systems, real-time ECU testing, and AUTOSAR architecture.

dSPACE

- ControlDesk & SCALEXIO: Real-time HiL and rapid prototyping.

- VEOS: For virtual validation.

- TargetLink: Code generation from MATLAB models.

Use Cases: ECU prototyping, real-time systems, vehicle dynamics.

MATLAB/Simulink

- Simulink: Model-based design for control algorithms.

- Stateflow: Logic-driven systems.

- Simscape/Vehicle Dynamics Toolbox: For modeling powertrains, chassis, and electrical networks.

Use Cases: MiL/SiL testing, algorithm design, plant modeling.

These tools are often integrated with DevOps pipelines, cloud simulators, and AI-driven optimization techniques to form a complete SDV toolchain ecosystem.

Conclusion: SDV Development Lifecycle

The SDV development lifecycle is dynamic, digital, and deeply rooted in software practices. By integrating CI/CD and DevOps, manufacturers can update vehicle features in near real-time. Virtual ECUs and model-based design help identify issues earlier in the process, significantly reducing time-to-market.

Meanwhile, the testing triangle—MiL, SiL, and HiL—ensures every component is validated against real-world constraints before deployment. The reliance on sophisticated tools like Vector, ETAS, dSPACE, and MATLAB/Simulink enables high-fidelity simulation and testing across every development phase.

As vehicles become platforms of continuous innovation, mastering this lifecycle is not just an advantage—it’s a necessity for OEMs, suppliers, and developers.

This was about “Software-Defined Vehicles Development Lifecycle“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?