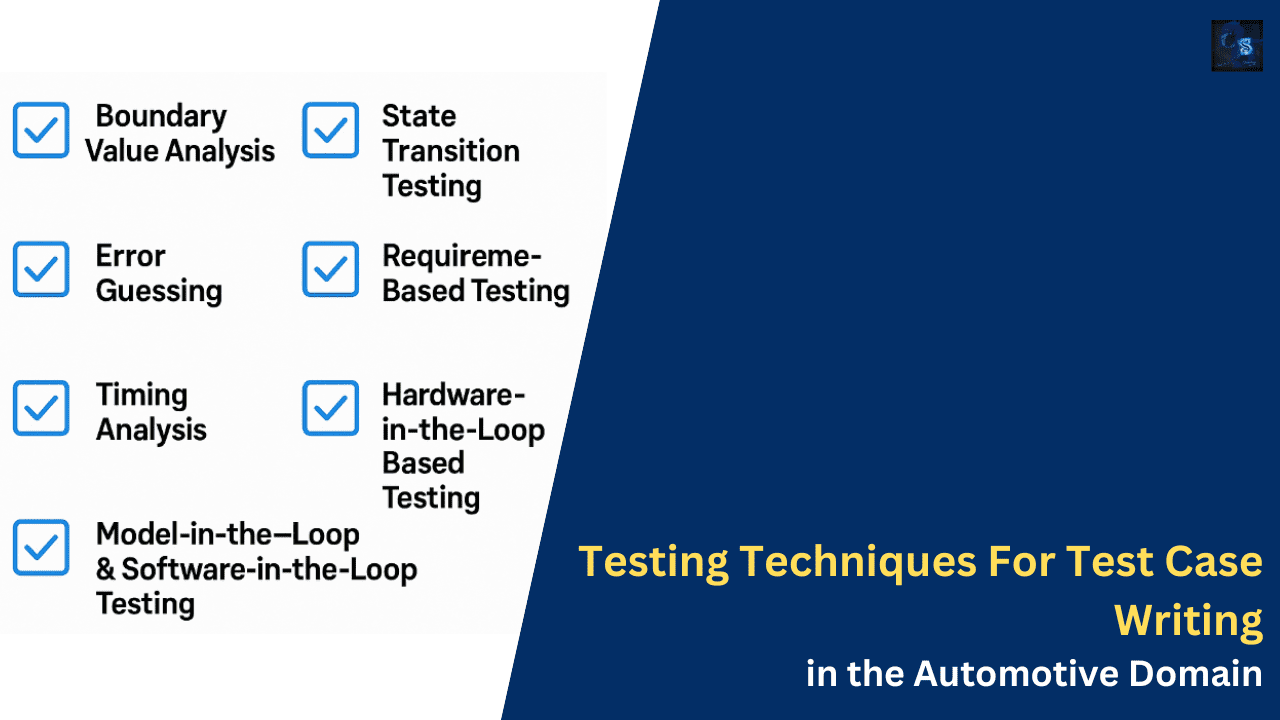

Testing Techniques For Test Case Writing in the Automotive Domain

Hello guys, welcome back to our blog. In this article, I will discuss the testing techniques for test case writing in the Automotive domain.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Different Storage Classes In MATLAB Simulink

- Mini Project / Hands-on Demo for Software-Defined Vehicles (SDVs): Part 08

- Challenges And Opportunities In Software Defined Vehicles (SDVs): Part 07

Testing Techniques For Test Case Writing in the Automotive Domain

The automotive industry is experiencing a major technological transformation, driven by advancements in embedded systems, electronics, software, and connectivity. As vehicles become increasingly software-defined, the importance of rigorous testing cannot be overstated. Ensuring the correctness, safety, and compliance of automotive systems requires a structured approach to test case design and implementation.

In this article, we will explore the most effective testing techniques used in writing test cases for automotive systems. Each technique is presented with a clear explanation, examples, and relevance to the automotive context. The total content is aimed to exceed 3000 words to serve as a comprehensive guide for engineers, testers, and quality assurance professionals.

01. Equivalence Partitioning

Equivalence Partitioning is a black-box test design technique that divides input data into partitions of equivalent data from which test cases can be derived.

Explanation: Instead of testing every possible input, testers select one input from each partition. If one test in a partition passes, the others are assumed to work too. This reduces the number of test cases while maintaining effective coverage.

Automotive Example:

- Consider a speed governor that accepts inputs from 0 to 250 km/h.

- Valid partitions: 0-250

- Invalid partitions: below 0, above 250

Write test cases such as:

- Input = 120 (valid)

- Input = -10 (invalid)

- Input = 300 (invalid)

Why It Matters: Reduces redundancy in test cases while ensuring coverage of valid and invalid input ranges.

02. Boundary Value Analysis (BVA)

Boundary Value Analysis focuses on testing the boundaries between partitions.

Explanation: Bugs often occur at the boundaries rather than the center of input ranges. Hence, BVA ensures these critical edge values are tested thoroughly.

Automotive Example:

- For a fuel sensor range of 0–100%:

- Boundary values: 0, 1, 99, 100

- Invalid values: -1, 101

Test cases should include these exact boundary values to catch edge case errors.

Why It Matters: Boundary conditions in ECUs, sensor interfaces, and safety-critical systems are highly susceptible to failure.

03. State Transition Testing

State Transition Testing is used when the system behavior depends on state changes.

Explanation: This technique ensures that all valid and invalid transitions between states are tested.

Automotive Example: Consider an Engine Start-Stop system:

- States: OFF, IGNITION, CRANK, RUN

- Transitions: OFF -> IGNITION -> CRANK -> RUN

Test cases should cover:

- Valid transitions

- Invalid transitions (e.g., CRANK -> OFF directly)

- Events causing the transition (e.g., key turn, engine fault)

Why It Matters: ECUs are essentially state machines, and their reliability depends on correct transitions.

04. Decision Table Testing

Decision Table Testing represents different combinations of inputs and the corresponding system outputs in a tabular form.

Explanation: This technique is especially useful when business logic or rules are involved.

Automotive Example: Headlight control logic:

- Conditions: Ignition ON/OFF, Light Sensor ON/OFF, Ambient Light LOW/HIGH

- Actions: Headlight ON/OFF

- Create a decision table that lists all combinations and expected outcomes.

Why It Matters: Ensures coverage of complex logic scenarios found in body control modules, lighting systems, and infotainment.

05. Use Case Testing

Use Case Testing is derived from real-world user scenarios.

Explanation: It validates the functional correctness from an end-user perspective.

Automotive Example: Adaptive Cruise Control Use Case:

- Set speed, detect vehicle ahead, auto-adjust speed, return to set speed

- Design test cases to simulate each step and user interaction.

Why It Matters: Confirms the system meets user expectations and real-world functionality.

06. Error Guessing

Error Guessing is a heuristic technique based on the tester’s experience.

Explanation: Testers use intuition and past experience to identify areas where bugs are likely to occur.

Automotive Example:

- Disconnecting sensors

- Injecting noise in CAN messages

- Rapid key cycles

Why It Matters: Catches hard-to-find bugs, especially in stress, corner cases, or fault conditions.

07. Requirements-Based Testing

This approach derives test cases directly from requirements.

Explanation: Each functional or safety requirement should have corresponding test cases.

Automotive Example:

- Requirement: If speed > 20 km/h and doors are unlocked, the system must lock doors.

- Test input: Speed = 25 km/h, Doors = unlocked

- Expected output: Doors lock

Why It Matters: Ensures traceability and verification of every requirement, essential for safety standards like ISO 26262.

08. Fault Injection Testing

Fault Injection involves introducing errors into the system to test its robustness.

Explanation: Simulates real-world faults and verifies system response.

Automotive Example:

- CAN bus failure

- Sensor shorted to ground

- ECU disconnection

Why It Matters: Essential for validating system behavior under fault conditions. Required in safety-critical systems.

09. Path Testing

Path Testing is a white-box technique used to test all logical paths in code.

Explanation: Ensures that all possible execution paths are tested at least once.

Automotive Example: A braking system algorithm with logic for:

- Normal braking

- ABS activation

- Hill hold

Write tests to ensure each path is exercised.

Why It Matters: Helps in unit testing and white-box verification of safety modules.

10. Timing Analysis

This technique tests timing constraints and deadlines.

Explanation: Ensures the system performs operations within the specified time window.

Automotive Example:

- Airbag deployment must occur within 20 ms of impact detection

- ECU boot-up time should be <1 second

Why It Matters: Failure to meet real-time deadlines can lead to catastrophic consequences in automotive systems.

11. Hardware-in-the-Loop (HiL) Testing

HiL testing involves connecting the ECU to a real-time simulation environment.

Explanation: Simulates vehicle behavior to test embedded software in real-world conditions.

Automotive Example:

- Simulate wheel speeds, yaw rate, and steering input to test the ESC ECU

Why It Matters: Provides early validation without needing a complete vehicle.

12. Model-in-the-Loop (MiL) and Software-in-the-Loop (SiL) Testing

MiL tests the control logic at the model level. SiL tests the generated code in a simulated environment.

Explanation: Validates algorithms and auto-generated code before hardware integration.

Automotive Example:

- Simulate throttle control logic

- Test the generated code for the powertrain controller in SiL

Why It Matters: Reduces bugs at early stages and enables early debugging.

Tools Commonly Used in Automotive Testing:

- CANoe, CANalyzer (Vector Informatik) – for network simulation and analysis

- dSPACE, NI HiL Systems – for Hardware-in-the-Loop setups

- Simulink, MATLAB – for model-based design and testing

- QTest, IBM Rational, TestLink – for test management

Conclusion

Automotive systems demand a high degree of reliability, accuracy, and safety. A well-structured test case design using a combination of these techniques ensures comprehensive coverage and defect detection at various levels — from unit to system integration.

Whether you’re validating a basic body control function or a complex ADAS feature, understanding and applying these testing techniques will make your testing efforts more effective, compliant, and robust. As the automotive landscape evolves with autonomous driving and electrification, testing strategies must become even more meticulous and intelligent.

By mastering these techniques, testers can significantly contribute to building safer, smarter, and more reliable vehicles.

This was about “Testing Techniques For Test Case Writing in the Automotive Domain“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?