The Future Of Battery Management Systems In The Era Of Software Defined Vehicles

Hello, everyone. Welcome back to my blog. In this article, I will discuss the future of battery management systems in the era of software-defined vehicles, including the challenges they present.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics

- Automotive-Grade Microcontrollers Vs General-Purpose MCUs: What Sets Them Apart?

- Upcoming Technologies To Learn In The Automotive Industry To Get High-Paying Jobs

- How Is DoIP Different From CAN-based Diagnostics?

Future Of Battery Management Systems In The Era Of Software-Defined Vehicles

The automotive industry is undergoing a radical transformation. The transition from hardware-centric vehicles to software-defined vehicles (SDVs) is reshaping every component in the car, including one of the most critical systems—the Battery Management System (BMS).

With the global push toward electrification and autonomy, the BMS has evolved from a basic safety component into a software-driven intelligence hub. It now plays a pivotal role in optimizing performance, extending battery life, enabling fast charging, and integrating with the vehicle’s digital nervous system.

This article explores how the BMS is adapting to the rise of SDVs, the core challenges faced, technological advancements underway, and what the future holds for this vital system.

What Is a Battery Management System?

A Battery Management System (BMS) is an embedded system responsible for monitoring, controlling, and safeguarding rechargeable battery packs. It ensures optimal operation by:

- Monitoring state of charge (SOC)

- Estimating state of health (SOH)

- Balancing cells

- Preventing overcharging or deep discharging

- Enabling thermal management

- Ensuring safe communication with the vehicle

Historically, BMSs were standalone hardware modules with firmware tuned for specific chemistries and pack designs. Today, their functionality is deeply intertwined with vehicle control, user interfaces, cloud connectivity, and AI-based predictions.

What Are Software-Defined Vehicles (SDVs)?

An SDV is a vehicle where software dictates most of the functionality, not just the user experience but also safety-critical systems like braking, steering, and energy management.

Key traits of SDVs include:

- Centralized computing platforms

- Service-oriented architecture (SOA)

- Over-the-Air (OTA) updates

- Containerized software (e.g., Docker in vehicles)

- Cloud-integrated diagnostics and analytics

- Support for Vehicle-to-Everything (V2X) communication

In this new paradigm, even the BMS is expected to operate within a modular, software-driven ecosystem—exposing APIs, supporting remote updates, and adapting dynamically to usage and battery conditions.

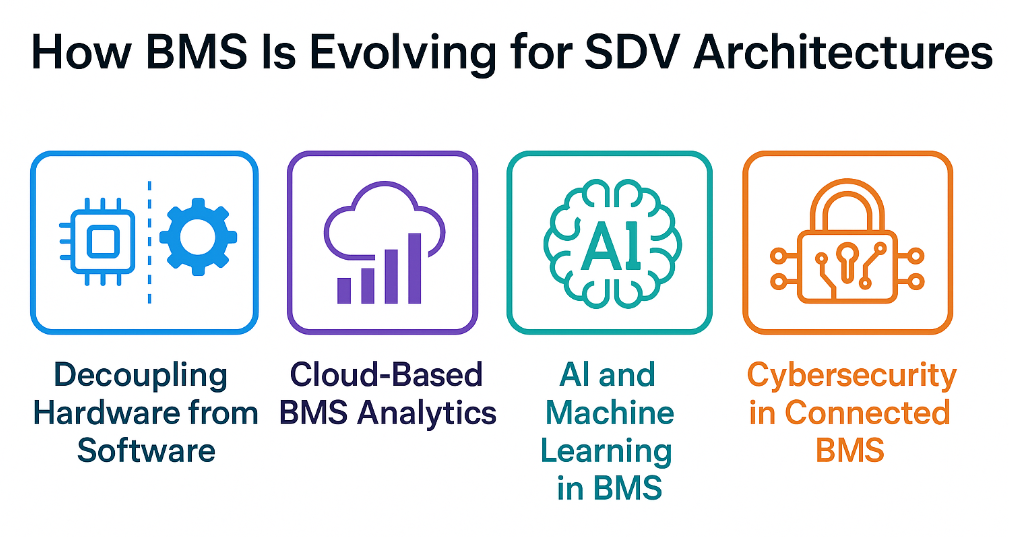

How BMS Is Evolving for SDV Architectures

01. Decoupling Hardware from Software: Modern SDVs promote abstraction between hardware and software. BMS firmware is evolving into modular software blocks, enabling:

- Cross-platform portability (e.g., using AUTOSAR or Adaptive AUTOSAR)

- Simulation-based development (HiL, SiL, MiL)

- Faster validation via virtual ECUs

This transformation empowers OEMs to push OTA updates to BMS logic for bug fixes, parameter tuning, or performance enhancements—something previously impossible without physical intervention.

02. Cloud-Based BMS Analytics: The cloud is increasingly being leveraged to store, analyze, and visualize battery data across fleets. Key benefits include:

- Predictive maintenance based on real-world usage patterns

- Battery usage profiling to guide charging behaviors

- Fleet-level degradation trends

While the core safety-critical logic remains on the edge (inside the vehicle), non-critical computations can be shifted to the cloud for scale and flexibility.

03. AI and Machine Learning in BMS: BMSs are becoming more intelligent with AI-based estimation techniques, such as:

- Neural networks for SOC/SOH estimation

- Reinforcement learning for charging control

- Anomaly detection for thermal runaway prediction

SDVs provide the computing power and integration pathways to enable such advanced models, which would have been computationally infeasible in legacy architectures.

04. Cybersecurity in Connected BMS: With remote connectivity comes the risk of intrusion. The modern BMS must follow automotive cybersecurity standards like:

- ISO/SAE 21434

- UN R155 compliance

From encrypted CAN messages to secure boot and runtime integrity checks, BMS software must now embed multi-layered defense mechanisms.

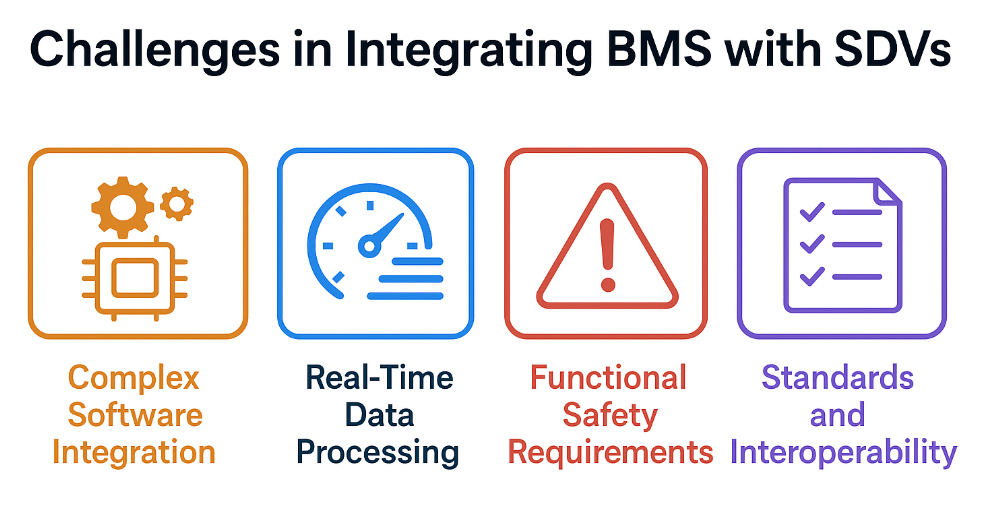

Challenges in Integrating BMS with SDVs

While promising, the transition introduces new challenges:

a. Real-Time Constraints: Battery safety decisions must be made within milliseconds. Integrating with centralized computing platforms (common in SDVs) introduces latency and scheduling complexity.

b. Certification & Compliance: Safety-critical software must comply with:

- ISO 26262 (ASIL levels)

- Functional safety assessments

- Model-based development with traceability

As software complexity increases, so do validation requirements.

c. Managing OTA Risk: Updating BMS logic over the air comes with the risk of bricking or safety failure. Therefore, fail-safe architectures, rollback mechanisms, and redundancy must be in place.

d. Interfacing with Cloud and V2X Systems: Interfacing the BMS with cloud services (via 5G) or with V2X for grid interaction (V2G) requires strong interoperability and standardization.

BMS and Its Role in Vehicle-to-Grid (V2G) Ecosystems

In the SDV world, the BMS is expected to interact with the grid for:

- Energy arbitrage

- Demand response programs

- Bi-directional charging (V2H, V2G, V2L)

This requires the BMS to evaluate:

- Battery condition before discharging to the grid

- Grid load conditions

- Owner’s usage preferences

Protocols like ISO 15118 and OCPP are gaining traction for BMS-grid communication.

Future Technologies in BMS for SDVs

🌡️ Solid-State Battery Support: New chemistries (like solid-state) require redesigned BMS algorithms to:

- Detect degradation without liquid electrolytes

- Manage temperature more precisely

- Interface with next-gen chargers (up to 800V systems)

📈 Edge AI BMS Controllers: Upcoming microcontrollers (e.g., S32, Aurix, RISC-V based) support onboard AI, enabling real-time pattern recognition and decision-making within the BMS itself.

🧠 Software Containers for BMS Functions: Some SDV platforms now run BMS modules in containers (like Docker or QNX microservices), enabling:

- Isolated updates

- Multi-tenancy of software components

- CI/CD pipeline integration for BMS algorithms

Case Study: Centralized BMS in an SDV Architecture

A global EV OEM recently transitioned from distributed ECUs to a centralized SDV platform, where the BMS logic runs on a zonal controller.

Benefits observed:

- 30% improvement in energy optimization due to cross-domain data

- OTA BMS tuning improved range estimation accuracy by 15%

- Cloud analytics reduced battery failures by early detection

The Role of Standardization

Key standards driving future BMS-SDV integration include:

- AUTOSAR Adaptive Platform

- ISO 26262

- ISO 15118 (for charging)

- UN R156 (OTA)

- UNECE WP.29 (Cybersecurity)

Compliance with these is critical for OEMs and Tier-1 suppliers.

Collaboration with Stakeholders

In the SDV world, BMS developers must interface with:

- Product teams (for user features like range estimation)

- System architects (for EE architecture planning)

- Cloud teams (for data pipeline integration)

- Regulatory bodies (for safety validation)

This ecosystem-wide collaboration ensures seamless functionality across the vehicle lifecycle.

Conclusion: The Software-Defined Future of BMS

The Battery Management System is no longer a hidden hardware component—it’s a core enabler of energy efficiency, vehicle safety, and customer experience in the SDV era.

To stay competitive, BMS engineers must embrace software-defined paradigms, modular development, real-time data analytics, and secure connectivity. With every innovation in computing, connectivity, and chemistry, the BMS evolves into a smarter, more strategic asset—powering not just the vehicle, but the mobility future itself.

This was about “Future Of Battery Management Systems In The Era Of Software-Defined Vehicles“. Thank you for reading.

Also, read:

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 1000+ Automotive Interview Questions With Answers

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024

- 50 Advanced Level Interview Questions On CAPL Scripting

- 7 Ways EV Batteries Stay Safe From Thermal Runaway

- 8 Reasons Why EVs Can’t Fully Replace ICE Vehicles in India

- A Complete Guide To FlexRay Automotive Protocol

- Adaptive AUTOSAR Vs Classic AUTOSAR: Which One For Future Vehicles?