Top Types Of Testing On Power Transformers Done Before Use

Hello guys, welcome back to my blog. In this article, I will discuss the top types of testing on power transformers done before use, power transformer testing tools, or types of tools used for power transformer testing.

If you have any doubts related to electrical, electronics, and computer science, then ask questions. You can also catch me @ Instagram – Chetan Shidling.

Also, read:

- Top 10 Amazing Autonomous Vehicles Makers That Will Attract You

- Overhead Line Components, Functions Of Components In Overhead Lines

- Top Best MTech Branches For Electrical & Electronics Engineers

Types Of Testing On Power Transformers

All transformers, old or latest, passed to a substation for the connection must be examined or inspected and tested before energizing. The final agreement for service of all transformers is the ability of the Regional System Maintenance Supervisor.

01. Oxygen Test

As nitrogen (which cannot support life) is usually used in the gas space over the oil in transformers, oxygen-testing equipment must be utilized to check the oxygen content preceding entry into the tank. Furthermore, monitor the oxygen content while working inside the transformer. Caution: if the Oxygen Content is Less Than 19.5%, Never Enter a Transformer.

02. Combustible Gas Test

Before getting into a transformer, test for combustible gas. The greatest acceptable level of combustible gas for secured entry is 10% of the lower explosive limit (LEL).

03. Carbon Monoxide Test

A carbon monoxide test should be conducted before entering a transformer. Carbon monoxide (CO) should last less than 25 parts per million (ppm).

04. Ground to Guard Against Static Charges

Static charges can occur in the windings while electrical tests and in the transformer oil as it flows by pipes, hoses, and tanks. Through oil flow into any tank, ground the tanker, transformer tank, filter press, piping, and all bushings or winding leads.

These grounds should be kept for at least an hour after the oil flow has stopped. To avoid/stop charges in the transformer windings, ground the windings before and later conduct winding electrical tests. If the transformer tank is not forever grounded, ground it temporarily during the test.

06. Core Ground Test

The core ground test (conducted on core form units only) determines the behavior of haphazard ground on the transformer core via checking the core ground insulation resistance utilizing a 1000 V megger with the industry core ground detached. Test values improved to 20°C should be 25 MΩ or higher. Report results on Power Transformer Acceptance and Maintenance Checklist.

07. Transformer Turns Ratio (TTR) Test

The TTR test measures or reads the turns ratio of the windings and identifies open-circuited and short-circuited turns.

- For proper connections to transformers, lead to the TTR test set instruction book.

- Conduct a test on all tap positions.

- Set transformer on tap to be utilized and retested. Results on each tap should be in 0.5% of the theoretical turns ratio.

- If adequate TTR test results cannot be achieved on all phases, not only the phase or phases that are inadequate, note either of the following: High exciting current and low voltage on the TTR test set (indicative of a short circuit on one of the windings) Normal exciting current and normal voltage but no galvanometer deflection on TTR test set (indicative of an open circuit).

- Record test results on the TTR Test Results form.

08. Doble Test

The Doble test is conducted on transformer windings and bushings by a junior engineer / Insulation Technician. The test is a relevant measure of the status of the insulation. The Insulation Technician will make suggestions.

09. Megger Test

The Megger test is an inspection of the insulation resistance. Separate solid connections of windings to the ground. The subsequent tests are made using 1000V megger:

- Measure from the high-voltage winding to the low-voltage winding and ground. (Low-voltage winding is grounded.) H-LG

- Measure from the low-voltage winding to the high-voltage winding and ground. (High-voltage winding is grounded.) L-HG

- Measure from the high- and low-voltage windings to the ground. HL-G

- Megger readings are temperature-dependent.

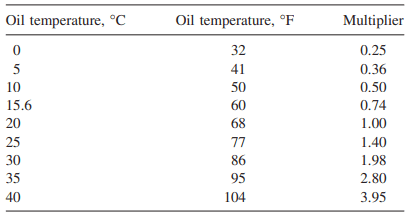

- Correct all the up readings to 20°C by multiplying the megger readings by the multipliers given in Table.

- The readings for the H-LG, L-HG, and HL-G tests should be relative to prior megger readings, with all readings corrected to 20°C (68°F).

- If past readings are not ready, the minimum acceptable resistance for each reading is per table.

- Record megger readings on Megger Test Results form.

10. Oil Tests

To stop air from being carried into transformers with a sealed tank or gas-oil-seal designs, get sure the gas space over the oil is at a positive pressure before removing the drain valve. For all transformers, conduct oil dielectric and acidity tests. Refer to instruction:

- Insulating Oil: Using, Handling, Sampling, and Testing.

- Record results on Power Transformer Acceptance and Maintenance Checklist.

- For new and rebuilt transformers, send oil samples for further tests to the Chemical Laboratory.

- A copy of the test results should be given to Substation Component Engineering.

11. Oxygen Content Test

High oxygen content occurs in the oxidation of oil, which creates sludging. The gas space in each sealed transformer is to be tested semiannually for oxygen content. Document results on Power Transformer Acceptance and Maintenance Checklist. Oxygen content should not surpass 5%. When needed, the gas space should be cleaned with dry nitrogen until the oxygen content is 1% or less.

12. Excitation Test

This test is done with Doble devices by the Insulation Technician, who will make suggestions.

13. Gas-in-Oil Analysis

Every six months or twice a year, samples of oil are to be used for gas-in-oil analyses from all 69 kV and above power transformers and generating station transformers.

This was about ” Types Of Testing On Power Transformers “. I hope this article ” Types Of Testing On Power Transformers ” may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Automotive Interview Questions With Answers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students