What Is Battery Management System, Working, Advantages Of BMS

Hello guys, welcome back to my blog. In this article, I will discuss what is battery management system, working of battery management system, advantages of BMS, functions of BMS, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask questions. You can also catch me on Instagram – Chetan Shidling.

Also, read:

- Top And Bottom Cell Balancing Using A Flyback Converter Balancing

- What Is IEEE, How To Publish Research Paper At IEEE, IEEE Membership

- Top Tools For Control System Design, Software For Control System

What Is Battery Management System

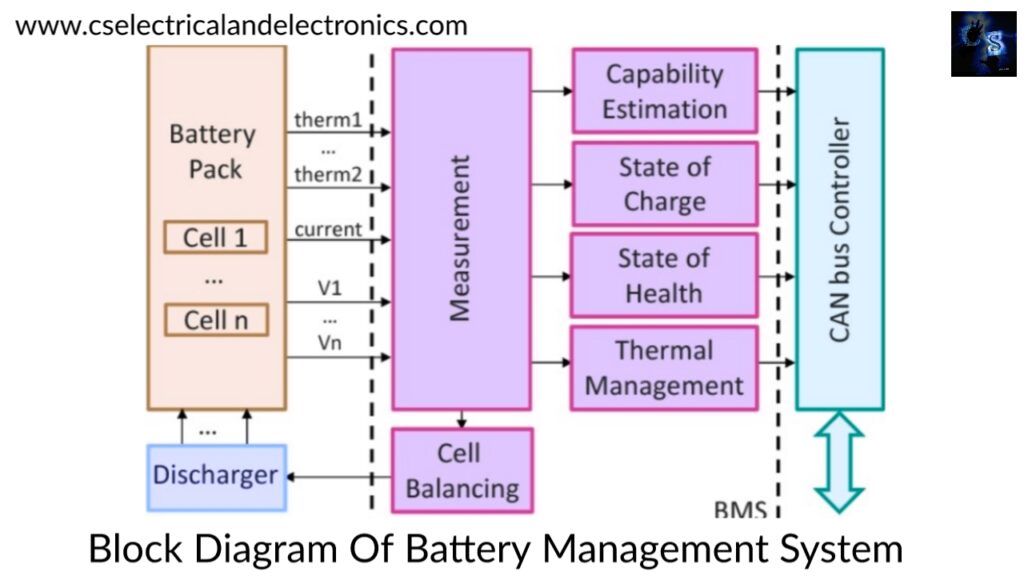

During the charging and discharging of the battery, a Battery Management System, or BMS, monitors and adjusts internal operating parameters such as temperature, voltage, and current. To enhance battery safety and performance, the BMS calculates the battery’s SoC (State of Charge) and SoH (State of Health).

It prevents the battery pack from being overcharged or discharged. This prevents unexpected mishaps [explosions] by keeping the charge level within the maximum and minimum permitted capacities. As a result, a BMS is extremely important equipment for ensuring the battery’s and user’s safety.

A BMS is a circuit board made up of various components and circuits. When a problem with operational parameters (voltage, temperature, etc.) is detected, the BMS sends an alarm signal to the alarm system, which then disconnects the battery pack from the load or charger.

Building Blocks of Battery Management System:

A battery management system includes cutoff FETs, a fuel gauge monitor, cell voltage monitor, cell voltage balance, real-time clock (RTC), temperature monitors, and a state machine, to name a few functional blocks. Battery management integrated circuits are available in a range of forms and sizes. The functional components are organized in several ways, ranging from a simple analog front-end with balancing and monitoring that requires a microcontroller (MCU) to a self-contained, fully integrated system. Let’s look at each block’s function and technology, as well as its pros and downsides.

01. Cutoff FETs and FET Driver

A FET driver functional block is responsible for connecting and isolating the battery pack from the load and charger. The behavior of the FET driver is determined by battery cell voltage readings, current measurements, and real-time detecting circuitry.

02. Fuel Gauge / Current Measurements

The charge entering and departing the battery pack is tracked by the fuel gauge functional block. The product of current and time in charge. When it comes to constructing a gasoline gauge, there are a variety of options. One technique of detecting current is to use a current sensing amplifier and an MCU with an integrated low-resolution ADC.

The current sense amplifier enhances the signal in high common-mode conditions, allowing for greater resolution measurements. The dynamic range is sacrificed in this design method. Other options include using a high-resolution ADC or purchasing a pricey fuel gauge IC. The optimum sort of gasoline gauge design is determined by understanding the behavior of the load in terms of current consumption vs time.

03. Cell Voltage and Maximizing Battery Lifetime

To determine the overall health of a battery pack, it is necessary to monitor the cell voltage of each cell. To guarantee optimal functioning and battery life, all cells have an operating voltage window within which charging, and discharging should take place. When a lithium-ion battery is used in an application, the operating voltage is generally between 2.5V and 4.2V.

The voltage range is determined by the chemical. Operating the battery outside of the voltage range drastically decreases the cell’s lifespan and may render it unusable. A battery pack is made up of cells linked in series and parallel.

04. Improving the ON Time of a Battery Pack Per Charge

There are two methods for increasing the ON time per charge of a battery pack. The first is to connect a bypass FET to a current limiting resistor across the weakest cell to minimize the amount of charge received during the charging cycle.

This technique diverts current away from the cell with the highest current, slowing its charge and allowing the other cells in the battery pack to catch up. The goal is to maximize the battery pack’s charge capacity by ensuring that all of the cells reach full charge at the same time.

05. Temperature Monitoring

For energy storage system (ESS) applications or a cluster of cells for smaller and more portable applications, temperature sensors monitor each cell. Thermistors with an inbuilt ADC voltage reference are widely used to monitor the temperature of each circuit. The internal voltage reference is utilized to decrease temperature reading errors due to temperature fluctuations in the surroundings.

Working of Battery Management System:

The intricacy of the electronic components on board determines how well a battery management system works. Let’s take a closer look at how it works by examining a typical BMS with the bare minimum of components for optimal performance. The BMS’s microprocessor monitors the cell voltage and current in real-time and changes the MOSFETs accordingly.

For charging and discharging, the BMS employs only one bus. There is no current flow at first since both charging and discharging FETs are turned off. The BMS’s microprocessor detects the voltage at the input and activates the charging MOSFET, which re-charges the battery. If no voltage is available at the input pin, the BMS assumes the load is connected and activates the discharging FET.

In most BMSs, there are two forms of cell balancing:

- Passive cell balancing

- Active cell balancing

Bypass resistors are used in passive cell balancing to discharge excess voltage and equalize with other cells. The excess charge of one cell is transferred to another cell with a low charge in the active cell balancing to balance the charges. Charge-storage capacitors and inductors are used.

Advantages of Battery Management System:

- Ensure that the battery is in good working order.

- Battery health is continuously monitored to avoid an explosion.

- Extends the battery’s life expectancy.

- Displays the battery level.

To summarize, battery management systems may be built utilizing several different functional blocks and design methods. The proper architecture, functional blocks, and associated ICs to construct your battery management system and charging scheme to improve battery life will be determined by careful evaluation of battery needs and battery life goals.

This was about “What is battery management system”. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Automotive Interview Questions With Answers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students