What Is BLDC Motor, Construction, Working, Types, Applications

Hello guys, welcome back to my blog. In this article, I will discuss what is BLDC motor, the construction of the motor, its working, advantages, disadvantages, types, and applications of BLDC motor.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- What Is MPPT, Maximum Power Point Tracker, Types Of MPPT Algorithm

- Top Reason Why Electric Bikes Are Catching Fire? Be Safe

- What Are Hysteresis Losses, Causes, How To Optimize Hysteresis Losses

What Is BLDC Motor, Construction, Working, Types, Applications, Advantages, Disadvantages

BLDC stands for “ Brushless Dc motor”. That means these motors do not have brushes in them.

Brushless DC electric motors can also be called electronically commutated motors, which are powered by DC electric source through an integrated inverter or switching power supply, which produces an AC electric signal to drive the motor.

Construction Of BLDC Motor

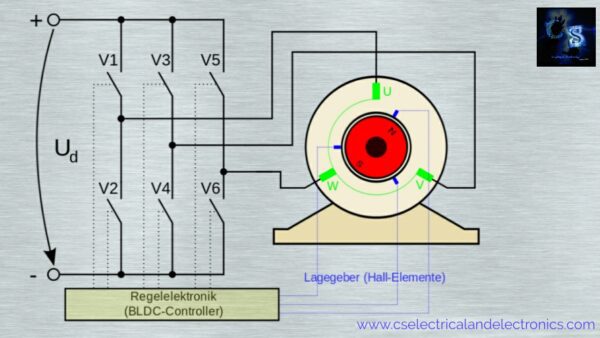

The stator has 3 phase winding, while the rotor is in the form of a permanent magnet.

The rotating of the rotor will completely depend on the current produced by the stator, and the speed can be controlled by controlling the stator current.

BLDC motor consists of rotor position sensors that produce electric signals. These electric signals indicate the current position of the rotor.

The stator winding of the BLDC motor can be driven from an electronic drive, which will be 3 phase inverter.

The speed of the BLDC motor can be controlled by controlling the voltage of the stator, which can be achieved by controlling the inverter DC input voltage.

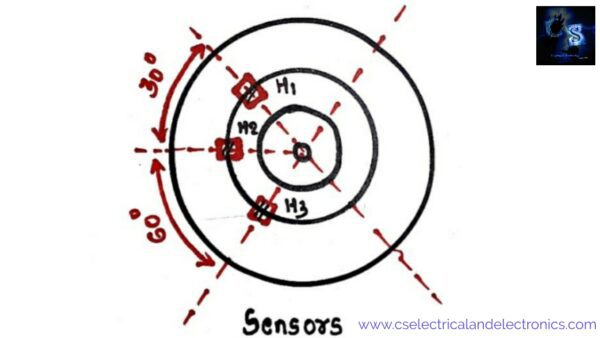

Hall Sensors

The permanent magnet brushless DC motors use hall sensors with 60° electrical spacing. These sensors produce a logic 1 when exposed to the N-type of the rotor and it produces logic 0 when exposed to the S-type of the rotor.

Working Of BLDC Motor

First, let’s see the function of a brushed motor. In brushed motors, there will be permanent magnets on the outside and a spinning armature. This spinning armature contains an electromagnet. This electromagnet creates a magnetic field in the armature when supply is given and helps to rotate the armature.

To keep the rotation of the armature, the brushes will change the polarity of the pole. The working principle of brushed DC motor and brushless DC motor is the same. i.e internal shaft position feedback.

The brushless DC motor has two windings. Rotor and stator. The rotor is a rotating part and has rotor magnets in it. Where stator is stationary winding that consists of a stator.

In the rotor, the permanent magnets are attached. To activate electromagnets, high-power transistors are used. The controller performs power distribution by making use of a solid-state circuit.

Types Of BLDC Motor

- 01. Outer rotor design.

- 02. Inner rotor design.

These two are different only in the designing part, but the working principle of both types will remain the same.

Designing Part Of Inner Rotor Design

In this type, the rotor is placed at the center of the motor and the rotor will be surrounded by the stator.

Rotor magnets do not insulate heat inside because the rotor is located in the core and heat gets dissipated easily. Due to this reason, the inner rotor-designed type of motor will produce, a large amount of torque.

Designing Part Of Outer Rotor Design

In this, the rotor surrounds the winding which is placed in the core of the motor. The magnets which are in the rotor, trap the heat of the motor inside and it doesn’t allow it to dissipate from the motor. This type of designed motor will operate at a lower-rated current and has low cogging torque.

Applications Of BLDC Motor

- It can be used in servo actuation.

- Positioning and variables speed.

- It can be used in aerospace.

- Used in air conditioners.

- Used in computer peripheral equipment.

- Used in biomedical instrumentation.

Advantages Of BLDC Motor

- Low maintenance cost.

- These are having a long life.

- Low friction and low inertia.

- High efficiency (>75%).

- Reliable operation.

Disadvantages Of BLDC Motor

- More expensive.

- Having a complex network.

- It needs complex electronic controllers.

I hope this article may help you all a lot. Thank you for reading.

Also read:

- Types Of Errors Found In MiL, SiL, And HiL Testing

- Top 100 StateFlow Interview Questions With Answers

- Designing An Automotive Test System For ECU Validation

- Top 30 Automotive-Specific ISO Standards Every Automotive Engineer Must Know

- Hazard Identification Techniques In Functional Safety (FuSa) ISO 26262

- Troubleshooting CAN Communication Failures In A Test Environment

- Code Generation In MATLAB Simulink, Things To Be Followed For Efficient Code Generation

- Variable-Step Solvers In MATLAB Simulink: Which One To Select