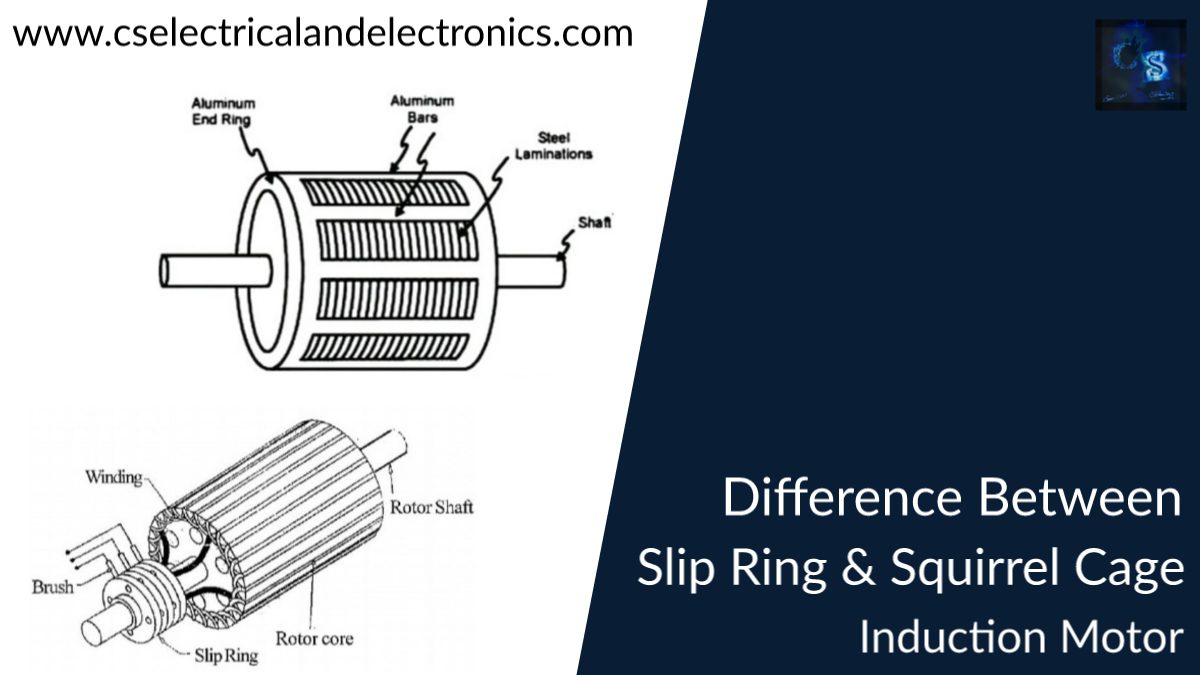

Difference Between Slip Ring And Squirrel Cage Induction Motor

Hello guys, welcome back to our blog. In this article, we will discuss the difference between slip ring and squirrel cage induction motor, what is an induction motor, and we will be sharing the advantages, disadvantages, & applications of both motors.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- What Is An Electric Wire Harness, Steps For Wire Harness, Purpose

- Top Electric Vehicle Interview Questions With Answers Must Know

- What Is Wireless BMS, Battery Management System, Benefits, Working

Difference Between Slip Ring And Squirrel Cage Induction Motor

The induction motor is classified as a squirrel cage and slip ring induction motor. The difference between squirrel cage and slip ring induction motor is mainly in torque, speed, slip, resistance, and reactance.

Applications of induction motor

Squirrel cage induction motor – Squirrel cage induction motors are usually used in various industrial applications. They are particularly suited for applications where the motor must maintain a constant speed, be self-starting, or there is a desire for low maintenance. These motors are commonly used in, Centrifugal pumps, Industrial drives (e.g. to run conveyor belts), Large blowers and fan machine tools lathes, and other turning equipment

Slip ring induction motor – Slip ring motors are most suitable for rolling mills, kilns. centrifugal fans, and blowers because all these high inertia equipment demands high starting torque.

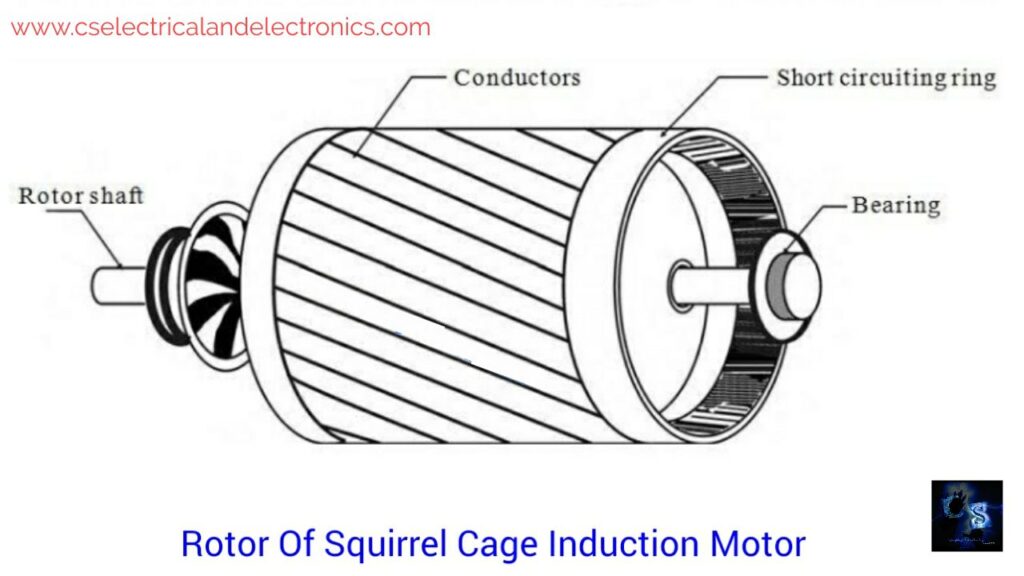

Squirrel cage induction motor

- In a Squirrel cage induction motor, the rotor is rugged and simplest in construction.

- A cylindrical laminated core rotor with heavy bars of copper or Aluminum is used for conductors.

- Rotor conductors or bars are short-circuited with end rings.

- Rotor bars are permanently short-circuited and hence it is impossible to connect an external resistance in the circuit in series with the rotor conductors.

- It has a low cost.

- There are no moving contacts in the rotor.

- Higher efficiency.

- Low starting torque. It has a 1.5-time full-load torque.

- Speed control is not possible by rotor resistance.

- The starting current is 5 to 7 times of full load current.

The advantages of skewing are as follows:

- There is a production of uniform torque. Due to this noise during operation reduces.

- The magnetic locking tendency of the rotor reduces. During the locking process, the stator and rotor teeth attract each other due to magnetic action. This locking process is called Cogging. To overcome magnetic locking due to cogging, that’s why conductors are skewed.

Note: The number of Poles and phases that develop automatically in a cage rotor is equal to the number of Poles and phases in a stator. This means that the rotor responds automatically to the change in stator poles.

Advantages of Squirrel cage Induction Motor

- Higher efficiency.

- Higher power factor.

- Robust construction.

- Less cost.

- The absence of brushes reduces the risk of sparking.

- Lesser maintenance.

- It has a good running performance.

Disadvantages of Squirrel cage Induction Motor

- Low starting torque.

- Rotor impedance at the time of starting is less. So starting current is high. Hence, it needs extra starting equipment.

- It has a poor starting performance.

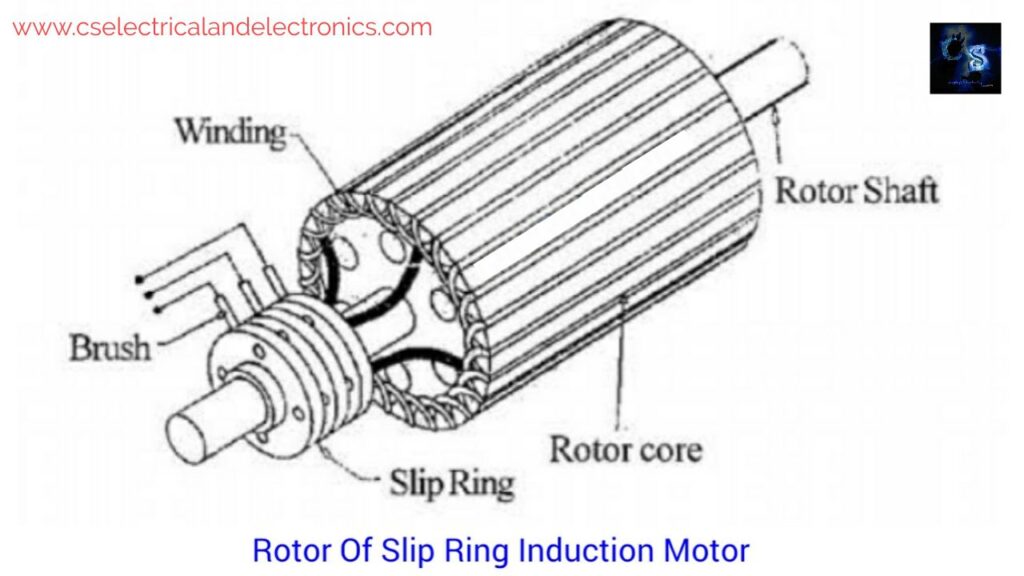

Slip-ring induction motor

- In slip-ring induction motors the rotor is wound type. In the slip ring induction motor the slip rings, and brushes are provided. Compared to the squirrel cage rotor, the rotor construction is not simple.

- The cylindrical laminated core rotor is wound-like winding on the stator

- At starting the 3-phase windings are connected to a star-connected rheostat and during the running condition, the windings are short-circuited at the slip rings.

- It is possible to insert additional resistance in the rotor circuit. Therefore it is possible to develop the torque; the extra series resistance is used for starting purposes.

- The cost is slightly higher.

- Carbon brushes, slip rings, etc. are provided in the rotor circuit.

- It has comparatively less efficiency.

- High starting torque. It can be achieved by adding external resistance in the rotor circuit.

- Speed control by rotor resistance is possible.

- Less starting current is there related to the squirrel cage Induction Motor.

Note

- The purpose of using phase resistance in the rotor circuit is to decrease the supply starting current and increase the starting torque.

- Secondly, it is used for controlling the speed of the motor.

- Rotor winding must be star connected.

- Like a stator, rotor windings must be distributed and short-pitched.

Advantages of Slip ring Motor

- High starting torque.

- Low starting current.

- External resistance can be connected to the rotor circuit to control the motor speed.

Disadvantages of Slip ring Motor

- The cost is high (3 times compare to a squirrel cage).

- Large Size.

- The space requirement increases.

- There are wear and tear.

- There is sparking.

- Maintenance is large.

Conclusion: hence, by the above information we can conclude which is the best suitable motor for our application purpose.

This was about “Difference Between Slip Ring And Squirrel Cage Induction Motor“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- Upcoming Technologies To Learn In The Automotive Industry To Get High-Paying Jobs

- How Is DoIP Different From CAN-based Diagnostics?

- Difference Between Domain And Zonal Architecture in Automotive: A Complete Guide

- Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer

- 1000+ Automotive Interview Questions With Answers

- RTOS In The Automotive Industry: The Brains Behind Real-Time Vehicle Control

- High Performance Computers in Software-Defined Vehicles (SDVs): Architecture, Challenges, and Future Trends

- Automotive HPC Wars: The Race To Power Software-Defined Vehicles