What Is PTO In Vehicle, Power Take-Off, Working

Hello guys, welcome back to our blog. Here in this article, we will discuss PTO (Power Take-Off) in vehicles, the working of power take-off, and its purpose.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- Vehicle Dynamics: Rolling Resistance, Aero Dynamics, Road Gradient

- Bajaj Freedom 125 CNG: Five Motives To Purchase It

- Different Types Of Torque Split Strategies For Hybrid Vehicles

PTO (Power Take-Off) In Vehicle

In the world of heavy-duty and commercial vehicles, Power Take-Off (PTO) technology is essential to expanding the vehicles’ capabilities beyond just transportation. Through the utilization of the engine power, PTO systems allow trucks to run various auxiliary equipment. With this flexibility, trucks become multipurpose devices that can handle a wide range of jobs, which makes them essential in sectors like utilities, emergency services, construction, and agriculture.

A mechanical device that distributes power from the truck’s engine to auxiliary equipment is the center of the PTO idea. The engine may now power extra equipment and tools like compressors, winches, and hydraulic pumps thanks to this power transfer. PTO systems minimize the need for additional power sources by using the truck’s current engine, which improves operational effectiveness and lowers expenses. This function integration is especially helpful in situations when multitasking and mobility are crucial.

The capacity of PTO systems in trucks to maximize the vehicle’s potential is one of its main benefits. For example, a tow truck with a PTO can utilize it to run winches and lifts, while a dump truck with one can use a hydraulic system to raise and lower its bed. PTOs are also used by utility trucks to run cranes and aerial lifts, and fire engines to power water pumps. This versatile versatility emphasizes how crucial PTO systems are to maximize the use of commercial vehicles.

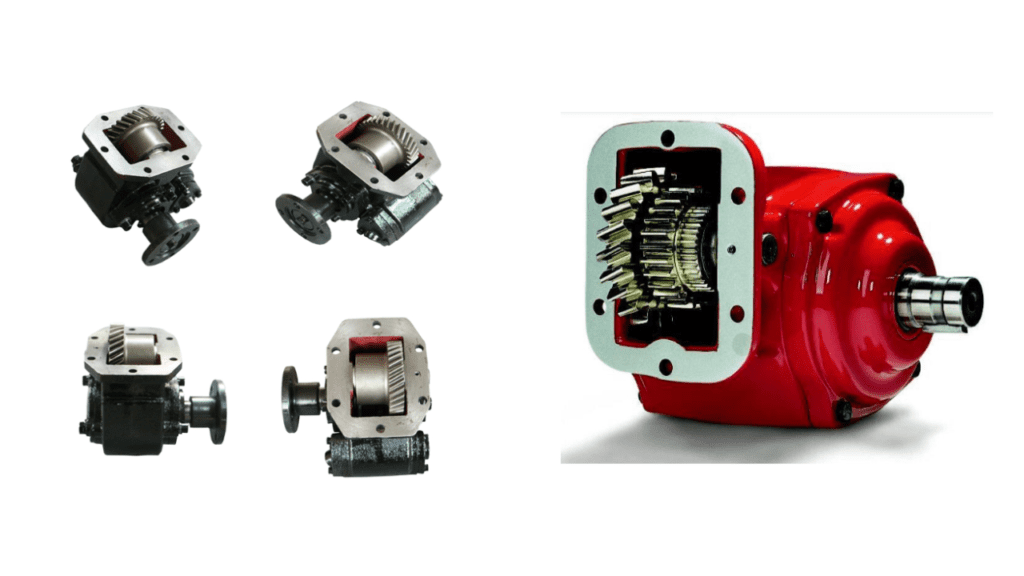

A driving shaft, auxiliary equipment, and the PTO unit itself are some of the essential parts that make up a PTO system. Usually attached to the truck’s engine or gearbox, the PTO unit can be turned on manually or electronically. After it is activated, the PTO moves engine power to the drive shaft, which then supplies power to the auxiliary equipment. The auxiliary equipment can carry out its intended duties thanks to this smooth power transfer, which improves the truck’s operational capabilities.

Finally, Power Take-Off systems are essential to the effectiveness and adaptability of contemporary trucks. PTO systems let a single vehicle do several tasks, which increases truck productivity while also saving money and improving operational efficiency. Trucks fitted with PTO systems are vital assets that greatly enhance the operating capabilities and financial sustainability of numerous businesses, be it construction, emergency services, or utility operations.

Working Of Power Take-Off

Through the transmission of engine power to auxiliary equipment, Power Take-Off (PTO) systems enable trucks to execute a wide range of jobs, hence improving their functionality. The PTO unit, the drive shaft, and the auxiliary equipment are the main parts of a PTO system. The main device that facilitates the transfer of power is the PTO unit, which is normally attached to the truck’s engine or gearbox. This power is transferred from the PTO unit to the auxiliary equipment through the drive shaft, allowing it to function.

When the PTO unit is engaged, a PTO system starts to function. This can be accomplished automatically by electronic controls or manually by a lever or switch located inside the truck cab. The PTO unit initiates the transfer of power by connecting to the truck’s engine or gearbox once it is engaged. In order to ensure effective power transmission, the PTO unit often has gears made to match the engine’s speed and torque with the unique needs of the auxiliary equipment.

Power is sent to the auxiliary equipment via the drive shaft after passing via the PTO unit. This equipment can raise, pump, and winch among other things thanks to the mechanical energy of the engine. For instance, the PTO drives the hydraulic system in dump trucks that raises and lowers the dump bed, and it powers the winches and lifts in tow vehicles. This adaptability emphasizes how crucial PTO systems are to optimize vehicles’ operational potential.

Diverse PTO system types meet different operational requirements. Heavy-duty trucks frequently use gearbox PTOs, which are directly connected to the truck’s gearbox. Engine PTOs are frequently seen in smaller cars or specific applications where high power output is required. They are placed directly on the engine. Split shaft PTOs are utilized in applications needing various auxiliary functions since they draw power from both the front and rear of the vehicle. For certain operational conditions, each kind is made to transfer power efficiently.

PTO systems can have many operating modes depending on the task at hand. When in stationary mode, which is appropriate for jobs like operating a concrete mixer, the truck stays motionless while the PTO drives the auxiliary equipment. When the truck is in mobile mode, it may move while the PTO is running, which is helpful for tasks like snowplowing and street sweeping. For PTO systems in trucks to operate safely and effectively, proper engagement, routine maintenance, and matching the power output to the needs of the auxiliary equipment are essential.

Function and Advantages of Truck Power Take-Off (PTO)

Trucks equipped with Power Take-Off (PTO) systems can use the engine’s power to power a variety of auxiliary tasks. With this ability, trucks become highly adaptable and multipurpose vehicles that are essential in a variety of industries. The following are the main goals and advantages of employing PTO systems in trucks:

01. Enhancing Flexibility: Trucks equipped with PTO systems can run a range of auxiliary machinery, including compressors, winches, and hydraulic pumps. Because of its adaptability, a single truck may handle a variety of jobs, negating the need for additional, specialized vehicles. For example, a fire truck can power water pumps, a tow vehicle can handle winches and lifts, and a dump truck can raise its load using a PTO. This versatility is especially useful in sectors like utilities, emergency services, construction, and agriculture.

02. Increasing Effectiveness: PTO systems increase operating efficiency by utilizing the truck’s current engine to operate auxiliary equipment. The PTO system uses the truck’s primary engine to operate the equipment rather than requiring different engines or power sources for each piece of machinery. Operations become more efficient and ecologically friendly as a result of this integration, which also lowers emissions and fuel consumption.

03. Reducing Expenses: Considerable cost savings are possible when PTO systems are used. PTO systems lower equipment and maintenance costs by doing away with the requirement for extra engines or power units. Fuel costs are further reduced by sharing the truck’s engine for both driving and auxiliary purposes. PTO-equipped vehicles are a financially viable choice for many organizations due to their cost-effectiveness.

04. Increasing Performance: PTO systems increase vehicles’ productivity by allowing them to complete difficult jobs quickly and effectively. To expedite the construction process, for instance, a PTO-driven concrete mixer may continuously mix and pour concrete on the job site. A PTO-powered crane can lift large weights during utility work, enabling a quicker and safer completion of the task. Businesses are better able to meet project deadlines and enhance overall operational performance because of this enhanced productivity.

05. Convenience and Safety: A handy and secure method of operating auxiliary equipment is offered by PTO systems. Accident risk is decreased because the operator may manage the equipment without getting out of the car thanks to the ability to engage and operate the PTO from the truck cab. Furthermore, by including PTO systems in the truck’s design, operational safety is increased because the auxiliary equipment can be powered regularly and dependably.

In conclusion, vehicles using PTO systems have greater adaptability, increased productivity, lower expenses, increased efficiency, safety, and convenience. Because of these advantages, PTO-equipped trucks are a need in many different industries, since they can easily and effectively complete a variety of difficult tasks.

This was about “PTO (Power Take-Off) In Vehicle“. Thank you for reading.

Also, read:

- The Future Of Battery Management Systems In The Era Of Software Defined Vehicles

- Automotive-Grade Microcontrollers Vs General-Purpose MCUs: What Sets Them Apart?

- Upcoming Technologies To Learn In The Automotive Industry To Get High-Paying Jobs

- How Is DoIP Different From CAN-based Diagnostics?

- Difference Between Domain And Zonal Architecture in Automotive: A Complete Guide

- Roadmap To Become A Successful Hardware-in-the-Loop (HiL) Engineer

- 1000+ Automotive Interview Questions With Answers

- RTOS In The Automotive Industry: The Brains Behind Real-Time Vehicle Control