What Is Squirrel Cage Induction Motor, Working Principle, Applications, Advantages, Disadvantages

Hello guys, welcome back to my blog. In this article, I will discuss what is squirrel cage induction motor, the working principle of the squirrel cage induction motor, applications, advantages of the squirrel cage induction motor, disadvantages of the squirrel cage induction motor, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- Speed Control Methods For Different Motors, AC Motor, DC Motor

- Top 10 Types Of Testing On Electrical Motors, Electrical Motor Testing

- Top Types Of Testing On Power Transformers Done Before Use

What Is Squirrel Cage Induction Motor

Introduction

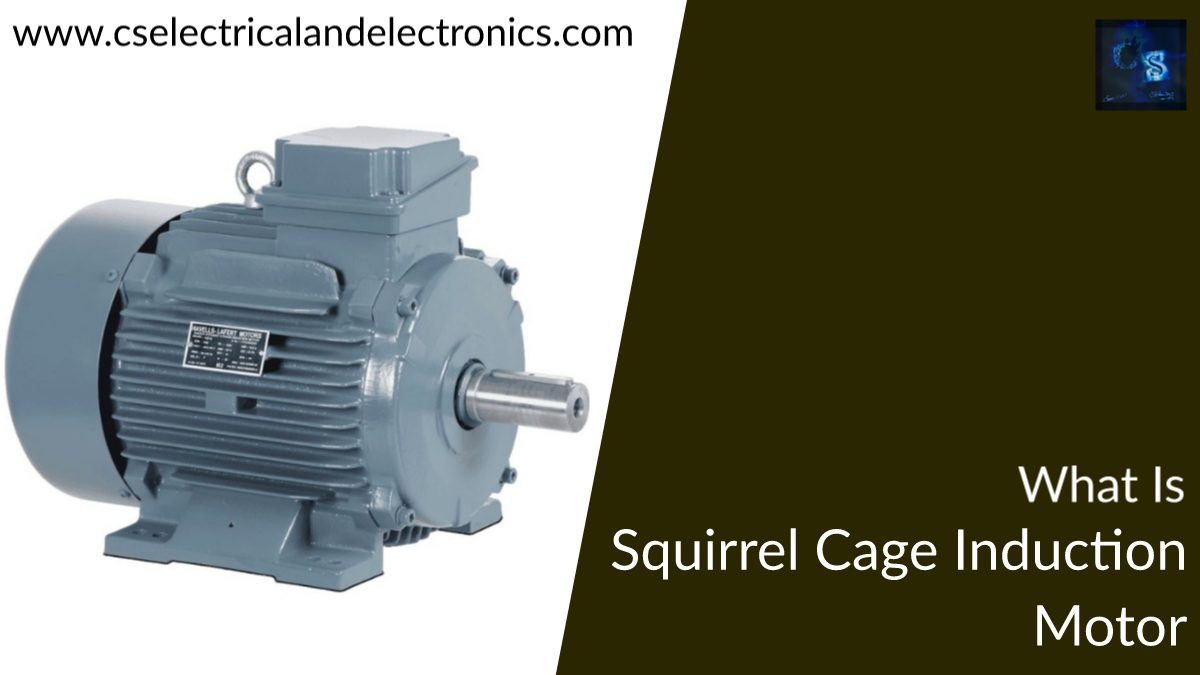

Squirrel cage induction motor is one of the types of 3 phase induction motor, which works under the principle of electromagnetism. It is called a squirrel cage motor because the rotor which is present in this motor looks like a squirrel cage. This motor will be cylindrical in shape which is laminated by steel and it is having highly conductive metals like aluminum and copper.

The big advantage of a squirrel cage induction motor is, we can change its speed-torque characteristics easily. It can be done by adjusting the shape of bars that are present in the rotor.

Construction

It mainly contains 4 parts;

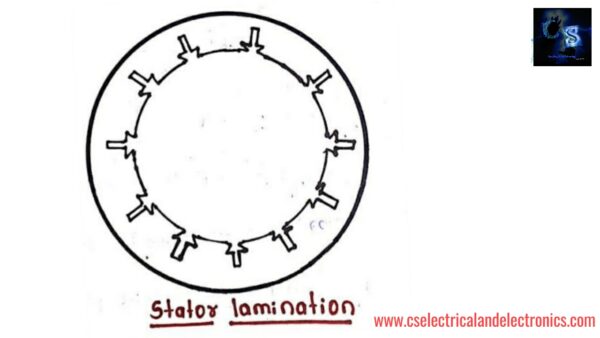

01. Stator

The stator contains 3 phase winding with a core. Stator windings will be placed in such a way that they should be 120° apart from each, both Electrically and mechanically. This winding will be mounted on a laminated iron core in order to provide a low reluctance path for flux and AC currents.

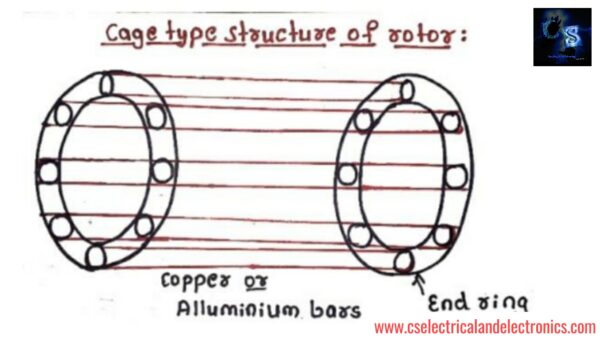

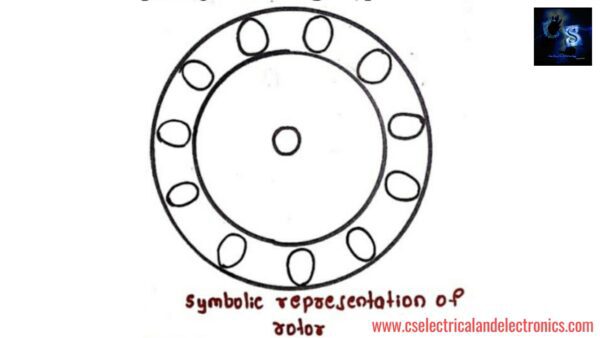

02. Rotor

The rotor is the rotating part of the motor which gives a mechanical output. The rotor contains a shaft, short-circuited aluminum or copper bars, and a core. The core will be laminated to avoid losses like eddy current and hysteresis losses. The rated output of the motor will be given on the nameplate in terms of horsepower.

03. Fan

The fan will be connected at the backside of the rotor Just to provide heat exchange. It maintains the temperature of the motor.

04. Bearings

These are provided as a base for the motion of the rotor. It helps the motor to keep a smooth rotation.

Working Principle Of Squirrel Cage Induction Motor

When we supply 3 phase AC power to the stator winding, it sets up a rotating magnetic field and this field will have a constant speed, which is called synchronous speed.

This rotating magnetic field produces the voltage in the rotor and due to this, current starts to flow in the rotor bars. These currents will generate their self-magnetic field. This field interacts with the stator field. The Rotor field will try to oppose the current and hence rotor starts to follow the rotating magnetic field.

The rotor current drops to zero when the rotor catches the rotating magnetic field, as there is no relative motion between the rotating magnetic field and the rotor. At this moment the rotor will experience zero tangential force. Therefore rotor decelerates for the moment. Then the relative motion between the rotor and rotating magnetic field will re-establishes, due to this the rotor current will be induced again. The tangential force of rotation of the rotor will be restored again. Then the rotor starts to follow the rotating magnetic field again. This rotor tries to maintain a constant speed.

Slip is the difference between the speed of the rotating magnetic field and rotor speed.

Frequency of the rotor current= slip× supply frequency

Applications Of Cage Induction Motor

- It is used in lathes and other turning equipment.

- Used in large blowers and fans.

- It is used in machine tools.

- Used in the industrial drive.

Advantages Of Cage Induction Motor

- Cheaper cost.

- Less maintenance.

- Good quality of speed regulation.

- High efficiency.

- Better heat regulation.

- Explosion-proof.

Disadvantages Of Cage Induction Motor

- Poor speed control.

- Having a high starting current and poor starting torque.

- Energy consumption is more.

- More sensitive to fluctuations.

I hope this article may help you all a lot. Thank you for reading.

Also read:

- 1000+ Automotive Interview Questions With Answers

- Types Of Errors Found In MiL, SiL, And HiL Testing

- Top 100 StateFlow Interview Questions With Answers

- Designing An Automotive Test System For ECU Validation

- Top 30 Automotive-Specific ISO Standards Every Automotive Engineer Must Know

- Hazard Identification Techniques In Functional Safety (FuSa) ISO 26262

- Troubleshooting CAN Communication Failures In A Test Environment

- Code Generation In MATLAB Simulink, Things To Be Followed For Efficient Code Generation