What Is Slip Ring Induction Motor, Working, Advantages, Disadvantages, Applications

Hello guys, welcome back to my blog. In this article, I will discuss what is slip ring induction motor, it’s working, the advantages of the motor, the disadvantages of the induction motor, applications of the induction motor, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- Top 10 Types Of Testing On Electrical Motors, Electrical Motor Testing

- Top Electric Drives Projects Lists For MTech & Engineering Students

- How To Calculate RPM Of DC And AC Motor, Formula To Calculate RPM

What Is Slip Ring Induction Motor

Introduction

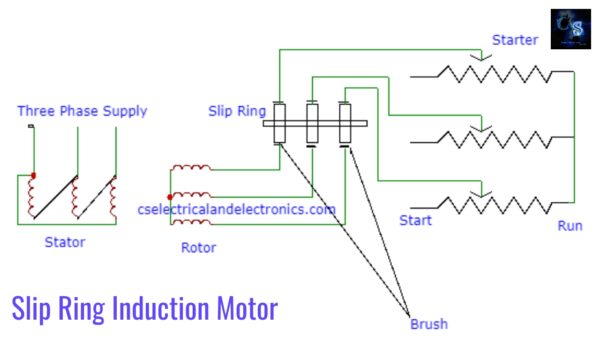

It’s an asynchronous motor, as the speed at which it operates will not be equal to the synchronous speed of the rotor. The rotor part of the slip ring induction motor is wound type. It’s cylindrical in shape that is laminated by a steel core and a semi-closed groove at the outer boundary to accommodate a 3 phase insulated winding circuit. The rotor will be wound to match the number of poles that are present in the stator. The terminals of the rotor and 3 start terminals connecting through slip rings are connected to the shaft. The shaft is required to transmit mechanical power.

Working Of Induction Motor Of Slip Ring Type

This motor works on the principle of Faraday’s law of electromagnetic induction. The stator winding will be excited by supplying AC power, which produces the magnetic flux.

Based on Faraday’s law the rotor winding will get induced and it generates a current of magnetic flux. The induced EMF will develop the torque. Due to this, the rotor starts to rotate.

The phase difference between the voltage and current does not meet the requirements to generate high starting torque because the torque developed is omnidirectional but not unidirectional.

The high valued external resistance is connected with the circuit, just to improve the phase difference of a motor. By connecting the inductive reactance and phase difference between current and voltage is reduced. This reduction makes the motor generate high starting torque.

Why Slip Rings Are Used

Slip can be defined as the difference between the flux speed and the rotor speed. In an induction motor, to produce torque, at least some difference should be there in between stator field speed and rotor speed. This difference can be called a slip. The slip ring improves the efficiency and performance of a motor by improving system operations and it eliminates wires that are dangling from motor joints. That’s why slip rings are used in the motor.

Speed Control Of Induction Motor

Effect of adding external resistance

The initiation of the slip ring induction motor occurs when it will draw full line voltage which is 6-7 times more than the full load current. This high current can be controlled by adding external resistance which will be connected in series with the rotor circuit. This external resistance will reduce high resistance when the motor obtains normal speed and it will increase the starting torque of a motor.

Using thyristor circuit

Thyristor on/off circuit is another method to control the speed of a motor. The rotor AC current will be connected to 3 phase bridge rectifier and connected to external resistance with the help of a filter. The thyristor will be connected across external resistance and is switched on/off at high frequency. On-time/off-time estimates the actual value of rotor circuit resistance, which helps to control the speed of a motor by controlling the characteristics of speed-torque.

Advantages Of Slip Ring Type Induction Motor

- Having high starting torque.

- Having the low starting current.

- Can take full load current up to 6-7 times higher.

Disadvantages Of Slip Ring Type Induction Motor

- High maintenance cost.

- Intricate construction.

- More copper loss.

- Less efficiency.

- Less power factor.

- More expensive.

Applications Of Slip Ring Type Induction Motor

- Can be used where high torque and low starting current is required.

- Used in elevator, and compressors.

- Used in cranes, conveyors, hoists, and more.

I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024