Top Ways To Detect The Transmission Line Conductor Damage

Hello guys, welcome back to our blog. Here in this article, we will discuss the top ways to detect transmission line conductor damage, or how an engineer will come to know whether an electrical line conductor is good to use or needs to be replaced.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read the following:

- Top 06 Portable Battery Scooty, Removable Battery EV Scooty In India

- Apple Will Fix The Overheating Issues With The iPhone 15 In The iOS 17 Software Update

- Top Upcoming AI Robots That Will Fuck Your Mind

Top Ways To Detect The Transmission Line Conductor Damage

A multitude of tools are available to facilitate the assessment of whether a transmission line conductor is suitable for continued use or necessitates replacement. Among these tools, some of the most prevalent ones include:

01. Visual Inspection:

The most straightforward and widely practiced method for scrutinizing transmission line conductors is visual inspection. Highly trained inspectors employ their expertise to meticulously examine the conductor’s surface, seeking visible indicators of degradation or impairment, such as the presence of corrosion, cracks, or noticeable dents.

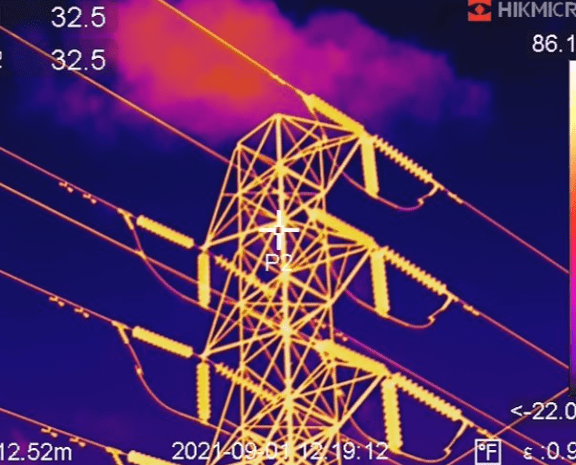

02. Infrared Thermography

Another invaluable tool in this endeavor is infrared thermography, which harnesses specialized infrared cameras to identify heat signatures on the conductor’s surface. Elevated temperatures detected through this method can serve as vital pointers to underlying problems, including corrosion, insecure connections, or other potential issues.

03. Ultrasonic Testing

An additional resource in the arsenal of conductor assessment tools is ultrasonic testing. This method relies on the deployment of ultrasonic waves to meticulously detect and pinpoint defects within the conductor, ranging from minute cracks to more substantial voids.

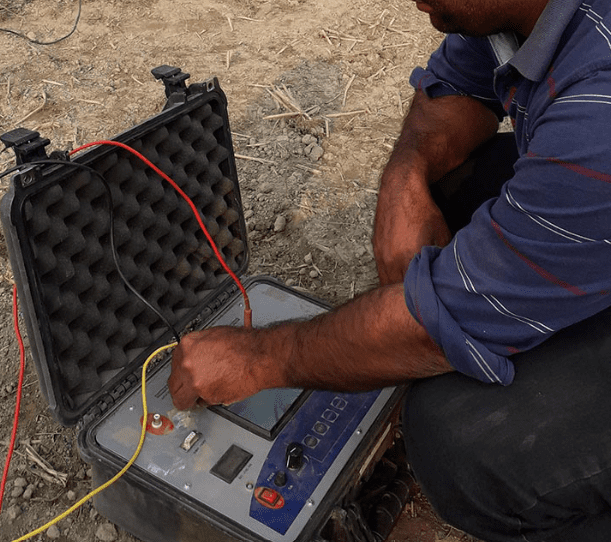

04. Electrical Resistance Testing

For an even more comprehensive analysis, electrical resistance testing comes into play. This method quantifies the electrical resistance of the conductor, and any significant increase in resistance can be interpreted as a telltale sign of corrosion or damage that warrants further investigation.

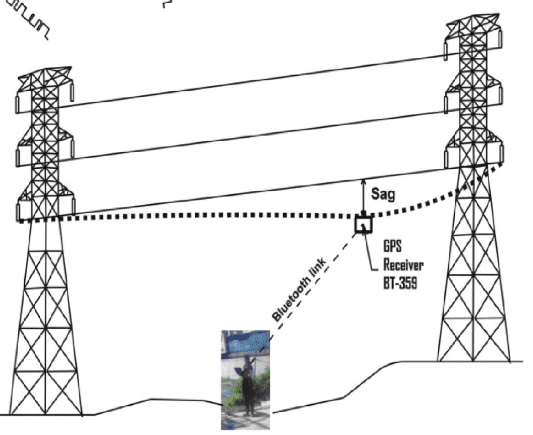

05. Line Sag Measurement

Monitoring the extent of sagging in the conductor is a crucial aspect of assessment, and line sag measurement tools fulfill this role adeptly. Any excessive sag detected can serve as a clear indicator of potential damage or ongoing deterioration, necessitating closer examination.

In tandem with the tools listed above, there exists a diverse array of specialized instruments designed for the meticulous inspection of transmission line conductors, including but not limited to:

01. Conductor Thickness Gauges: These highly specialized instruments are specifically engineered to precisely measure the thickness of the conductor. A decrease in thickness, when detected, may raise concerns of corrosion or wear and prompt further scrutiny.

02. Conductor Tension Gauges: Tension within the conductor is a critical parameter, and conductor tension gauges are indispensable tools for this purpose. Identifying loose conductors is of paramount importance due to the safety hazards they pose.

03. Conductor Vibration Monitors: Keeping a vigilant eye on conductor vibrations is another facet of conductor assessment, and conductor vibration monitors excel in this role. Excessive vibrations can lead to conductor fatigue and eventual failure, making monitoring a priority.

The choice of specific inspection tools is contingent on several variables, encompassing the type of conductor, the prevailing operating conditions, and the unique concerns of the utility provider.

Moreover, in addition to these tangible and mechanical tools, a spectrum of software applications has emerged to facilitate the in-depth analysis of transmission line conductor conditions. These software tools offer invaluable insights by identifying potential issues, including sagging, excessive vibration, and overheating.

By orchestrating the harmonious integration of both physical tools and software, utility companies can attain a truly comprehensive assessment of the state of their transmission line conductors. This, in turn, empowers them to make judicious and well-informed decisions regarding the timing of conductor replacements, thus ensuring the reliability and safety of their power transmission infrastructure.

This was about “Top Ways To Detect The Transmission Line Conductor Damage“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2024 Is About To End, Let’s Recall Electric Vehicles Launched In 2024