Hello guys, welcome back to my blog. In this article, I will discuss what is AUTOSAR, motivation, benefits of using AUTOSAR for manufacturers, suppliers, and tool developers, partnerships, types of partnerships in AUTOSAR, drawbacks, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- Top Applications Of CAN, LIN, Ethernet, FlexRay, USB, & Their Speed

- Types Of Automotive Sensors and Actuators Used In Electric Vehicles

- Why ECU Is Used In Cars, Working Of Electronic Control Unit, Benefits

What Is AUTOSAR

AUTOSAR stands for AUTomotive Open System ARchitecture (AUTOSAR). It is standard software that is used in the automobile industry.

Motivation

Today, the progress of electronic control units (ECUs) is characterized by several driving factors:

- Requirements for more services, safety, economy, and comfort

- Rising complexity due to higher ECUs and the increase in sharing software and functionality

- More increased variety of ECU hardware and networks such as controller area network [CAN], FlexRay, local interconnect network [LIN], MOST, etc.

As a result of these driving circumstances, communication between ECUs is growing. Regrettably, the ECU networks are adapted for the distribution of automotive functions which, notwithstanding the fact that it has been growing for some time, is yet not structured with respect to the latest technologies. The ECUs are arranged into several subdomains, for example, power train, body, telematics, chassis, etc. Before AUTomotive Open System ARchitecture (AUTOSAR), the networks of ECUs held neither standardized in accordance with their interfaces over these subdomain borders nor formed with respect to the interrelationships between the nodes of the network.

Similar statements can be made for the growth processes. The software development methods for various ECUs grew according to the unusual history of the sub-domains and were quite different for a long time. In the automotive industry, most of the comprehensive system development methods assign functional requirements to software and hardware parts on a one-to-one basis.

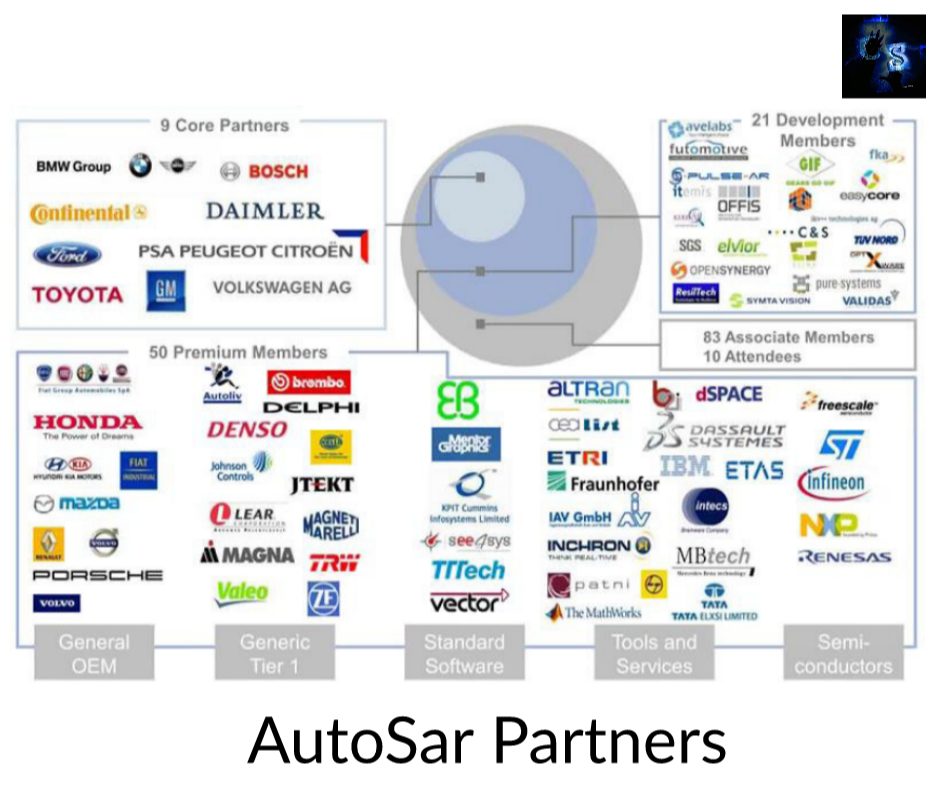

Setting up AUTOSAR

With regard to this background, the leading automobile organizations and their first-tier suppliers created a partnership in 2003. This partnership has set an industry-wide standard for the automobile electronic, AUTOSAR, which is managed by the following ten “core partners”: BMW Group, Bosch, Continental, General Motors, PSA Peugeot Citroen, DaimlerChrysler, Ford Motor Company Siemens VDO, Toyota Motor Corporation, and Volkswagen. The first stage of AUTOSAR began in 2003 and stopped in 2006.

During this stage, 52 “premium members,” companies of the suppliers, and software and semiconductor manufacturers joined the growth of this standard and made significant contributions to the consortium. In addition to these premium members, there are “development members,” “associate members,” and “attendees,” whose roles in AUTOSAR diversified with respect to their contribution and exploitation (www.autosar.org).

The first stage of AUTOSAR closed at the end of 2006, and the beginning AUTOSAR products were made accessible on the market. The members of AUTOSAR accept that AUTOSAR makes it feasible to manage the complexity of the electrical and electronic parts, together with an improvement in quality and profitability. The prospect of automotive engineering is in these modular and scalable AUTOSAR software architectures.

Partnership

The partnership will actively connect 3rd parties in its growth by means of several deals, which will have special roles and duties connected with them. The partnership has chosen a 3-tier partnership structure which has been shown in similar initiatives. Every tier of the partnership has special rights and responsibilities which are described in relevant agreements. Such 3rd parties may have commercial supply or demand side relations with the partners and their admission will be allowed throughout the AUTOSAR project development cycle.

Benefits Partnership

The fulfillment of the AUTOSAR industry standard will give important benefits for OEMs, leading suppliers as well as for tool providers and new market players.

Benefits for OEM:

• Establish growth distribution with suppliers

• Compete on innovative faculty with extended design flexibility

• Simplify software and system integration

• Decrease overall software development costs

Benefits for a supplier:

• Decrease version proliferation

• Reuse software modules over OEMs

• Raise the efficiency of application improvement

• Create new business designs

Benefits for tool provider:

• Interface with expansion processes

• Install tools into an overall tool environment

Benefits for new market entrants:

• Enable new business models by means of standardized interfaces

Types Of Partnership

The partnership will involve 3rd parties in the development of AUTOSAR via the following types of partnership:

- Premium Partners

- Development Partners

- Associate Partners

- Attendees

Premium Partners

Every partner has rights and responsibilities in the development partnership. The rights of a Premium Partner are as follows:

- Right to utilize the AUTOSAR technology authority-free and by a free-of-charge license for automotive purposes

- Access to current data and specifications

- The leadership of and association in working groups

- Free of cost access to AUTOSAR associated IP of all other AUTOSAR partners

The Premium Partner has to assign a team with such skills as is needed in the participating working group. To reach the objectives of the working group, the Premium Partner offers a work package related to Intellectual properties.

Development Partners

Every partner has rights and responsibilities in the development partnership. The rights of a Development Partner are as follows:

• Freedom to utilize the AUTOSAR technology authority-free and with a free-of-charge license for automotive purposes

• Access to current data and specifications

• Participation in working groups

• Access to AUTOSAR associated IP of all other AUTOSAR partners free of cost

The Development Partner has to assign a team with such skills as is needed in the participating operation group. To reach the targets of the working group, the Development Partner provides a work package related to Intellectual Properties.

Associate Partners

Every partner has rights and responsibilities in the development partnership. The rights of an Associate Partner are as follows:

• Right to utilize the AUTOSAR technology authority-free and with a free-of-charge license for automotive purposes

• Access to data and the results of the development via administrator or homepage

Attendees

Each Attendee has rights and responsibilities in the development partnership. The rights of an Attendee are as follows:

• Access to present and relevant message and specifications

• Cooperation in working groups

Objectives of AUTOSAR

The main source of AUTOSAR is “cooperate on standards, fight on implementation.” So, the members built a set of main aspirations, which also wanted to be standardized because they were not recognized as primary factors for competitiveness.

- Consideration of availability and security requirements

- Redundancy activation

- Scalability to various vehicle and platform variants

- Implementation and uniformity of basic functions as an industry-wide “standard core” solution

- Transferability of functions from one ECU to different within the network of ECUs

- Combination of functional modules from various suppliers

- Maintainability during the whole product growth cycle

- Improved use of commercial-off-the-shelf (COTS) hardware

- Software updates and upgrades over vehicle life.

On all levels of modeling, an object-oriented eXtensible Markup Language (XML) class model, specified in UML2.0, is used. Beginning with the analysis of the description language you have to go down (via the meta model-level) to a concrete user model, which can be recognized as a concrete XML file.

What are the advantages of using AUTOSAR for manufacturers, suppliers, tool developers?

General benefits:

- Increased re-use of software,

- Increased design versatility, Clear layout rules for integration

- Minimization of costs for software growth and service in the long term

- Focus on protected, innovative, and competitive functions

Specific benefits for OEMs:

- Functions of competitive nature can be formed separately

- Later sharing of innovations is available

- Standardized conformance process

Specific benefits for suppliers:

- Reduction of version proliferation

- Progress sharing among suppliers

- Improvement of efficiency in functional development

- New business models

- Preparation for the upcoming development in software volume

Specific benefits for tool developers:

- Common interfaces with growth processes

- Seamless, flexible, task optimized (time-dependent) tool landscape

Specific benefits for new market entrants:

- Transparent and defined interfaces allow new business models

- Manifest contractual task allocation and outsourcing of software-implementation approachable

Drawbacks of AUTOSAR

The methodology employed for mapping AUTOSAR concepts on existing has serious drawbacks.

01. If both the current concept and the recently launched AUTOSAR are thought to carry the same data, there is a risk of inequality. There is also a risk of uncertainty over which thoughts to use, but this is quickly resolved by addressing the old concept abstract whereby forcing the use of the new concept.

02. Conflicting inheritance. Moreover, if individual thoughts map well on each other, they can be members of inheritance structures breaking AUTOSAR. On behalf of multiplied data and the risk of disagreement, the problem can probably be fixed with multiple inheritances. In practice the problems cannot be fixed; System Weaver does not encourage multiple inheritances.

The closing part of the implementation of the prototype meta-in an actual meta-model is more of an exhibit piece; the implementation is what normally is called an “ugly hack” In order to achieve a fully operating AUTOSAR meta-model the general customization of the System Weaver is important, not only with respect of customers requirements but also with respect to AUTOSAR´s requirements.

I hope this article may help you all a lot. Thank you for reading. If you have any doubts related to this article, then click on ask question to add your question – Ask Question.

Also, read:

- 10 Free ADAS Projects With Source Code And Documentation – Learn & Build Today

- 100 + Electrical Engineering Projects For Students, Engineers

- 100+ Indian Startups & What They Are Building

- 1000+ Automotive Interview Questions With Answers

- 1000+ Electronics Projects For Engineers, Diploma, MTech Students

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 2026 Hackathons That Can Change Your Tech Career Forever

- 50 Advanced Level Interview Questions On CAPL Scripting