DC Motor, Advantages, Disadvantages, Applications, Working

Hello guys, welcome back to my blog. In this article, I will discuss DC motor, the advantages of DC motor, the disadvantages of DC_motor, applications of DC_motor, working of DC_motor, construction of DC motor, etc.

If you have any doubts related to electrical, electronics, and computer science, then ask question. You can also catch me @ Instagram – Chetan Shidling.

Also, read:

- Universal Motor, Advantages, Disadvantages, Applications, Working.

- Stepper Motor, Advantages, Disadvantages, Applications, Working.

- Top 10 Best Ceiling Fans For Home, Shop, School, Colleges.

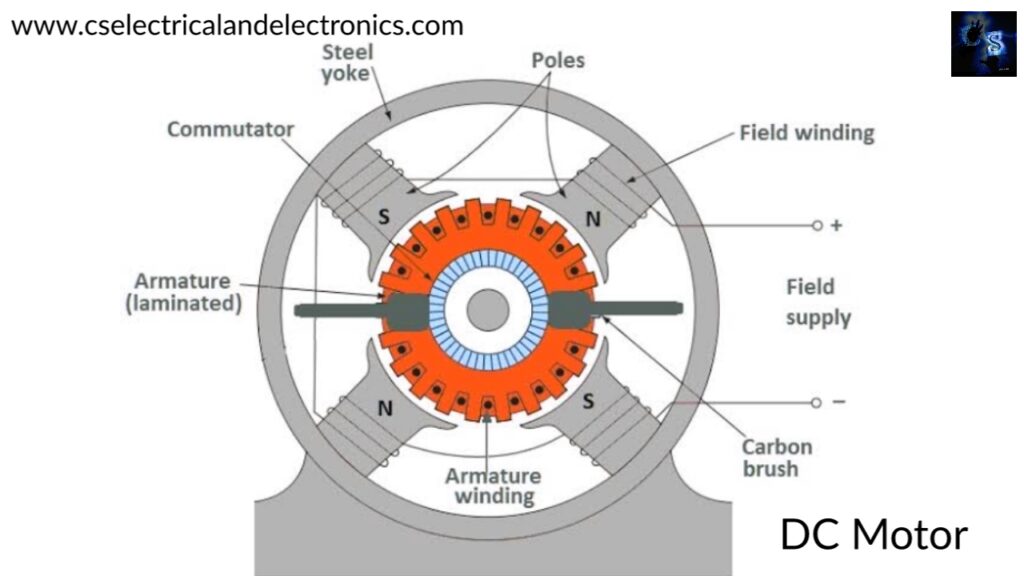

DC Motor

The conversion of electrical energy to mechanical energy is known as the motor. There will not be any differences between a DC motor and a dc generator according to the construction. Parts in DC motor – Click here to read the complete information.

Working principle Of DC Motor

Motor works on the principle of Loretz force principle. Whenever a current-carrying conductor placed in a magnetic field then there will be a force produced in the conductor. The two fluxes oppose each other. Here, the field flux is produced by the field winding and the armature flux is produced by the armature winding when the armature is given an electric input.

We know that every current-carrying conductor will produce flux. Therefore, the armature current will also produce flux. The direction of the flux produced by the armature conductor is determined by the right-hand thumb rule and the direction of the armature conductor can be determined.

These two fluxes i.e., armature flux and main field flux will interact with each other by which the net flux will be increased towards one side and which will be minimum on the other side.

The increased flux on one side will be in the shape of an enlarged magnetic field or flux or like a stretched rubber band. Therefore, this will exert a force on the surface of the conductor by which there will be momentum in the conductor.

As the armature is in a cylindrical shape and has a radius, therefore, a force will be created on the surface of the armature which leads to turning or twisting which is called as production of torque.

As the flux is zero the speed is infinity and the motor mechanically gets damaged. The speed of the motor can be varied up to two times. We should not run the series motor at no-load conditions.

Under light load conditions, the current drawn by the series motor will be very very small and therefore the speed of the motor will be very very high which may lead to mechanical damage to the motor. So, the series motor should not be operated under light load or no-load conditions.

Significance of Back EMF

When the motor is operating then the concept of generator comes into the picture i.e., whenever the flux linking with the conductor changes then there will be an induced emf in the conductor. Here, the flux produced by the poles will be stationary and constant and because of the motor principle, the armature starts rotating.

Because the armature starts rotating the flux produced by the main field will be cut by the armature conductor and therefore there will be an induced emf in the armature conductor according to the generator principle.

We know that the direction of the induced emf produced by the motor is opposite to the applied voltage. But the magnitude of the induced emf will be similar to that of the induced emf of the generator.

Types of DC motors

Depending upon filed winding DC motors are classified into three types. They are

01. Series motor

02. Shunt motor

03. Compound motor

- Long shunt compound motor

- Short shunt compound motor

01. Series DC motor:-

Series DC motor has high starting torque and variable speed. Ex:-conveyers, cranes, elevators etc.

02. Shunt DC motor:-

Shunt DC motor has constant speed and medium starting torque. Ex:-Milling machines, blowers, fans etc.

03. Compound DC motor:-

These motors have relatively high starting torque. Ex:-Shears, rolling mills etc.

Advantages Of DC Motor

- DC motors are smaller in size.

- These motors operate on DC supply then they can be used in electronics devices.

- DC motors are suitable for traction systems for driving heavy loads.

- DC series motors have will high starting torque.

- Wide range of speed control.

- DC Shunt motors are best suited for armature control and field control.

- DC motors have quick starting, stopping, reversing, and fast acceleration.

- DC motors are free from harmonics.

Disadvantages Of DC Motor

- DC motors have a high initial cost.

- Maintenance cost is high and increased operation due to the presence of brushes and commutator.

- Due to sparking at brush DC motors cannot operate in explosive and hazardous conditions.

- As the speed increases, the shaft gets vibrated and the armature gets damaged.

- We need converters to supply power to the motor.

Applications Of DC Motor

- DC series motors are used where high starting torque is required and variation of speed is possible. Series motors are used in traction systems, cranes, air compressors, vacuum compressors, sewing machines, etc.

- Shunt motors are a special type of motor used where constant speed is required. These motors are used in blowers, weaving machines, spinning machines, lifts, etc.

I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 50 Tips To Save Electricity At Home, Shop, Industry, Office

Author Profile

- Content Writer