What Is CPC (Common Powertrain Controller) ECU, Working of CPC

Hello guys, welcome back to our blog. Here in this article, we will discuss what is CPC (common powertrain controller) is, the working of a CPC, and how it is different from other ECUs.

Ask questions if you have any electrical, electronics, or computer science doubts. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- What Is HiL, Hardware In Loop, Working, Tools Used In HiL

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- Top 10 High Paying Electrical And Electronics Jobs In 2023, 2024

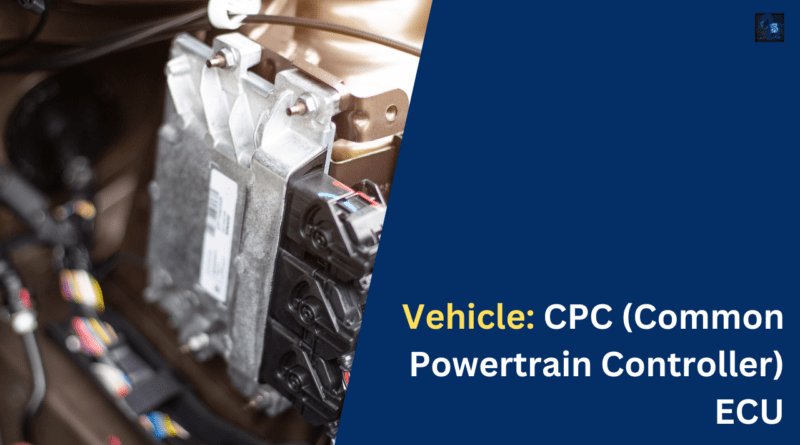

CPC (Common Powertrain Controller) ECU

Introduction

Modern cars are built around a Common Powertrain Controller (CPC), which acts as a centralized control unit to coordinate the powertrain, electronic systems, and operational controls of the vehicle. The CPC is a complex electronic module that plays a crucial role in automotive technology. Its job is to integrate, manage, and coordinate various vehicle activities. Its primary function is to integrate communication between the several electronic parts of the car.

Fundamentally, the CPC is an integration center that combines inputs from a wide range of sensors located all throughout the car. Comprehensive monitoring and control of crucial characteristics, such as engine performance, gearbox behavior, emissions regulation, and safety system integration, are made possible by this convergence. As the brains of the vehicle, it processes sensor inputs and sends commands to optimize performance depending on operator inputs and real-time data.

Ensuring optimal operational efficiency and compliance with strict regulatory criteria is one of the CPC module’s main goals. The CPC is essential to keeping the vehicle compliant with safety and environmental requirements since it manages crucial tasks pertaining to emissions management, engine performance, and system integration. It also makes a major contribution to improving emissions reduction, fuel efficiency, and overall vehicle performance.

Beyond command and regulation, the CPC can also be used for diagnostic purposes, saving important information about the functioning and performance of the vehicle. During diagnostics, this data is an essential tool that specialists use to efficiently identify and resolve problems. The development of the module is a major milestone in automotive technology, encapsulating developments in electronic control systems and their critical function in controlling and optimizing the many functions of contemporary automobiles. In the end, the CPC is a technical pillar that combines intricate electronic coordination and control to guarantee smooth functioning and effectiveness in a variety of vehicle environments.

Definition of CPC (Common Powertrain Controller) ECU

In a vehicle, a CPC module acts as a centralized controller that integrates, manages, and synchronizes communication amongst vehicle systems, operator controls, and powertrain components. It serves as a link between the many electronic systems in a car.

Working of CPC (Common Powertrain Controller) ECU

The central nervous system of an automobile’s electronic system is the CPC module. It gets information from sensors positioned all around the car, including ones that deal with the fuel system, braking system, engine, gearbox, and more. To carry out commands and modify the powertrain’s and other integrated systems’ parameters and operations, these inputs are analyzed and interpreted. To guarantee the best possible vehicle performance, the module has two-way communication, issuing commands to different parts and receiving feedback in return.

01. Centralized Control Hub:

Fundamentally, a CPC module functions as the brain that controls the engine and electronic systems of a car. It takes data from a variety of sensors positioned all over the car and uses that information to operate as a sophisticated controller. Critical parameters such as engine speed, fuel level, brake status, throttle position, temperature, and wheel speed are monitored by these sensors.

02. Data Processing and Interpretation:

The CPC module uses embedded software and algorithms to process the data it receives from the sensors. In order to make wise choices about how to operate the car, it evaluates the data. This includes controlling emissions, engine performance, gearbox behavior, and safety system interaction.

03. Integration with Engine Control Module (ECM):

The CPC module’s significant communication with the Engine Control Module (ECM) is one of its main purposes. In order to regulate the engine’s operations, including fuel injection and ignition timing as well as emission-related systems like catalytic converters and exhaust gas recirculation, it receives and delivers signals.

04. Transmission Control:

Based on the acquired sensor data, the CPC controls transmission functions for cars with automatic gearboxes. It optimizes performance and fuel efficiency by managing torque converter lockup, gear changing, and other transmission-related behaviors.

05. Vehicle System Coordination:

The braking system, accelerator pedal, fuel gauge, odometer, and other systems of the car are all interfaced with the CPC module. In order to provide seamless coordination between the driver’s inputs and the vehicle’s functioning, it reads signals from several systems.

06. Safety Systems Integration:

The CPC may be connected to safety systems like as anti-lock braking, stability control, and traction control. In order to improve vehicle stability and safety under various driving situations, it gathers and analyses data from these safety systems and makes real-time modifications.

07. Diagnostics and Maintenance:

Data about the performance and operation of the vehicle is frequently stored in the CPC module. With the use of this data, technicians can diagnose problems, assess how the car behaves, and carry out any required maintenance or repairs.

08. Communication Gateway:

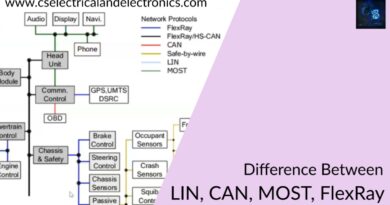

In contemporary automobiles including numerous control units and electronic systems, the CPC may serve as a communication intermediary. It makes data sharing between different onboard systems possible, guaranteeing smooth coordination and communication.

The importance of CPC modules is found in their capacity to maximize vehicle performance, guarantee legal compliance, improve safety, and boost overall effectiveness. However, their operation necessitates precise hardware integration and sophisticated software algorithms due to the extensive network of sensors, actuators, and systems they manage.

CPC modules, which combine the control and coordination of multiple systems inside a vehicle, mark a significant advancement in automotive technology. The critical function these modules play in the automobile industry is demonstrated by the optimal performance, efficiency, and safety that modern vehicles are able to accomplish because of their precise workings.

This was about “CPC (Common Powertrain Controller) ECU“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 50 Tips To Save Electricity At Home, Shop, Industry, Office

Author Profile

- Chetu

- Interest's ~ Engineering | Entrepreneurship | Politics | History | Travelling | Content Writing | Technology | Cooking

Latest entries

All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry

All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose,

All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose, All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers

All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers All PostsMarch 22, 2024Driver Monitoring Systems In Vehicles, Working, Driver Sleepy Alert

All PostsMarch 22, 2024Driver Monitoring Systems In Vehicles, Working, Driver Sleepy Alert