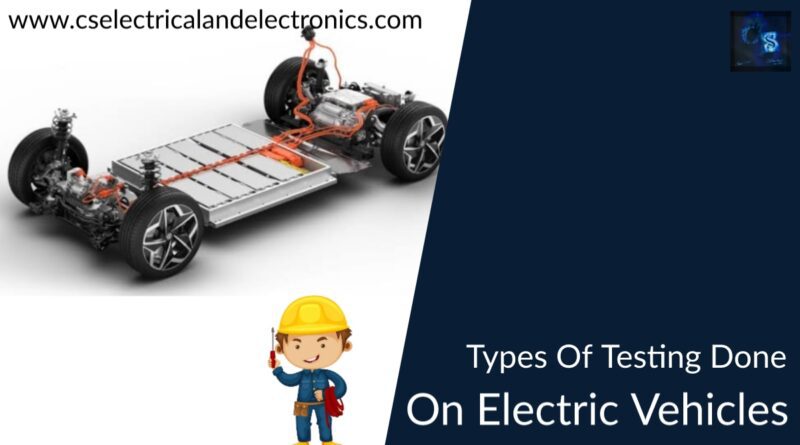

Types Of Testing Done On Electric Vehicles Before Launching

Hello guys, welcome back to our blog. Here in this article, we will discuss the types of testing done on electric vehicles before launching in the market, why testing is needed, and the advantages of testing electric vehicles.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- Top 10 BMS Manufacturing Companies In The World, Battery Management System

- What Is HVIL, High Voltage Interlock, Working, Purpose Of Using

- How To Avoid Thermal Runaway In Electric Vehicles, EV Bikes, EV Car

Types Of Testing Done On Electric Vehicles

Have you ever wondered what tests the most popular EV must pass in order to be allowed to drive? The information in the following article will answer all of your questions. The landscape of electric vehicles includes testing and certification.

Electric vehicles unite the automotive industry (ISO standards) with the electrical industry, two formerly disparate worlds from the testing and certification standpoint (IEC standards).

Beyond homologation testing for the vehicles and their parts, testing for electric vehicles is conducted. It also encompasses the systems that enable communication between EVs, charging stations, and back-office systems as well as the charging interfaces and related technologies.

Advantages of testing electric vehicles

- Make sure that people, equipment, and infrastructure are all electrically safe.

- Make sure your products adhere to the standards.

- Examine your goods’ compliance, operability, and electromagnetic compatibility.

- Enables you to advertise your goods in several international markets

Introduction to electric vehicles:

In fact, the internal combustion engine predated the development of electric vehicles (EVs) in the late 19th century. But now, several years later, the e-mobility trend is really accelerating. Why is the tipping point happening now, then? Three things are accelerating the switch to electric vehicles:

- Stricter environmental laws (restrictions on CO2 emissions imposed on vehicle manufacturers and vehicle owners)

- Technological progress (e.g. cheaper and more powerful batteries, and infrastructure for faster charging)

- Altering consumer habits (growing environmental awareness and acceptance of EVs)

Certification and Testing of Electric Vehicles

The testing of electric vehicles (EVs) goes well beyond the homologation testing of the cars and the parts. It also includes the interoperability or conformity testing of the charging interfaces and related technologies that allow communication between EVs, charging stations, and back-office systems. Large numbers of battery cells found in battery packs and the modules from which they are constructed make them a potential hazard and require testing as well. Additionally, all electrical devices are tested for conformity.

The testing of plugs, cables, connectors, cabling, and switches is a crucial stage for electric vehicles.

Types Of Testing Done On Electric Vehicles

The different tests that are performed on the EV are:

- Electrical safety testing

- Performance testing

- Conformance and interoperability testing

- Functional safety testing

- EMC testing

- Wireless testing

- Cyber security testing

- Software testing

- Environmental & stress testing

- Chemical testing

EV testing and drive cycles

When taking into account the effects of fluctuating external conditions, such as wind speed and direction, temperature, and rising and descending slopes, measuring the performance and efficiency of EVs is a challenging process. All of these provide testing difficulties and may greatly affect a vehicle’s energy usage and testing results for driving range.

The use of a chassis dynamometer, a tool that can measure stresses on a car’s wheels or engine, can solve many of these issues. Some cutting-edge chassis dynamometers can simulate driving in real-world road conditions and are computer controlled.

In order to test emissions uniformly on passenger automobiles with combustion engines, drive cycle testing was created in the late 1960s. Drive cycle testing is often carried out on a calibrated chassis dynamometer to offer a stable, climate-controlled, and traffic-free environment. A drive cycle mimics a typical driving pattern of motor vehicle users.

For a particular vehicle test, the (typically human) test driver of the motor vehicle must adhere to the predetermined speed and acceleration profiles used in drive cycles. A computerized driving aid helps the driver maintain the necessary profiles by displaying the car’s rate of acceleration and deceleration as well as the operational circumstances of the vehicle to produce a legitimate test drive.

Meeting these operational requirements is essential since vehicle speed, acceleration, and deceleration rates have a significant impact on test results and vehicle emissions, energy use, and other factors.

Electric vehicle on-board network electrical safety – insulation monitoring

While the vehicle is in motion, the “Voltage Class B On-Board Network,” an electrical vehicle’s power supply system, can be thought of as an isolated power supply system. Finding insulation issues early on is one of the main challenges. Normal operation can result in insulation problems for a variety of reasons, including contamination, salt, humidity, bad connectors, mechanical effects, etc.

What are the requirements of the standard? – n ISO6469-3:2011

Road vehicles powered by electricity: safety requirements- Part 3: Electric shock protection for people “the onboard minimum insulation resistance Throughout the service, the network must be maintained. life and in all operational circumstances “. The ideal response: Continuous measurement of insulating resistance using Series IR155 or iso165C of ISOMETER®

Performance test on the EV

Electric mobility offers a solution to the current issues with transportation, such as inefficiency and pollution; yet, autonomy poses challenges because batteries have a limited amount of energy storage capacity. In light of these potential influences, it is vital to maximize the performance of electric vehicles in urban areas.

The range of the car is dependent on the temperature, the kind of road, the acceleration, the velocity, the topography, and the use of auxiliary services, according to research done on EVs in other cities (heating, and air conditioning). These factors are determined by each city’s urban environment.

Conformance and interoperability testing

By exchanging information and managing processes, charging interoperability refers to the capacity to link electric vehicles and power supply equipment of the same or different models and versions for the purpose of providing power. To overcome the charging interoperability issue, which affects all three components of the EV charging system—the EV, charging facilities, and connecting devices—good cooperation is required.

Functional safety testing

The functional safety standard ISO 26262 for electrical or electronic systems is widely accepted. For E/E systems relevant to safety, this standard is applicable throughout the whole car lifecycle. The mechanical subsystem in the automobile industry as well as other embedded systems in any vehicle that has driver safety assistance, propulsion, or control systems are also covered by the standard.

This safety standard tackles the potential safety risks brought on by E/E system malfunctions. This 12-part standard covers all functional safety-related aspects of product development.

EMC testing

When discussing electromagnetic compatibility, it’s important to remember that an electromagnetic field, or EMF, is made up of both an electric (E) and a magnetic (H) field. These two fields only combine to form an EMF when it is far from the source (and, as a fun fact, with a fixed V/I relationship of 377 ).

Although the distance at which this merging takes place is not formally defined, it is typically thought to be between 1-3. (wavelengths). Depending on the circuit circumstances, one or the other will predominate closer in (also known as the “near field”): Fast varying voltages (high dV/dt) cause E-fields, whereas rapidly varying currents (high dI/dt) cause H-fields.

In the case of EMC concerns, it may be argued that the best course of action is to avoid creating inadvertent antennas, as is the case with many complex situations (to paraphrase H.L. Mencken). While this is undoubtedly true, it isn’t particularly useful advice on its own because practically anything conductive can be transformed into an antenna, and even things you wouldn’t think might be a problem—like a seam in a metal enclosure—may end up being the worst hassles of all! A more practical, though still broad, set of recommendations might be:

- Reduce the loop size of any conductors with a high dI/dt capability or low impedance, such as wires, traces, bus bars, etc.

- Reduce the surface area of any conductors that have high dV/dt or high impedance, and/or protect them.

- Avoid switching more quickly than necessary in order to maximize efficiency or data rate (digital logic) (power conversion).

- Any conductive surface with a hole, slot, or seam can also function as an antenna.

This was about “Types Of Testing Done On Electric Vehicles“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 50 Tips To Save Electricity At Home, Shop, Industry, Office

Author Profile

- Chetu

- Interest's ~ Engineering | Entrepreneurship | Politics | History | Travelling | Content Writing | Technology | Cooking

Latest entries

All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry

All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose,

All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose, All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers

All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers All PostsMarch 22, 2024Driver Monitoring Systems In Vehicles, Working, Driver Sleepy Alert

All PostsMarch 22, 2024Driver Monitoring Systems In Vehicles, Working, Driver Sleepy Alert