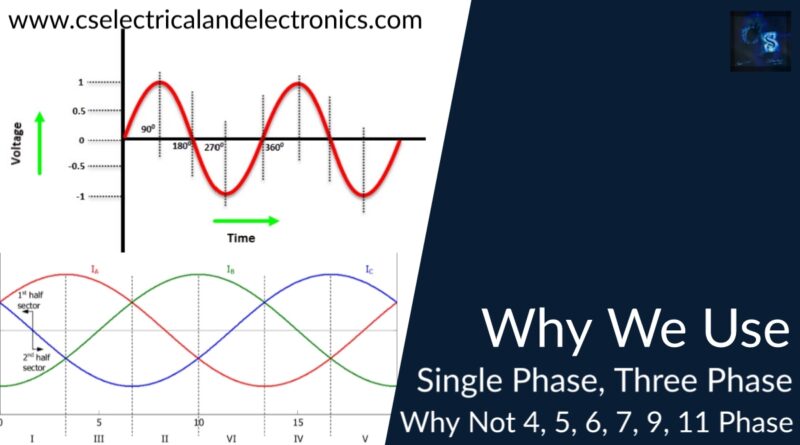

Why We Use Single Phase, Three Phase, Why Not 4, 5, 6, 7, 9, 11 Phase

Hello guys, welcome back to my blog. In this article, I will discuss why we use single phase and three-phase supply, why not 4, 5, 6, 7, 8, 9. 10, 11, 12, 13, etc, and we will also discuss which phase is best to use.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics.

Also, read:

- What Is Electric Drive, Working, Applications, Advantages, Disadvantages.

- What Is Smart Grid, Working, Applications, Requirements Of Smart Grid.

- Cost Of Electric Cars In USD And Indian Rupees, Electric Car Price.

Why We Use Single Phase, Three Phase

Single-phase and three-phase power supply systems are the two most common forms of power supply systems. Single-phase power is utilized in places where less power is needed and to power modest loads. When a big amount of power is required, the three phases are used in major enterprises, factories, and manufacturing units.

There appears to be no inherent less-costly number of phases because the overall power capacity increases by one line-ground voltage times one line current for each phase added. There were “economic” justifications for six-phase systems decades ago, but the justification for six-phases was that power transfer could be doubled on a constricted right-of-way utilizing a single six-phase transmission line. It’s worth noting that the line-to-line voltage in a six-phase system is the same as the line-to-ground voltage.

One of the most significant differences between single-phase and three-phase power is that single-phase power has only one conductor and one neutral wire, whereas three-phase power has three conductors and one neutral wire.

Because it is relatively simple and affordable to install, single-phase power is used in most households and small businesses. Three-phase power is more efficient and less expensive to operate for commercial and industrial organizations with higher electrical consumption.

Suitable for motors up to 5 horsepower; a single phase motor consumes substantially more current than a three-phase motor, making three-phase electricity the most efficient option for industrial applications.

The phase angle between transmission lines in a three-phase system is 360/3=120 degrees. As the number of phases grows, the phase difference decreases, necessitating a greater number of transpositions. It has an impact on the cost of transmission tower installation. Large corporations, as well as industry and manufacturing, use it all over the world. Converting from a single-phase installation to a three-phase is costly, but it allows for smaller, less expensive wiring and lower voltages, making it safer and less expensive to operate. For equipment built to run in three phases, it is extremely efficient.

Going from one to three phases results in a 50 percent gain in efficiency (which can be utilized toward reducing copper by 75 percent ). Increasing the number of phases beyond that (infinite) will only result in a minor increase in efficiency (something of the order of 7 percent ). This is merely a comparison of efficiency. In any event, using three phases allows you to generate three times the power of a single-phase generator (assuming you generate the same voltage and current in each phase as a single-phase generator) and so on.

When looking at higher phases in multiples of three, such as 6,12, or higher lines, the power transfer curve would be declining, for example. Six phases add twice the power of three phases, however, twelve phases do not add twice the power of six phases. Higher phases would also put more demand on the system.

When we talk about India’s current distribution and generation infrastructure, it is set for three phases, and increasing the phase requires changing the generator structure. Another issue is that transmitting six/nine phases requires more conductor, pole structure, and all protective equipment, as well as a transformer, making it difficult to monitor each phase and locate faults.

When we extract the power delivery expression, we see that in a three-phase system, the reactive components balance out and the maximum power is delivered. The effectiveness of the system improves as the number of phases increases, but the cost of conductors and the difficulty of achieving higher phases (more than 3) increases as well.

We can make a three-phase system by simply adding one extra conductor to a single-phase system. Only in a three-phase system do all phases deliver the same amount of power. If the phases are balanced, they are displaced at a 120-degree angle. The variation in delivered power between 3, 4, 6, and 12 phases is minimal.

Even number phases aren’t ideal since they can cancel out parameter components, resulting in insufficient power on the receiving end. The design of a 4,5 or more phase transformer is complicated and expensive.

Three-phase power generation and delivery are more efficient than two-phase power generation and delivery, which is more efficient than one-phase power generation and delivery. Similarly, increasing the number of phases improves efficiency; for example, 4 phases are more efficient than 3 phases, and 5 phases are more efficient than 4 phases, and so on. The rise in efficiency as the number of phases rises is because the power supply becomes more consistent as the number of phases rises.

A single-phase power supply will have zero instantaneous power twice a cycle, but there will be no zero instantaneous power in the case of 3 phase power and higher phase numbers, resulting in more smooth power delivery as phases increase. It is simple to calculate that three-phase delivery is 150 percent more efficient than single-phase delivery. This is the best option since the enhanced efficiency of utilizing more phases does not justify the additional complexity of employing more phases.

We chose 3-phase systems because the torque of large 3-phase motors and generators is constant, eliminating oscillating torques that might damage the huge motor or generator shafts, as I explained before. Triple phase systems (3, 6, 9,.) give constant torque, however, 3-phase is the simplest (smallest number of phases) system that gives constant motor/generator torque. As a result, systems with more than three phases appear to be extremely complicated, and no one will be interested in adopting them.

This was about “Why We Use Single Phase, Three Phase“.I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 50 Tips To Save Electricity At Home, Shop, Industry, Office

Author Profile

- Content Writer

Latest entries

All PostsAugust 25, 2021Top 16 Highest Paying Engineering Jobs in the USA For Freshers

All PostsAugust 25, 2021Top 16 Highest Paying Engineering Jobs in the USA For Freshers All PostsAugust 23, 2021Top 10 Smart Cities In The World, Best Cities To Visit In The World

All PostsAugust 23, 2021Top 10 Smart Cities In The World, Best Cities To Visit In The World All PostsAugust 21, 2021Top 20 VLSI & Embedded Systems Projects for Mtech Students

All PostsAugust 21, 2021Top 20 VLSI & Embedded Systems Projects for Mtech Students All PostsAugust 21, 2021Top 20 Power Systems Projects For MTech Students, Engineering Students

All PostsAugust 21, 2021Top 20 Power Systems Projects For MTech Students, Engineering Students